Why Moisture Is Your Worst Enemy in Compressed Air Systems

Compressed air is essential in countless industries—from manufacturing and food processing to automotive and pharmaceutical applications. But there’s one persistent problem: moisture. Water vapor in compressed air can lead to:

⚠️ Pipe corrosion

⚠️ Rusted pneumatic tools

⚠️ Malfunctioning valves

⚠️ Contaminated products

⚠️ Increased maintenance costs

That’s where the air compressor desiccant dryer becomes indispensable. Unlike refrigerated dryers, desiccant dryers provide ultra-low dew points, often down to -40°F or lower, making them perfect for sensitive or cold-climate applications.

In this guide, we’ll explain how an air compressor desiccant dryer works, what makes it unique, and why it should be part of every high-performance compressed air system.

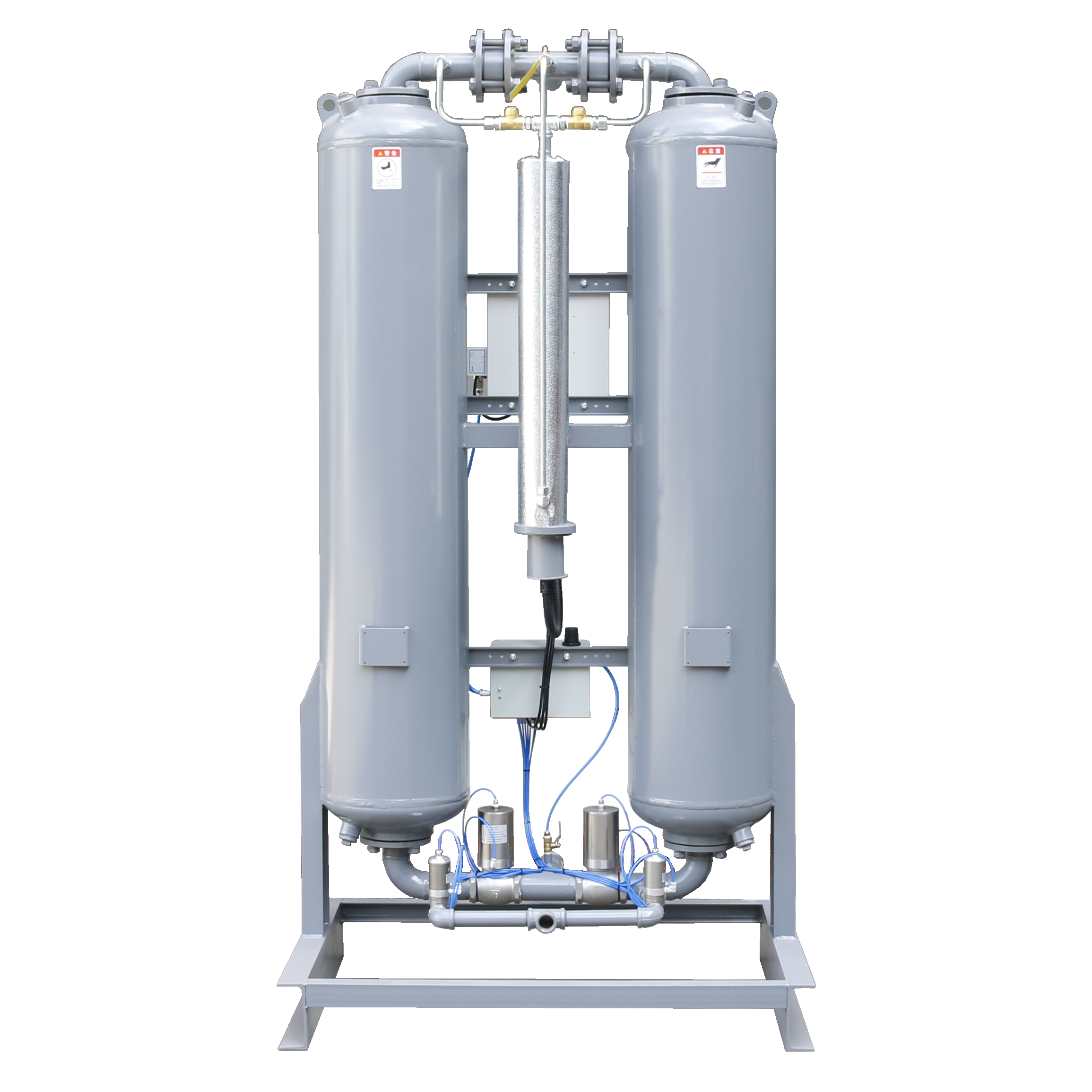

What Is an Air Compressor Desiccant Dryer?

An air compressor desiccant dryer is a moisture removal device that uses adsorption technology to extract water vapor from compressed air. Instead of cooling the air like a refrigerated dryer, it passes compressed air through a desiccant material (typically activated alumina or molecular sieve) that adsorbs moisture molecules.

How It Works:

Compressed air enters the desiccant chamber

Moisture is adsorbed by the desiccant media

Dry air exits with dew points as low as -40°F to -100°F

A secondary chamber regenerates the saturated desiccant for reuse

This two-tower system ensures continuous operation: while one tower dries air, the other regenerates.

Types of Air Compressor Desiccant Dryers

✅ Heatless Desiccant Dryers

Use a portion of the dried air to regenerate the saturated desiccant. Simple and cost-effective.

✅ Heated Desiccant Dryers

Use external electric heaters for regeneration—reducing purge air loss.

✅ Blower Purge Desiccant Dryers

Use ambient air via a blower and heater, making them ideal for energy-conscious facilities.

Why Choose an Air Compressor Desiccant Dryer?

Achieve Ultra-Low Dew Points: Ideal for sensitive applications such as pharmaceuticals, electronics, and painting.

Protect Equipment and Products: Dry air means longer tool life, fewer defects, and less downtime.

Suitable for Cold Climates: Where refrigerated dryers fail, desiccant dryers perform.

Built for Heavy-Duty Use: Designed to withstand high flow rates and continuous operation.

Key Features of Our Air Compressor Desiccant Dryer

| Feature | Description |

|---|---|

| Flow Capacity | 20 – 5000+ CFM (customizable) |

| Pressure Dew Point | -40°F to -100°F |

| Inlet Pressure Range | 4 – 10 bar |

| Inlet Air Temperature | Up to 120°F (option for 150°F) |

| Desiccant Media | Activated Alumina / Molecular Sieve |

| Control System | PLC with LCD Display and Alarm Monitoring |

| Regeneration Type | Heatless / Heated / Blower Purge |

| Certifications | CE / ISO9001 / UL (on request) |

🔧 Maximize Performance — Minimize Downtime

Looking for consistent, ultra-dry air in your production line?

Our air compressor desiccant dryer systems offer:

✅ High-capacity moisture removal

✅ Modular design for easy maintenance

✅ Energy-efficient regeneration cycles

✅ Built-in dew point monitoring

✅ Rugged steel frames for durability

💬 Whether you’re running a food-grade plant or a precision electronics assembly, our dryers deliver dependable performance—even in harsh conditions.

🛠️ Get a Custom Desiccant Dryer Quote

Typical Applications

Our air compressor desiccant dryers are trusted across industries where moisture cannot be tolerated:

🏭 Pharmaceutical Manufacturing – Capsule drying, cleanrooms

🛠 Automotive Paint Shops – Flawless coatings require dry air

🔬 Laboratories and R&D Centers – Precision air for experiments

🧊 Food Processing – Moisture-free packaging environments

⚙️ Industrial Automation – Protect sensors and actuators

🏗 Construction Sites – Cold-weather air tools and equipment

Maintenance Tips

To ensure long-term efficiency:

🔧 Replace desiccant every 12–24 months (based on duty cycle)

🔧 Check filter elements monthly

🔧 Inspect drain valves and pressure gauges regularly

🔧 Calibrate dew point meters semi-annually

🔧 Log cycle count and regeneration status for proactive maintenance

Frequently Asked Questions (FAQ)

What dew point does an air compressor desiccant dryer provide?

Standard models reach -40°F. Optional designs can achieve -100°F for critical applications.

What is the lifespan of the desiccant material?

Typically 1 to 2 years, depending on air quality, flow rate, and maintenance.

Is a pre-filter necessary?

Yes. A high-efficiency pre-filter protects the desiccant from oil, particulates, and water droplets.

How does a desiccant dryer compare to a refrigerated dryer?

Desiccant dryers offer lower dew points and are better for low-temperature or moisture-sensitive applications, whereas refrigerated dryers are suitable for general use.

Can I install it outdoors?

Most units are rated for indoor installation. Weatherproof enclosures can be provided upon request.

Conclusion: Choose the Air Compressor Desiccant Dryer That Works as Hard as You Do

Whether you’re operating in extreme environments, managing precision equipment, or maintaining strict industry standards, a reliable air compressor desiccant dryer is key to productivity.

With ultra-dry air, smart regeneration controls, and long-term durability, our desiccant dryers help you eliminate moisture and maximize uptime.

Don’t settle for “dry enough.” Go ultra-dry—and ensure the success of your compressed air system.

📌 Need a recommendation or help sizing your dryer?

We can help you select the right flow rate, regeneration type, and dew point level for your application.

Related products:

2, Minimum regeneration gas consumption

3. Long service life of adsorbent

4. Easy maintenance

5. High safety

6. High reliability

7.Adjustable regeneration gas consumption

8. Optional dew point monitoring and control system

2. Resists chemical corrosion and extends service life

3. Special sealing technology prevents flammable gases or dust from entering theinterior of the machine

4. Regeneration gas consumption can be adjusted, with energy saving and dewpoint adjustment function

2, Customized high-performance adsorbent, 20% filling margin;

3. Branded high-pressure blower, high-performance pneumatic valve, high-efficiency cooler designed by HTFS software, reliable performance and long life;

4. 304 stainless steel control gas pipeline, specially designed diverter, highadsorbent utilization rate and low gas pressure loss;