Nitrogen generators are valued for their ability to provide a continuous, on-demand supply of nitrogen without the need for storage or regular deliveries of nitrogen gas cylinders.

What is a nitrogen generator?

A nitrogen generator is a device that produces nitrogen gas from the air. It works by using a process called air separation, which involves the following steps:

- Air Intake: The generator draws in ambient air.

- Compression: The air is compressed to a higher pressure.

- Purification:It passes through a purification stage where impurities and water vapor are removed.

- Separation: The purified air is then subjected to a separation process, typically using a Pressure Swing Adsorption (PSA) system or a membrane separation technique. In PSA, the air flows through a bed of adsorbent material that selectively adsorbs oxygen and other nitrogen impurities, leaving behind a concentrated stream of nitrogen.

- Delivery: The purified and concentrated nitrogen gas is then released for use.

Understanding each step of the nitrogen separation process helps in selecting the most efficient nitrogen gas generation system for your specific needs.

How do Lingyu’s PSA nitrogen generators work?

As a trust-worthy nitrogen generator manufacturer, Lingyu provides high-quality nitrogen generators, most of which work through the PSA system.

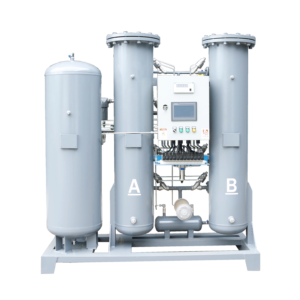

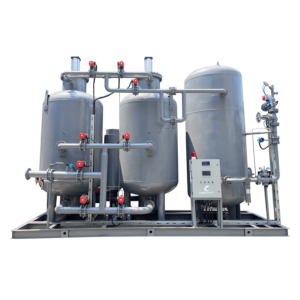

A PSA nitrogen generator is a device that uses two pressure vessels to alternately adsorb oxygen molecules.

- Dual Pressure Vessels: The PSA nitrogen generatorfeatures two pressure vessels, each filled with carbon molecular sieves. These sieves are specialized adsorbents that selectively capture oxygen molecules from compressed air.

- Oxygen Adsorption: Compressed air enters one of the vessels (A tower), where the carbon molecular sieves adsorb oxygen, allowing nitrogen to be collected.

- Regeneration Process: While one vessel (A tower) is engaged in oxygen adsorption, the other vessel (B tower) undergoes a regeneration process. During this phase, a small portion of nitrogen is used to desorb the oxygen molecules from the carbon molecular sieves, which are then released into the atmosphere.

- Automatic Switching:Once the adsorption vessel is saturated, the roles of the vessels switch. The B tower, now saturated, begins the adsorption process while the A tower undergoes regeneration. This seamless transition is managed by PLC controllers, ensuring continuous operation and maintaining high nitrogen purity.

Our PSA nitrogen generators provide consistent performance, making them an ideal choice for various industrial applications.

What are the features of our PSA nitrogen generators?

Lingyu’s PSA nitrogen generators are designed with advanced features to ensure optimal performance and efficiency.

- Automatic stop-open switching for automatic control function

- Pneumatic valve switching automatically controlled by PLC

- Online real-time monitoring of nitrogen purity and flow rate

- Carbon molecular sieve automatic compression

- Digital touch screen to display pressure, purity, and flow rate operating status

- Unequal pressure equalization: This feature increases nitrogen recovery and reduces energy consumption by up to 5%, enhancing overall efficiency

- Unqualified nitrogen alarm: Our generators are equipped with an alarm function that activates if nitrogen quality falls below standards, with an automatic shutdown feature for safety and reliability

Our PSA nitrogen generators combine cutting-edge technology with user-friendly features to deliver reliable and efficient nitrogen generation for your industrial needs. Find and Discover the nitrogen generator that meets your requirements.