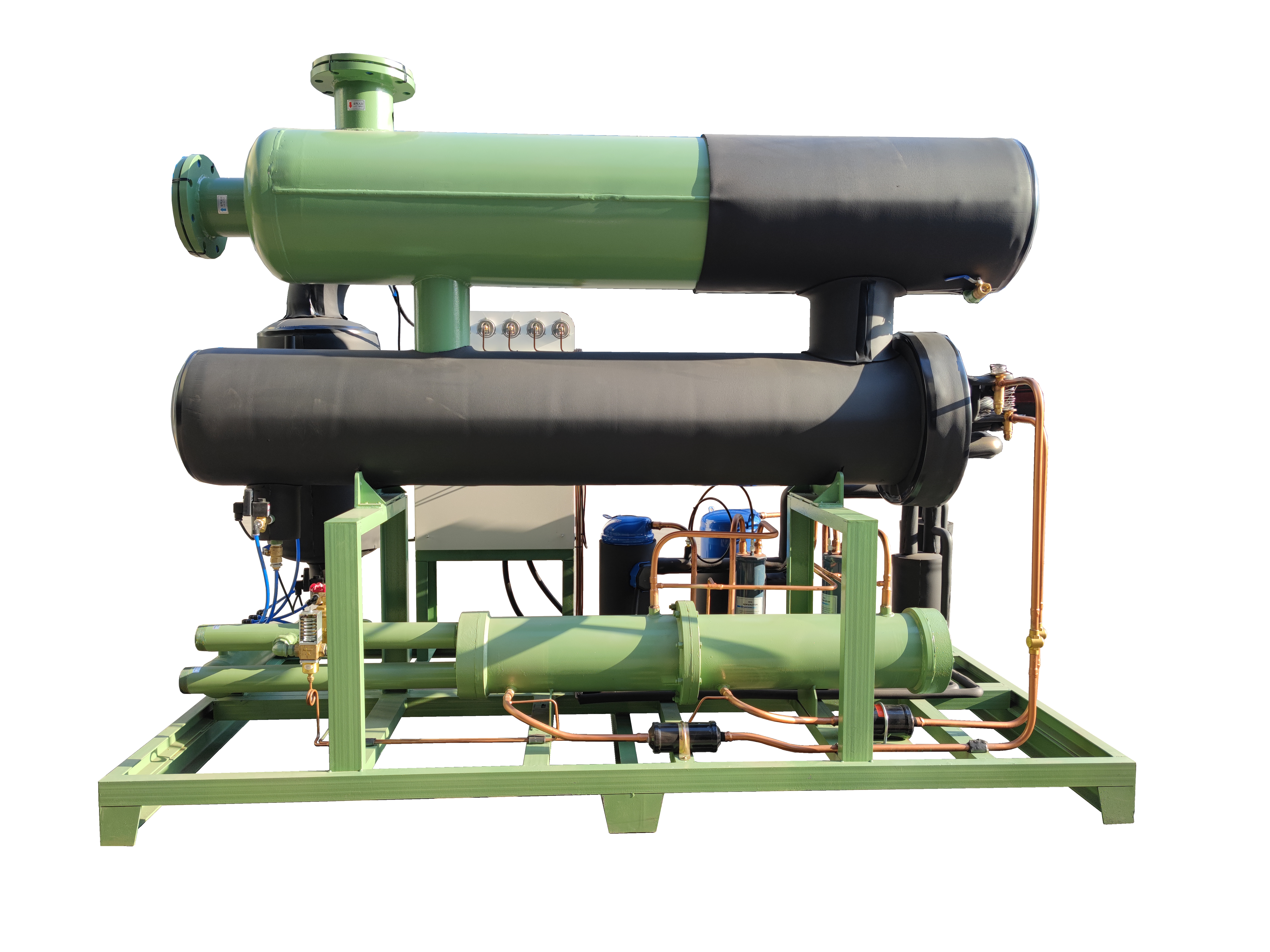

The cycling refrigerated air dryer is an energy-saving solution designed to deliver dry, clean compressed air with maximum efficiency. By cycling the refrigeration compressor on and off in response to compressed air demand, this type of dryer significantly reduces power consumption compared to non-cycling models. The cycling refrigerated air dryer is ideal for industrial applications that require consistent dew point control and reduced operating costs.

Key Features of Cycling Refrigerated Air Dryer

Energy Efficiency:

The cycling refrigerated air dryer minimizes energy usage by operating the refrigeration system only when necessary, saving up to 80% in partial-load conditions.Stable Dew Point:

Maintains a consistent dew point between 2°C and 5°C, ensuring reliable moisture removal for critical applications.Thermal Mass Technology:

Utilizes a thermal mass (such as glycol or water) to store cooling energy and provide consistent performance even when the refrigeration compressor is off.Eco-Friendly Refrigerants:

Uses R134a or R407C refrigerants to meet environmental standards and ensure long-term sustainability.Compact & Durable Design:

The cycling refrigerated air dryer is built with high-quality components, offering a compact footprint and long-lasting performance.

Operating Conditions and Technical Requirements

To ensure optimal operation, the cycling refrigerated air dryer must operate within the following conditions:

| Parameter | Specification |

|---|---|

| Inlet Air Temperature | ≤ 45°C (113°F) |

| Ambient Temperature | 5°C – 45°C (41°F – 113°F) |

| Working Pressure | 4 – 10 bar (0.4 – 1.0 MPa) |

| Dew Point | +2°C ~ +5°C |

| Cooling Method | Air-cooled or Water-cooled |

| Power Supply | 220V/1Ph/50Hz or 380V/3Ph/50Hz |

| Refrigerant | R134a / R407C |

The cycling refrigerated air dryer is engineered for high reliability under these typical working conditions.

Technical Specifications (Sample Models)

| Model | Flow Rate (CFM) | Power (kW) | Connection Size | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|

| LY-100 | 100 | 0.7 | DN25 | 800 × 600 × 950 | 70 |

| LY-300 | 300 | 1.8 | DN40 | 1000 × 750 × 1200 | 120 |

| LY-800 | 800 | 3.5 | DN65 | 1300 × 900 × 1400 | 210 |

| LY-1500 | 1500 | 6.0 | DN100 | 1600 × 1100 × 1600 | 350 |

| LY-3000 | 3000 | 11.0 | DN150 | 1800 × 1200 × 1800 | 550 |

Customized sizes and higher flow capacities are available for your specific cycling refrigerated air dryer requirements.

Application Scenarios

The cycling refrigerated air dryer is suitable for a wide range of industrial applications where energy efficiency and air quality are critical:

Automotive Workshops: Protects tools and equipment by supplying dry compressed air.

Food & Beverage Industry: Maintains hygiene by preventing moisture contamination.

Pharmaceutical Manufacturing: Ensures product integrity through dry, clean air.

Textile & Printing: Prevents moisture-related defects in fabrics and printed materials.

CNC Machining & Assembly Lines: Enhances accuracy and extends equipment lifespan.

In all these environments, the cycling refrigerated air dryer provides stable dew point control and energy savings.

Frequently Asked Questions (FAQ)

What is the main benefit of a cycling refrigerated air dryer?

The primary benefit is energy savings. A cycling refrigerated air dryer only operates the refrigeration compressor when needed, reducing electricity costs without compromising performance.

Is a cycling refrigerated air dryer suitable for continuous operation?

Yes. The cycling refrigerated air dryer is designed for continuous use and automatically adjusts its operation to air demand.

How often does the dryer need maintenance?

Maintenance is minimal. Regular filter replacements and periodic inspections will ensure your cycling refrigerated air dryer performs reliably.

Can I use this dryer with any air compressor?

Yes. The cycling refrigerated air dryer is compatible with most compressed air systems, provided flow rate and pressure requirements match.

What is the expected lifespan?

With proper maintenance, a cycling refrigerated air dryer can last 8–12 years or more.

Why Choose Our Cycling Refrigerated Air Dryer?

✔ Over 15 years of manufacturing experience

✔ Exported to over 40 countries worldwide

✔ Advanced thermal mass and control systems

✔ Professional after-sales and technical support

✔ Custom solutions available for all industries

Get a Quote Now

Need a reliable and efficient cycling refrigerated air dryer for your system? Contact us today for technical consultation, datasheets, or a customized solution. Our experts will help you choose the perfect model for your air treatment needs.

Related products:

The 3885 CFM refrigerated air dryer (water cooled) is a high-capacity industrial solution designed for removing moisture from large-scale compressed air systems. Built for continuous and demanding operation, this water-cooled unit ensures a steady dew point and maximum system protection. Whether you're operating in petrochemical, steel, manufacturing, or pharmaceutical industries, the 3885 CFM refrigerated air dryer delivers superior drying performance and energy efficiency.

The 4238 CFM refrigerated air dryer (water cooled) is a high-capacity, industrial-grade dryer designed to eliminate moisture from large compressed air systems. Built with a powerful water-cooled refrigeration circuit, this dryer ensures reliable and continuous moisture removal with a stable pressure dew point. For industries that demand high airflow rates and dependable air quality, the 4238 CFM refrigerated air dryer (water cooled) is the ideal solution.

The 8830 CFM refrigerated air dryer (water cooled) is a top-tier industrial solution engineered to remove moisture from large-scale compressed air systems. Built for ultra-high capacity applications, this dryer ensures consistently dry air with a stable dew point and superior thermal control using an advanced water-cooled condenser system.