At Lingyu, we are dedicated to providing advanced solutions for gas generation, specializing in PSA pressure swing adsorption nitrogen generators. Our systems are designed to meet the growing demand for high-purity nitrogen across various industries. By understanding our technology and its benefits, you can see why we are a trusted partner in nitrogen generation.

Table of Contents

ToggleHow the PSA Nitrogen Generator Works

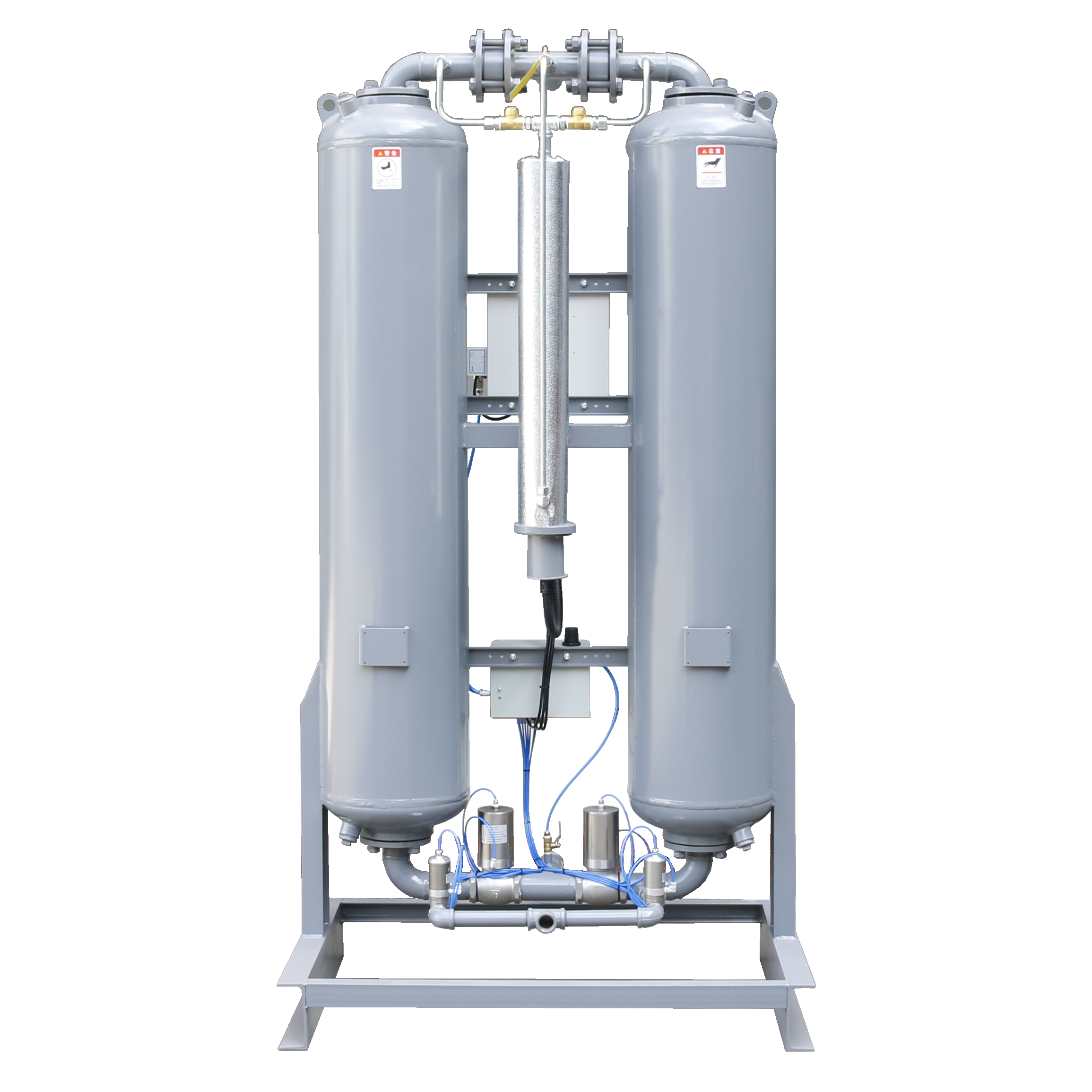

The PSA pressure swing adsorption nitrogen generator consists of two pressure vessels that alternately switch to adsorb oxygen molecules. Each container is filled with carbon molecular sieves, which are specifically designed to adsorb oxygen while allowing nitrogen to pass through.

When compressed air enters one of the A towers, the oxygen is adsorbed by the carbon molecular sieve, and the nitrogen is collected for use. During this process, the other B tower undergoes a regeneration and decoupling action, where the oxygen molecules are released back into the atmosphere using a small amount of energy. This cycle continues, allowing for continuous nitrogen production.

The automatic switching between the two towers is managed by a PLC controller, ensuring optimal purity and efficiency. This sophisticated design allows us to provide a reliable nitrogen generator that meets the specific needs of our customers.

Benefits of Our Nitrogen Generators

Cost-Effective Solution

Investing in a nitrogen generator from Lingyu offers significant cost savings for businesses. By generating nitrogen on-site, companies can eliminate the need for expensive gas cylinders or bulk deliveries. This not only reduces operational costs but also minimizes the time and resources spent on logistics.

High Purity and Reliability

Our PSA nitrogen generators are engineered to produce high-purity nitrogen consistently. With the ability to achieve purities of up to 99.999%, businesses can rely on our systems to meet the stringent requirements of various applications, including food packaging, pharmaceuticals, and electronics.

Moreover, the automatic switching mechanism ensures that even during regeneration, the purity levels remain stable, providing peace of mind for our clients.

Environmentally Friendly

By utilizing a nitrogen generator, companies can significantly reduce their environmental footprint. On-site generation minimizes the carbon emissions associated with transporting and storing nitrogen gas. Additionally, our systems are designed for energy efficiency, further contributing to sustainability efforts.

Applications of Lingyu Nitrogen Generators

Our nitrogen generators are versatile and applicable across multiple industries. In the food and beverage sector, they are used for packaging to prevent oxidation and extend shelf life. In pharmaceuticals, our generators create inert atmospheres that protect sensitive compounds during production.

Additionally, the electronics industry benefits from our nitrogen generators to ensure a contamination-free environment, while metal fabrication processes utilize nitrogen to enhance the quality of welds and cuts.

Conclusion:

At Lingyu, we are more than just a manufacturer; we are your partner in achieving operational excellence through our advanced nitrogen generator technology. Our PSA pressure swing adsorption systems provide a reliable, cost-effective, and environmentally friendly source of high-purity nitrogen tailored to your specific needs. We invite you to explore our innovative solutions and experience the difference that Lingyu can make for your business. Together, we can drive efficiency and sustainability in your operations.