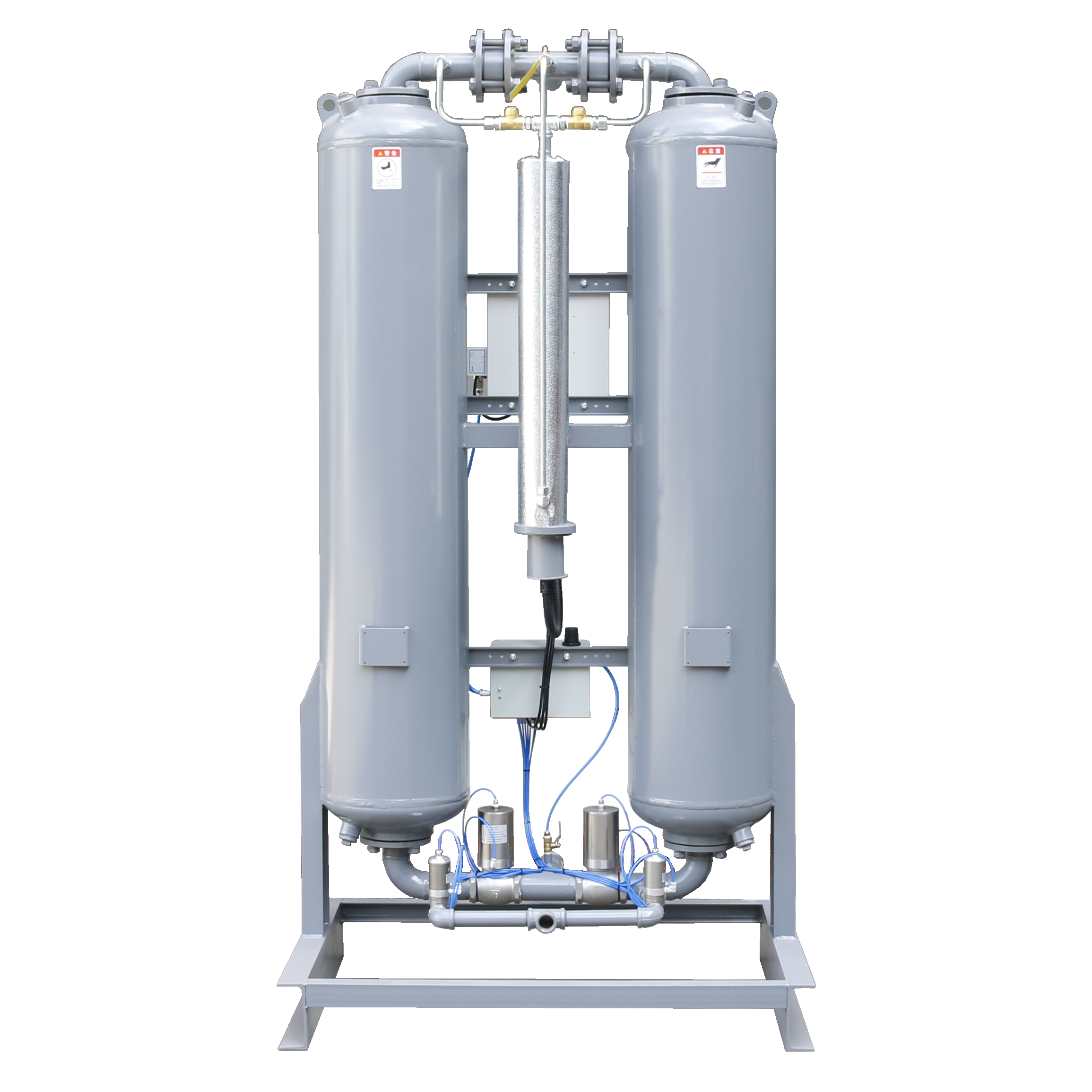

We would like to take this opportunity to welcome you to Lingyu, where we find excellence in industrial drying solutions. The cutting-edge 3-in-1 plate heat exchange refrigerated air dryer that we have developed is designed to revolutionize the way industrial operations are conducted in terms of both efficiency and sustainability. This dryer represents a significant step forward in technology because it focuses on minimizing pressure drop and reducing energy consumption. As a result, it offers businesses a solution that is both dependable and cost-effective for meeting their drying requirements.

The Design of Energy-Efficient Products for Exceptional Performance

In the highly competitive industrial environment of today, energy efficiency is of the utmost importance. This is something that was taken into consideration when Lingyu designed their 3-in-1 plate heat exchange refrigerated air dryer. This dryer is able to achieve remarkable energy savings of 20-30% when compared to conventional models because it incorporates a plate heat exchanger that consists of three interchangeable plates. Not only does this lower operational costs, but it also aligns with sustainable practices, which makes it an environmentally conscious choice for businesses that are looking to reduce their carbon footprint.

Minimizing Pressure Drop for Seamless Operation

Pressure drop can significantly impact the performance of refrigerated air dryers. Lingyu’s 3-in-1 plate heat exchange dryer addresses this challenge by maintaining a pressure loss of less than 0.015MPa across the entire machine. This low pressure drop ensures smooth and uninterrupted operation, allowing businesses to maintain consistent air quality without disruptions, thereby enhancing overall productivity.

Enhancement of Productivity with the help of cutting-edge technology

Lingyu’s 3-in-1 plate heat exchange refrigerated air dryer incorporates cutting-edge technology to enhance its performance, in addition to its energy-saving and pressure-reducing capabilities. The incorporation of a plate heat exchanger makes it possible to transfer heat in an effective manner, which guarantees that moisture is effectively removed from the compressed air stream. Because of this, the air that is produced is dry and clean, and it satisfies the stringent quality requirements of a variety of industrial applications.

Conclusion:

Lingyu’s 3-in-1 plate heat exchange refrigerated air dryer stands as a testament to our commitment to providing high-quality, sustainable solutions for industrial drying needs. By choosing Lingyu, businesses can benefit from enhanced efficiency, reduced operational costs, and improved productivity. Our dryer not only meets the demands of today’s industrial landscape but also contributes to a greener, more sustainable future.