In large-scale manufacturing, compressed air is an indispensable energy source. However, the moisture contained in the air can have adverse effects on the production process, so it is crucial to remove water and dry the compressed air. Among them, adsorption dryers have become the first choice of many large manufacturing companies because of their high efficiency and energy saving characteristics. So, how do you select and deploy this equipment?

Consideration of environmental conditions is critical in selecting and deploying an sorption compressed air dryer.

Equipment usage conditions: When large manufacturing companies determine the model and capacity of adsorption dryers, they need to consider the impact of environmental temperature, humidity and other factors inside and outside the factory on equipment performance. High temperature and high humidity environments will affect the performance of the dryer and may even cause the equipment to operate abnormally or reduce drying efficiency. Therefore, when selecting and deploying an adsorption dryer, it is necessary to fully understand and evaluate the environmental conditions of the factory to ensure that the purchased equipment can operate normally and efficiently in the specific environment. Choosing the right model and capacity is critical for large manufacturing companies.

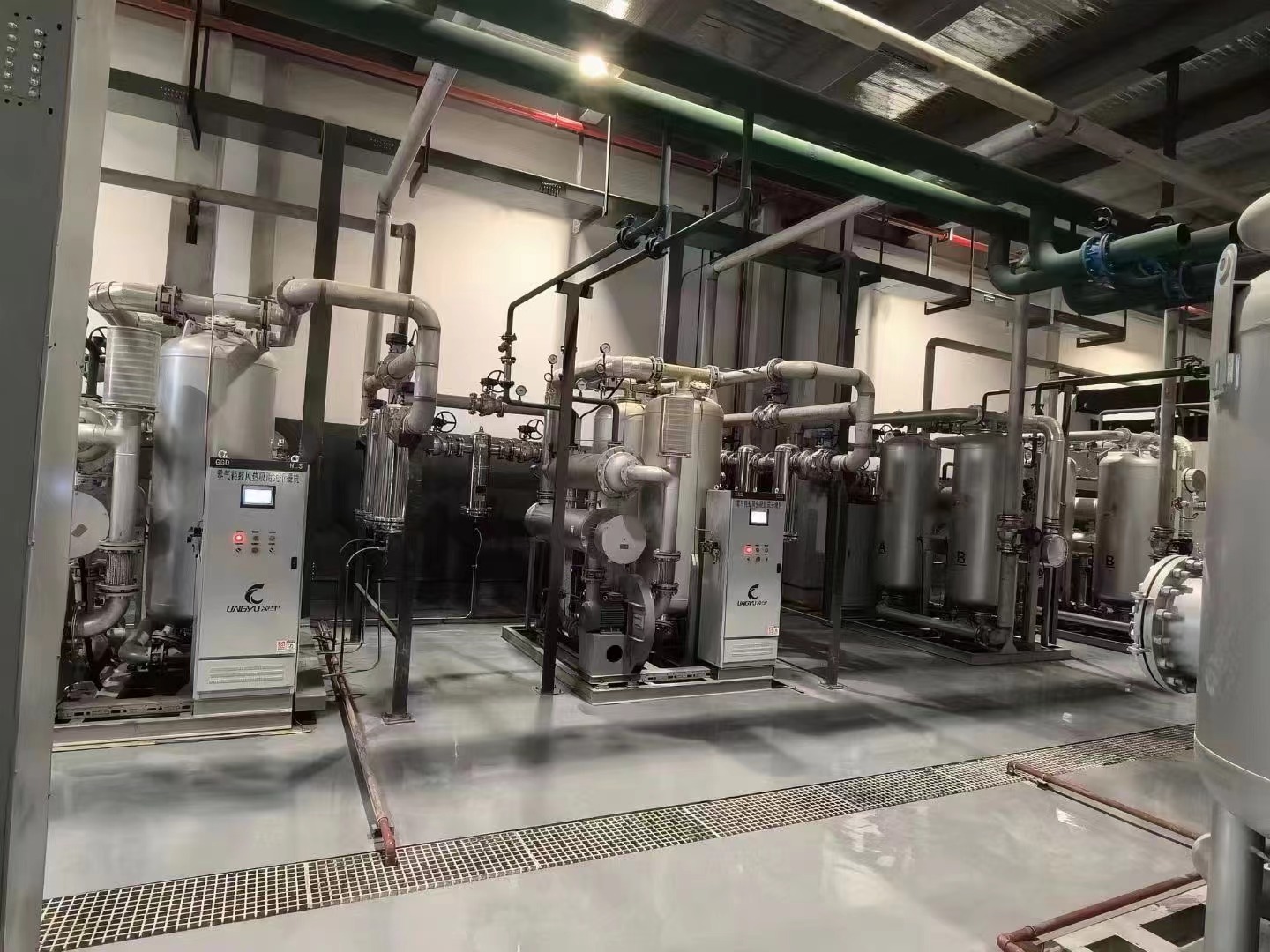

Compressed air demand: On the basis of determining the demand, companies need to consider factors such as production scale, air quality standards, and production environment to select an adsorption dryer with appropriate air quality and processing capacity. If the processing capacity of the adsorption dryer is too small, it will not be able to meet the needs of the factory, thus affecting production efficiency; while if it is too large, it will cause a waste of energy. Therefore, accurate calculation and selection of appropriate air quality and processing capacity are key steps to ensure compressed air drying effect and energy-saving operation.

Consider energy efficiency: Energy efficiency is a crucial consideration when selecting an adsorption dryer. High energy efficiency adsorption dryers can effectively reduce energy consumption and reduce business operating costs. Therefore, when purchasing dryers, manufacturing companies should focus on the energy utilization of the equipment. Especially if the gas consumption is large, choosing products with advanced energy-saving technology will save a lot of compressed air gas costs. By investigating and comparing the energy consumption data of different brands and models of dryers in advance, manufacturing companies can make informed decisions and select equipment that best meets their needs and optimizes energy efficiency.

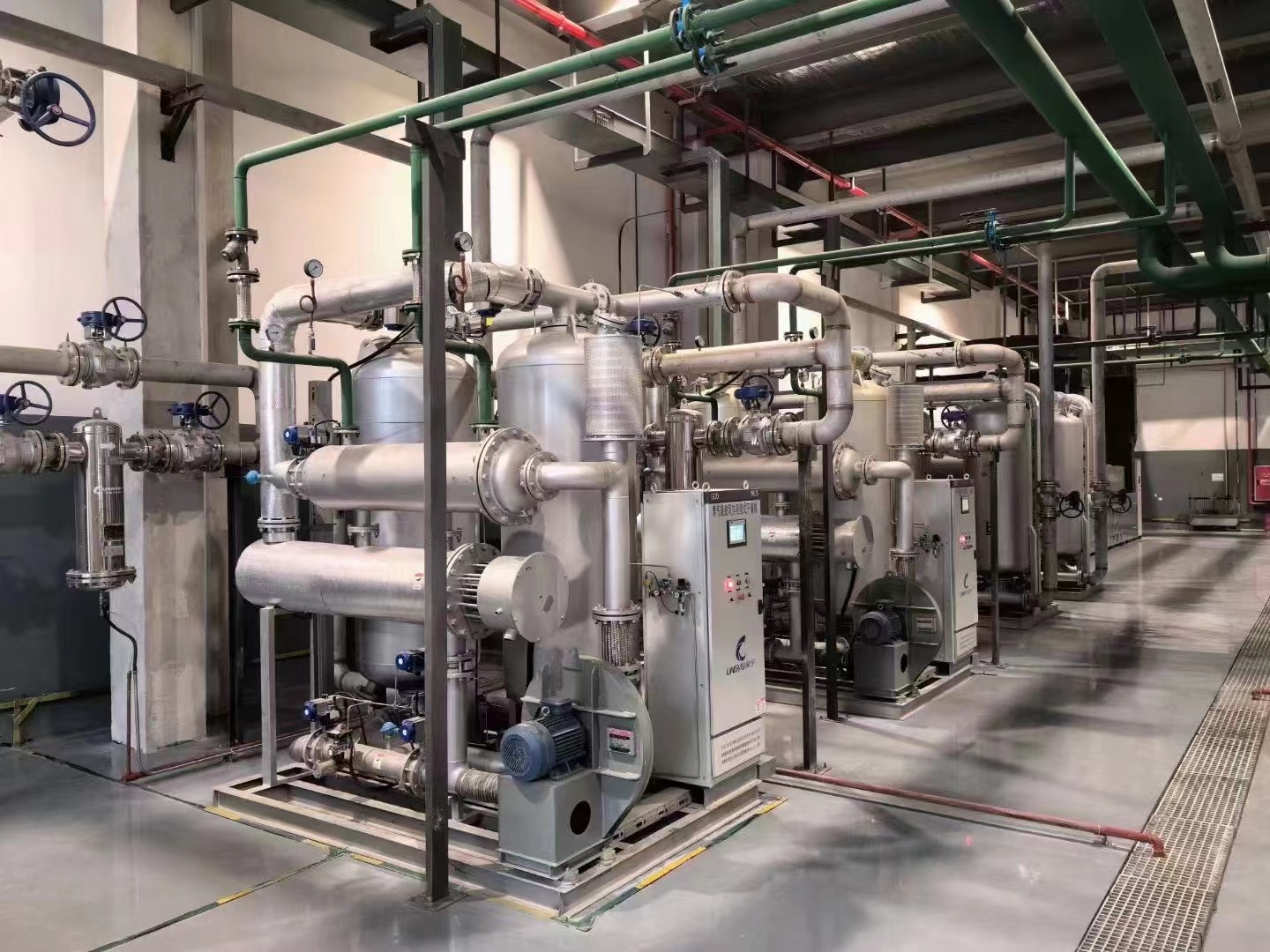

Installation and debugging: When installing an adsorption dryer, you should first place the equipment reasonably according to the factory structure and space, and ensure good ventilation to avoid any blockage. Secondly, when connecting the air inlet and outlet pipes, carefully check the sealing to ensure there is no air leakage. The debugging phase needs to be set accordingly according to production needs and dryer parameters to ensure that the working parameters achieve the best results. Finally, durability testing and quality verification are performed to ensure the stable operation and efficient working of the adsorption dryer.

Enterprises need to focus on the maintenance of equipment. First of all, make sure to regularly clean and replace wearing parts such as filter elements and screens to prevent dust and impurities from clogging the machine and affecting normal operation. Secondly, develop a maintenance plan and regularly inspect and maintain the adsorption dryer to ensure that the equipment is in optimal condition. In addition, employees are trained to master correct operating methods and maintenance skills to improve the efficiency of equipment and extend its service life. Finally, establish a good cooperative relationship with suppliers, conduct regular equipment testing and maintenance, and handle equipment failures in a timely manner to ensure that production is not affected.