Enter the world of precision engineering with Lingyu, where state-of-the-art technology and unmatched knowledge of industrial gas solutions come together. At Lingyu, we are proud to introduce our latest innovation in gas generation technology – the PSA (Pressure Swing Adsorption) Nitrogen Generators. Designed to meet the exacting demands of modern industries, our nitrogen generators offer a seamless and efficient solution for producing high-purity nitrogen gas. Join us on a journey to discover how Lingyu’s PSA Nitrogen Generators are transforming the landscape of industrial gas generation, setting new standards for performance and reliability.

Unveiling the Technology Behind PSA Nitrogen Generators

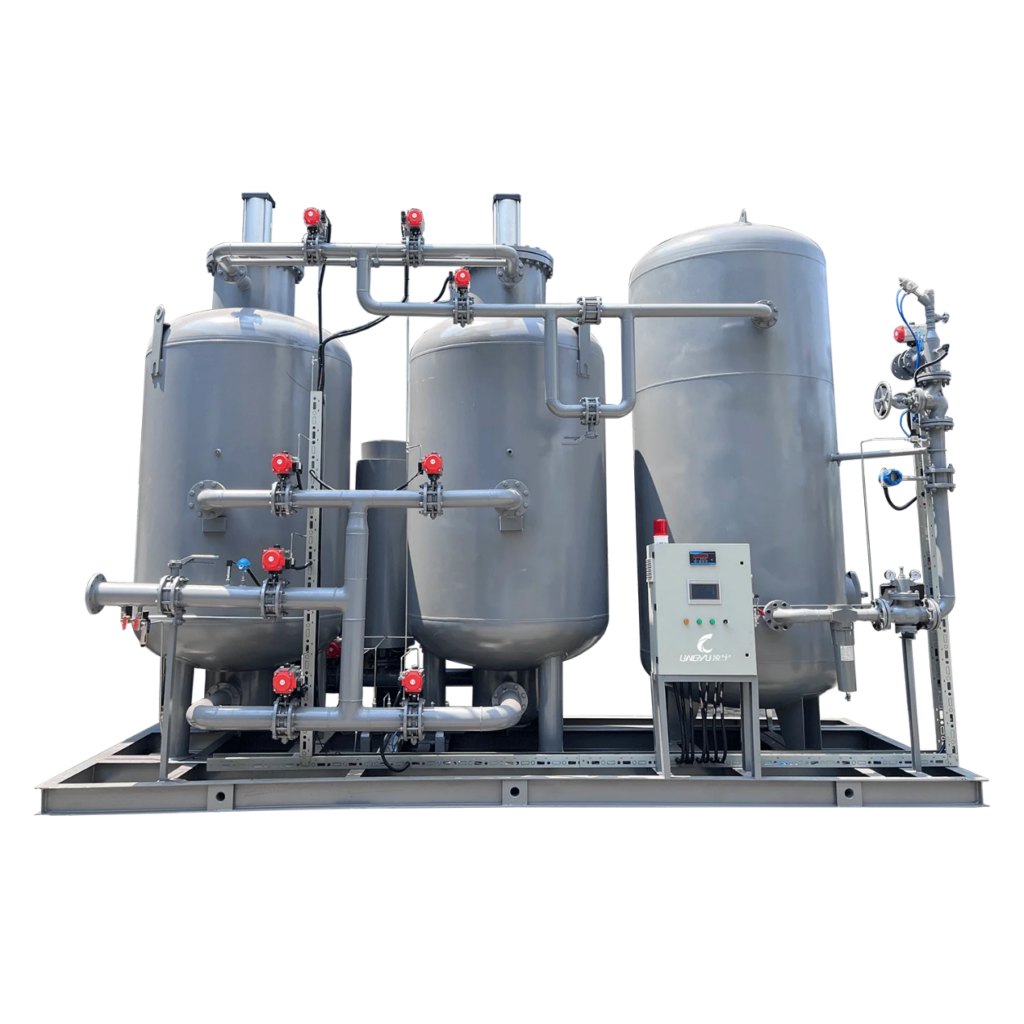

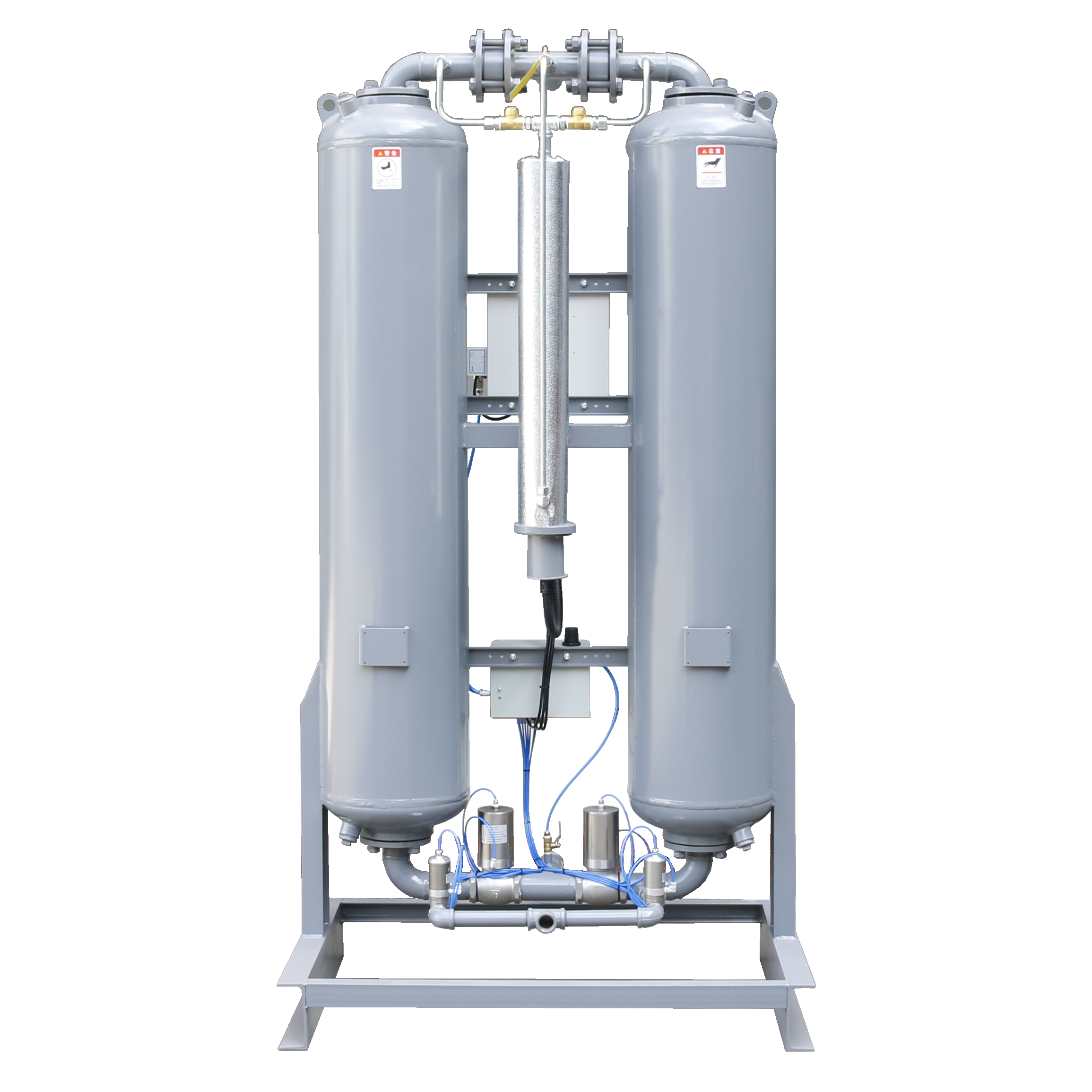

PSA Nitrogen Generators are at the forefront of industrial gas generation technology, offering a reliable and efficient solution for producing high-purity nitrogen gas. At Lingyu, our generators consist of two pressure vessels that operate in an alternating manner to adsorb oxygen molecules from compressed air. These vessels are filled with specialized carbon molecular sieves that have a high affinity for oxygen adsorption while allowing nitrogen to pass through.

The operation of Lingyu’s PSA Nitrogen Generators involves the compressed air entering one of the vessels, where oxygen is adsorbed by the carbon molecular sieve, allowing pure nitrogen to be collected. Simultaneously, the other vessel undergoes regeneration and desorption, releasing the adsorbed oxygen molecules along with a small amount of nitrogen back into the atmosphere. This cyclic process ensures a continuous supply of high-purity nitrogen gas for industrial applications.

Enhancing Efficiency and Purity with PSA Nitrogen Generators

The key advantage of Lingyu’s PSA Nitrogen Generators lies in their ability to maintain consistent purity levels through precise control and automation. Using a PLC (Programmable Logic Controller) system, the two pressure vessels automatically switch between adsorption and regeneration phases to ensure a continuous supply of pure nitrogen gas. This automated process optimizes efficiency, minimizes downtime, and guarantees a reliable output of nitrogen gas tailored to the specific requirements of industrial processes.

By incorporating advanced technology and intelligent control mechanisms, Lingyu’s PSA Nitrogen Generators offer unparalleled efficiency and purity in nitrogen generation. Businesses can rely on our generators to deliver a steady and high-quality nitrogen gas supply, meeting the stringent demands of various industrial applications with precision and reliability.

Why Choose Lingyu’s PSA Nitrogen Generators

When it comes to selecting nitrogen generation solutions for industrial applications, Lingyu’s PSA Nitrogen Generators stand out as the ideal choice for businesses seeking unmatched performance and reliability. Our generators are designed based on the principle of pressure swing adsorption, ensuring the efficient separation of oxygen and nitrogen to produce high-purity nitrogen gas.

By choosing Lingyu’s PSA Nitrogen Generators, businesses can benefit from advanced technology, superior purity levels, and seamless operation. With a focus on innovation and quality, Lingyu delivers nitrogen generation solutions that optimize industrial processes, reduce operational costs, and enhance overall efficiency.

Conclusion:

In conclusion, Lingyu’s PSA Nitrogen Generators represent a pinnacle of innovation and efficiency in industrial gas generation technology. By leveraging the principles of pressure swing adsorption, our generators ensure a continuous supply of high-purity nitrogen gas tailored to the specific needs of diverse industries. Choose Lingyu for industry-leading PSA Nitrogen Generators that elevate performance, purity, and reliability in industrial gas applications. Experience the difference with Lingyu – where precision meets innovation to redefine nitrogen generation for businesses worldwide.