Compressed air serves as a power tool for equipment, tools, and processes in most of our industries. However, the air that compressors generate contains water vapor (moisture). This moisture can damage our pneumatic equipment and contaminate products by causing corrosion.

Refrigerated air dryers for air compressors solve this issue and keep the air dry and clean. This keeps our operations running smoothly and efficiently. Now, let’s take a closer look at the refrigerated air dryer for air compressors and uncover its benefits across a number of industries.

Table of Contents

ToggleUnderstanding Refrigerated Air Dryers for Air Compressors

A refrigerated dryer is a device used in industry settings to remove moisture from the compressed air so as to maintain air quality, prevent corrosion, and protect machinery from damage. The Refrigerated air dryers for air compressors work by cooling the air to around 3°C (37°F). It results in water vapors present in the compressed air condensing into the liquid form. This liquid then drains out, leaving the air dry.

Key components of a refrigerated air dryer include:

- Compressor: As the core component, it compresses low-pressure refrigerant gas into high-pressure gas and powers the refrigeration cycle, which is essential for cooling the air.

- Heat Exchanger: It transfers heat from the incoming warm air to the outgoing cold air, improving energy efficiency.

- Separator: This component is responsible for removing condensed water from the cooled air.

- Refrigerant: It is a substance in a closed loop that absorbs and releases heat as it cycles between liquid and gas states, cooling the air.

Benefits of Using Refrigerated Air Dryers for Air Compressors

Refrigerated air dryers for air compressors have many benefits. Here are its three key benefits in industrial operations.

Moisture Removal

Moisture in compressed air may cause corrosion, freeze in colder climates, and encourage bacterial growth, therefore affecting industrial operations. The function of a compressed air dryer system is to cool the air, condense the moisture, and drain it away. It makes sure that only dry air is used. This process not only protects equipment but also prevents contamination in sensitive industries like food processing and pharmaceuticals.

Reduced Downtime and Maintenance

Refrigerated air dryers for air compressors help protect components from rust and wear by removing moisture. Ultimately, the life of our equipment is extended. It also reduces maintenance needs. For many businesses, this improvement in operational efficiency lowers overall costs.

Enhanced Product Quality

Dry air is required in many applications where moisture could compromise the quality of the final product. For example, in painting and coating applications, dry air gives us a smooth finish without blisters or bubbles caused by trapped moisture. We can get consistent and high-quality results with refrigeration air dryers.

Lingyu: A Trusted Name in Refrigerated Air Dryers for Air Compressors

When we are out there looking for a reliable industrial air dryer for a compressor, choosing the right one is often challenging. Among all the options out there, Lingyu serves as a reliable manufacturer of high-quality air compressors and refrigerated air dryers. With years of experience in the industry, we have built a strong reputation for delivering durable and efficient refrigerated air dryers tailored to meet the diverse needs of our clients.

With a commitment to excellence, we ensure that our products not only perform exceptionally but also stand the test of time, making us a trustworthy partner for your compressed air requirements. Here are two of our outstanding refrigerated air dryers:

3 In 1 Plate Heat Exchange Refrigerated Air Dryer

Our 3 In 1 Plate Heat Exchange Refrigerated Air Dryer is designed to provide optimal moisture removal. It comes with excellent energy efficiency. Its features and applications are as follows:

Features:

- Energy Efficient: This refrigerated air dryer for air compressors operates on an advanced plate technology to maximize heat transfer. With the plate heat exchanger, it gives rapid cooling of compressed air and reduces 20%–30% of energy consumption.

- Durable and stable: With the dew point as low as 2° to 10°, it adopts an electronic bypass valve to ensure stable operation of the systems.

- Environmentally friendly: This system uses refrigerants R410A/R407C, compliant with international environmental standards.

- Compact Design: Its space-saving structure makes it ideal for installations with limited space.

Applications:

- Manufacturing Plants

- Automotive Workshops

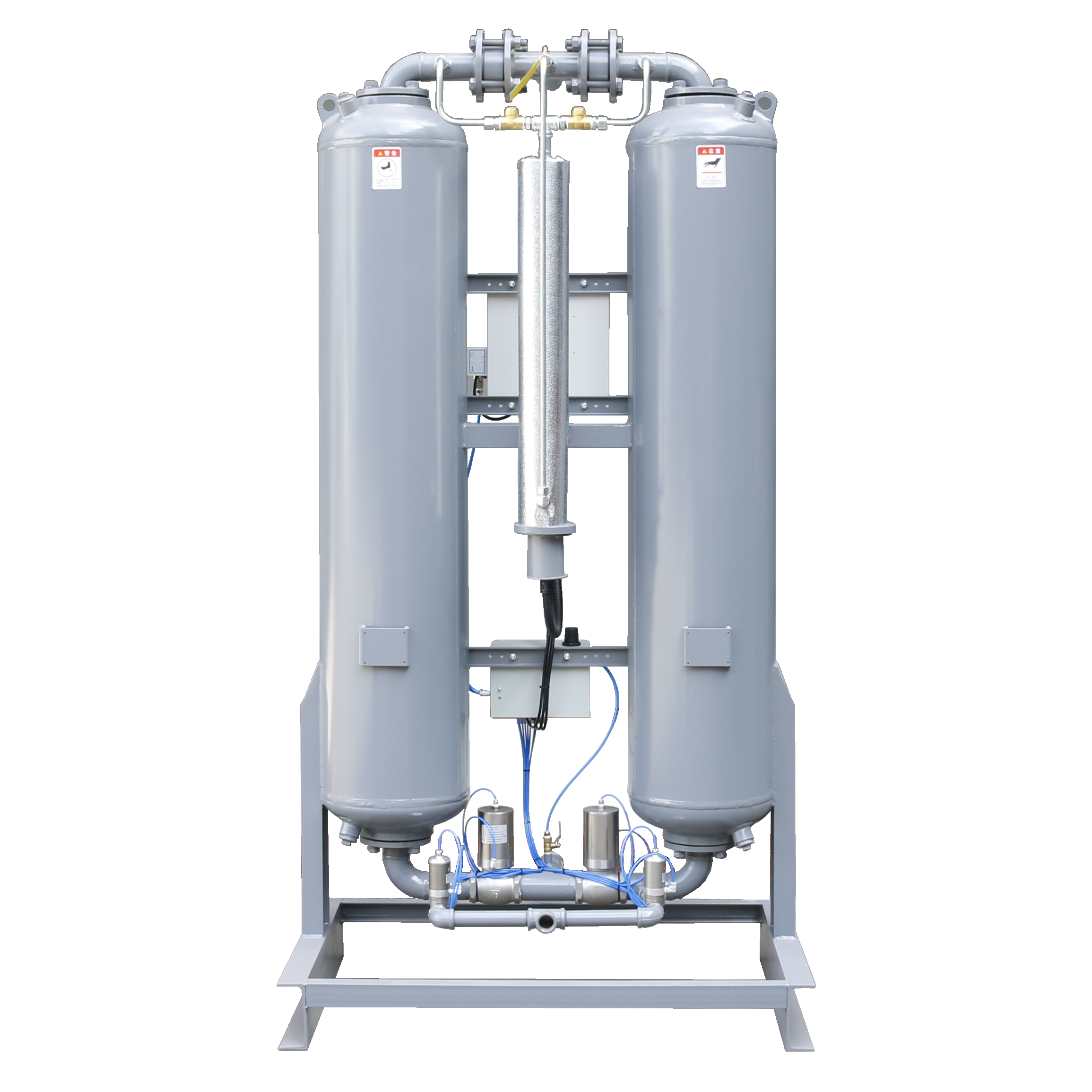

110m³ Water-Cooled High-Temperature Refrigerated Dryer

The 110m³ Water-Cooled High-Temperature Refrigerated Dryer is engineered to handle high-capacity air systems. It delivers superior performance even in demanding environments.

Features:

- Water-Cooled System: It utilizes water as a cooling medium and provides efficient temperature control for large-scale operations.

- High-Temperature Capability: We have designed it specifically to operate effectively with high-temperature compressed air. This makes it suitable for environments where air temperatures exceed standard levels.

- Intelligent Dual Systems: With a dual-compressor design, this refrigerated air dryer for air compressors is more energy-saving and suitable for scenarios with large gas fluctuations.

- Customizable Design: Its color, PLC, dry contacts, and Modbus communication can be tailored to meet customer needs.

Applications:

- Heavy Industrial Facilities

- Petrochemical Industries

- Power Generation Plants

Common Issues Troubleshooting

We often see some common issues that come with refrigerated air dryers. Here is how you can resolve these issues:

- High-Pressure Drop: Blockages in components like filters or heat exchangers may lead to a high-pressure drop in the refrigerated air dryers. Dirty or clogged filters and heat exchangers restrict airflow. It causes the system to overwork. To solve this, simply clean filters and heat exchangers regularly.

- Poor Moisture Removal: If your dryer is not removing moisture effectively, you can check the condensate drain valve, as blockages in this valve are common. Additionally, it may stem from refrigerant issue leaks or inadequate temperature control. To address this issue, we should clean or replace filters regularly. Also, we should ensure the refrigerant circuit operates within the correct temperature range to maintain optimal dew point control.

- Refrigerant Leaks: Refrigerant leaks cause severe damage to the cooling cycle and moisture removal efficiency. You can conduct a soap bubble test on joints and connections in the refrigeration circuit to detect leaks. If you detect a leak, we advise that you should contact a certified technician for repairs because refrigerant handling requires specific expertise.

Conclusion

Refrigerated air dryers are important devices for maintaining clean and dry air in compressed air systems. They reduce equipment wear and maintain product quality. Lingyu has been an industry expert in air treatment for more than a decade. We offer a complete range of refrigerated air dryers for air compressors. Want to know more about how Lingyu can help your specific industry needs for refrigeration air dryers? Get in touch with us and explore our product portfolio today!