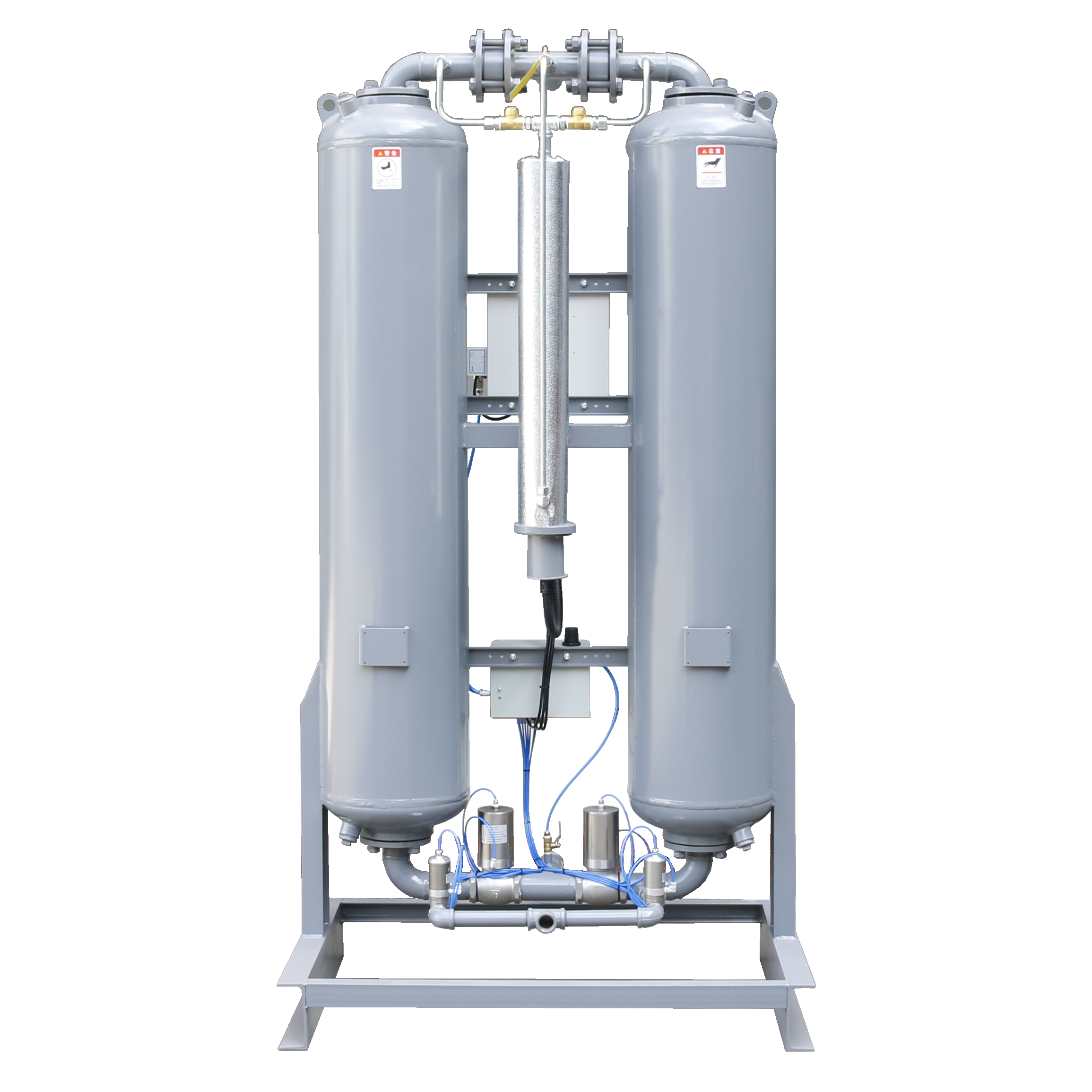

When it comes to maintaining the integrity of compressed air systems, Lingyu recognizes that an air compressor dryer is a vital component. Moisture is a byproduct of air compressor operation, and if left unchecked, it can contaminate end products and cause significant damage to production equipment. This is precisely why it is essential to remove moisture from the compressor system. Compressed air dryers are the devices that effectively dry wet air, ensuring the quality of your compressed air. But how do you determine the best air dryer for your air compressor? Let’s explore some key considerations.

Table of Contents

ToggleUnderstanding Aicr Capacity

Choosing the right air dryer begins with understanding air capacity, which signifies the maximum flow of compressed air that the dryer can manage. Users should evaluate the consumption rates of all air-consuming equipment and factor in usage. If you have an existing air compressor, consult the nameplate for pertinent details.

As an air dryer manufacturer, we emphasize the importance of selecting a dryer with a capacity larger than that of the air compressor, especially if your system requires a significant volume of air. During high temperature and humidity conditions, the water content in the air increases, which can overload the dryer. This overload leads to diminished drying effectiveness, resulting in increased moisture and potential equipment issues.

Evaluating Inlet Air Pressure

Another critical factor is the inlet air pressure. Different pressures result in varying air capacities of the dryer. In most industrial settings, common pressures range from 0.6 MPa to 1.0 MPa, making normal pressure air compressor dryers the standard choice.

Importance of Temperature Considerations

Temperature plays a significant role in selecting an air compressor dryer. Refrigerated air dryers come in two types: normal temperature (up to 50°C) and high temperature (up to 80°C). In regions with high summer temperatures, such as Pakistan and the Middle East, it’s critical to choose a high-temperature refrigerant dryer. It’s often beneficial to select a larger model to achieve effective moisture removal and minimize downtime.

Conclusion

To sum up, selecting the appropriate air compressor dryer requires careful consideration of air capacity, inlet air pressure, and temperature conditions. At Lingyu, we pride ourselves on being a dedicated air dryer manufacturer, providing tailored solutions that meet your specific needs. By investing in the right air dryer, you can enhance your production efficiency and protect your equipment, ensuring a reliable and productive operation.