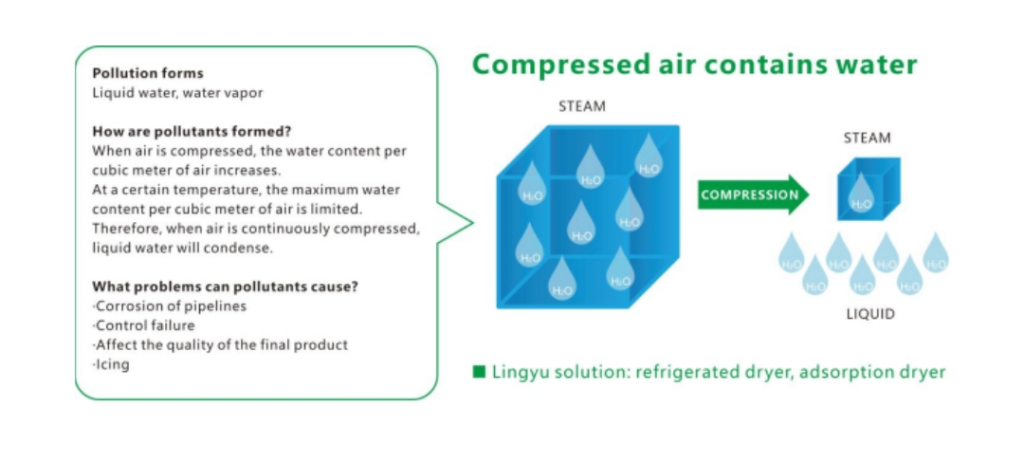

Atmospheric air in any residential or industrial setting contains water vapors. Now, consider these settings as sponges that retain moisture. When we squeeze the sponge, there will be excess water. The same thing happens when air is quickly pressurized. That’s why the adsorption dryer is so essential to achieve compressed dry air. It protects from potential problems like shutdowns and increased maintenance costs.

Moreover, water vapor in the air contains microorganisms and corrosive elements. These factors affect compromise production quality, damage equipment, and reduce system efficiency. To address these challenges, adsorption dryers play a key role in achieving clean, dry air while enhancing energy efficiency. Let’s find out how adsorption dryers help in achieving clean, dry air and the practical applications of five main types of energy-efficient adsorption dryers.

Table of Contents

ToggleOverview of Adsorption Dryers

An adsorption dryer is a device that uses an adsorption process to remove water vapors from compressed air. These dryers rely on desiccant materials such as activated alumina or silica gel to remove moisture from compressed air.

Adsorption Principle:

When compressed air comes into contact with the adsorbent, the water molecules in the compressed air diffuse onto the surface of the adsorbent and are adsorbed due to Van Der Waals forces and the porous structure of the adsorbent.

Regeneration Principle:

The water vapor adsorbed on the surface can be removed by heating the adsorbent, changing the pressure, or purging with compressed air, which is known as desorption.

There are five primary types of adsorption dryers. Each type has unique energy-saving features and applications:

- Heatless Regeneration Adsorption Dryer

- Heated Regenerative Adsorption Dryer

- Blower Heated Adsorption Dryer

- Compression Heated Adsorption Dryer

- Modular Heatless Adsorption Dryer

Five Major Types of Adsorption Dryers

Adsorption dryers can be categorized into five major types. Let’s take a closer look at each type based on individual working principles, energy consumption, energy-saving features, and applications.

Heatless Regeneration Adsorption Dryer

This desiccant air dryer is suitable for applications with high dew point requirements, such as the electronics and pharmaceutical industries, where dew points can reach -40℃ to -70℃. Its simple structure and easy maintenance make it ideal for locations with limited space.

- Working Principle: A heatless regeneration adsorption dryer operates based on the pressure swing adsorption (PSA) principle. When the water vapor in the compressed air has a high partial pressure, the desiccant material adsorbs the moisture. During regeneration, the partial pressure of water vapor is lowered, allowing the adsorbed moisture to be desorbed and released back into the gas phase. The system consists of two parallel desiccant vessels alternating between drying and regeneration cycles.

- Energy Consumption Analysis: These dryers consume about 8% to 14% of their compressed air flow in purge air during the regeneration process.

- Stable outlet dew point and minimum regeneration gas consumption.

- Easy maintenance and low initial costs make it suitable for settings with low initial costs.

Heated Regenerative Adsorption Dryer

These adsorption dryers are ideal for industries that have stringent air quality requirements. These include pharmaceuticals, glass manufacturing, petrochemical manufacturing, energy production, food processing, etc.

- Working Principle: Heated regenerative adsorption dryer works on the temperature swing adsorption principle. The desiccant absorbs moisture at standard temperature and releases it when heated. The regeneration process has two steps: heating desorption and cooling regeneration. A small amount of dry compressed air helps enhance the heat transfer efficiency, reducing reliance on purge air.

- Energy Consumption Analysis: This dryer has higher energy efficiency because less compressed air is wasted during regeneration. It comes with the following energy-saving features:

- Lower operational costs compared to heatless systems, the average regeneration gas consumption is only 4% to 8%.

- Ideal for applications requiring stable dew point

Blower Heated Adsorption Dryer

A blower-heated adsorption dryer is required in industries that need high volumes of dry air. These industries include chemical processing, manufacturing, textiles, food processing, and transportation.

- Working Principle: This industrial air dryer is based on the heated regeneration adsorption dryer with an added independent blower. By integrating heat and moisture exchange technologies, it efficiently removes water vapor from compressed air without additional compressed air consumption.

- Energy Consumption Analysis: This type minimizes compressed air usage and significantly reduces operational costs. It is

- Highly energy efficient, can save more than 30% of comprehensive energy consumption.

- Suitable for high-flow applications.

Compression Heated Adsorption Dryer

Compression heated adsorption dryers are ideal for large-scale operations with high energy demands. They are also preferred in extreme environmental conditions. This includes hazardous sites with dust and flammable gases. Besides, these dryers are utilized in industries like oil and gas, power plants, electronics, and pharmaceuticals.

- Working Principle: The compressor dryer utilizes the heat from high-temperature air discharged by the compressor to directly regenerate the desiccant.

- Energy Consumption Analysis:Compression heated adsorption dryer is highly energy-efficient as it repurposes existing heat without additional energy consumption.

- High adsorbent utilization rate and small gas pressure loss.

- Suitable for applications requiring high flow rates and low dew points.

Modular Heatless Adsorption Dryer

Modular heatless adsorption dryer is used in point-of-use installations in small or specialized industries. This includes pharmaceuticals, oil and gas, and food processing.

- Working Principle: A modular heatless adsorption dryer is a compact version of the traditional twin-tower, featuring a modular structure and a straight-through adsorption chamber. This design makes the adsorption efficiency of the adsorbent.

- Energy Consumption Analysis: This energy-saving dryer to heatless systems but more optimized for smaller-scale operations.

- Compact and modular design.

- Easy to install and maintain, making it ideal for flexible and decentralized applications.

Practical Benefits of Energy-Efficient Adsorption Dryers

In today’s highly competitive industrial environment, choosing energy-efficient and high-performance adsorption dryer brands and products is of crucial significance. Energy-efficient adsorption dryers provide it along with the following advantages:

- Cost Savings: Reduced energy consumption, lower utility bills, and operational costs.

- Lower Environmental Impact: Energy-efficient systems that help minimize carbon footprints and support sustainability goals.

- Improved System Reliability and Longevity: Consistent performance reduced wear and tear, extending equipment lifespan.

- Enhanced Productivity: Preventing moisture-related issues, energy-saving dryers ensure uninterrupted operations. This reduces downtime and increases efficiency.

- Regulatory Compliance: Many industries have strict regulations regarding air quality. Energy-efficient adsorption dryers help businesses effortlessly meet these requirements and maintain quality standards.

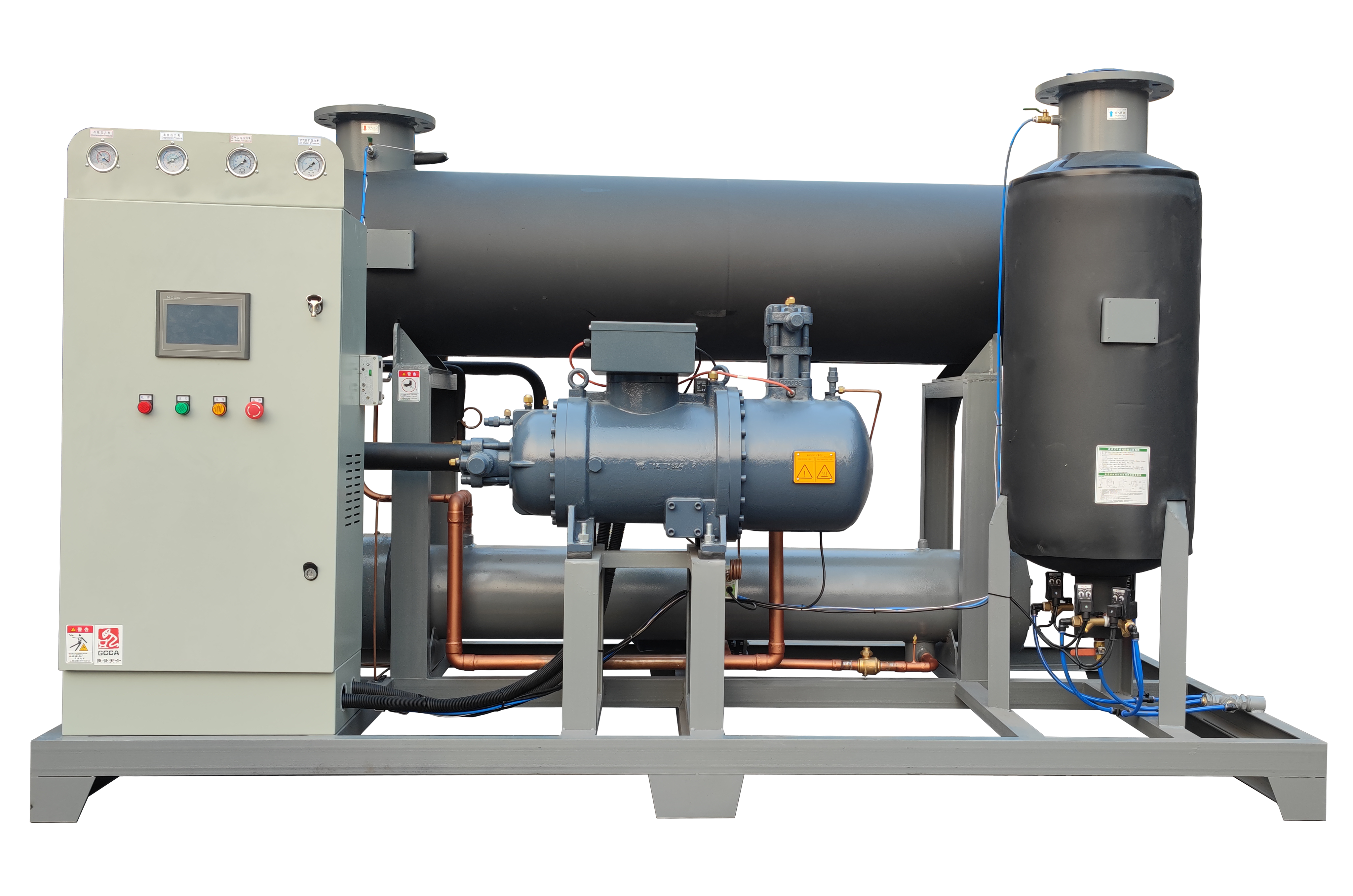

Contact Lingyu to Find the Right Adsorption Dryer for Your Needs

Lingyu has collaborated with renowned brands and customers worldwide and has earned a reputation for quality and innovation. We offer a comprehensive range of energy-saving adsorption dryers. We provide all five types of adsorption dryers discussed in this guide so you can find the right solution for your specific needs. Whether you prioritize cost savings, environmental sustainability, or operational efficiency, Lingyu has the perfect adsorption dryer for you.

Visit Lingyu today to explore our products and learn more about our commitment to excellence. Contact us for expert guidance, tailored recommendations, and unparalleled customer support. Let Lingyu help you achieve your industrial goals with cutting-edge adsorption drying solutions.