Compressed air containing moisture and water vapors can be a real pain in the neck across various industrial and residential settings. It can cause damage to machinery and installations and even contaminate our final products, severely damaging the company’s reputation. A compressed air dryer is a reliable solution, as it removes moisture and water vapor, supplying clean and pure air for facilities.

Future Market Insights predicts that by 2033, the market value of compressed air dryers will reach $10.4 billion[1]. This increasing demand is due to increasing awareness about the need and advantages of compressor dryers across many industries like construction, manufacturing, automotive, food and beverage, pharmaceuticals, and electronics.

Table of Contents

ToggleWhat is a Compressed Air Dryer?

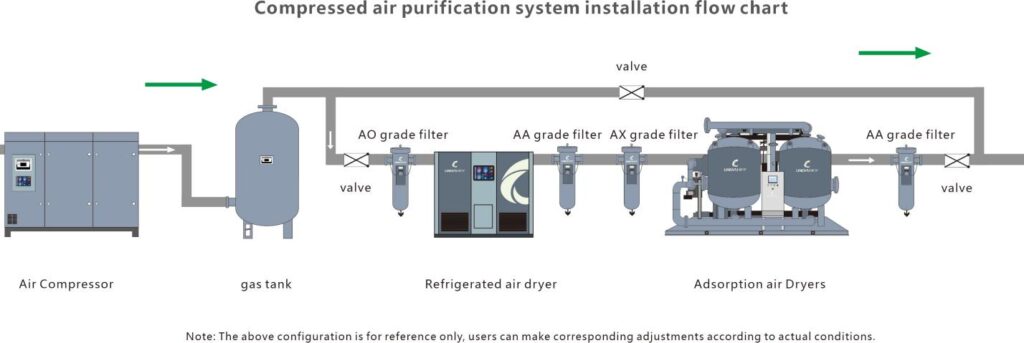

A compressed air dryer is an equipment that removes the moisture from compressed air and ensures optimal performance in various industrial applications. Different air dryers work in different ways. However, their main purpose is to prevent condensation, rust, and contamination in pneumatic systems. Compressor dryer systems make use of methods like absorption, filtration, refrigeration, and diffusion to maintain the air’s dryness and cleanliness.

Working Principle of Compressed Air Dryer

If we explain the working principle at the most basic level, the compressed air dryers separate the moisture and vapor from the industrial process air. The actions and ways of the dryer that protect compressed air from moisture vary depending on the type of air dryer used. The two most popular types are:

- Refrigerated Dryers

- Desiccant Dryers

Refrigerated Dryers

Refrigerated air dryers are widely preferred due to their minimal maintenance requirements and cost-effectiveness. Their working principle is based on reducing air humidity through rapid cooling, condensation, and moisture removal. They come in two main types:

- Air–Cooled Refrigerated Air Dryers: These dryers remove moisture fromcompressed air by cooling it with ambient air. The moisture in the air is condensed into liquid for removal and drainage.

- Water-Cooled Refrigerated AirDryers: These dryers use water to cool the condenser within the refrigeration system, which in turn cools the compressed air. The moisture in the compressed air is condensed during the cooling process and is then removed through an efficient drainage system.

Desiccant Dryers

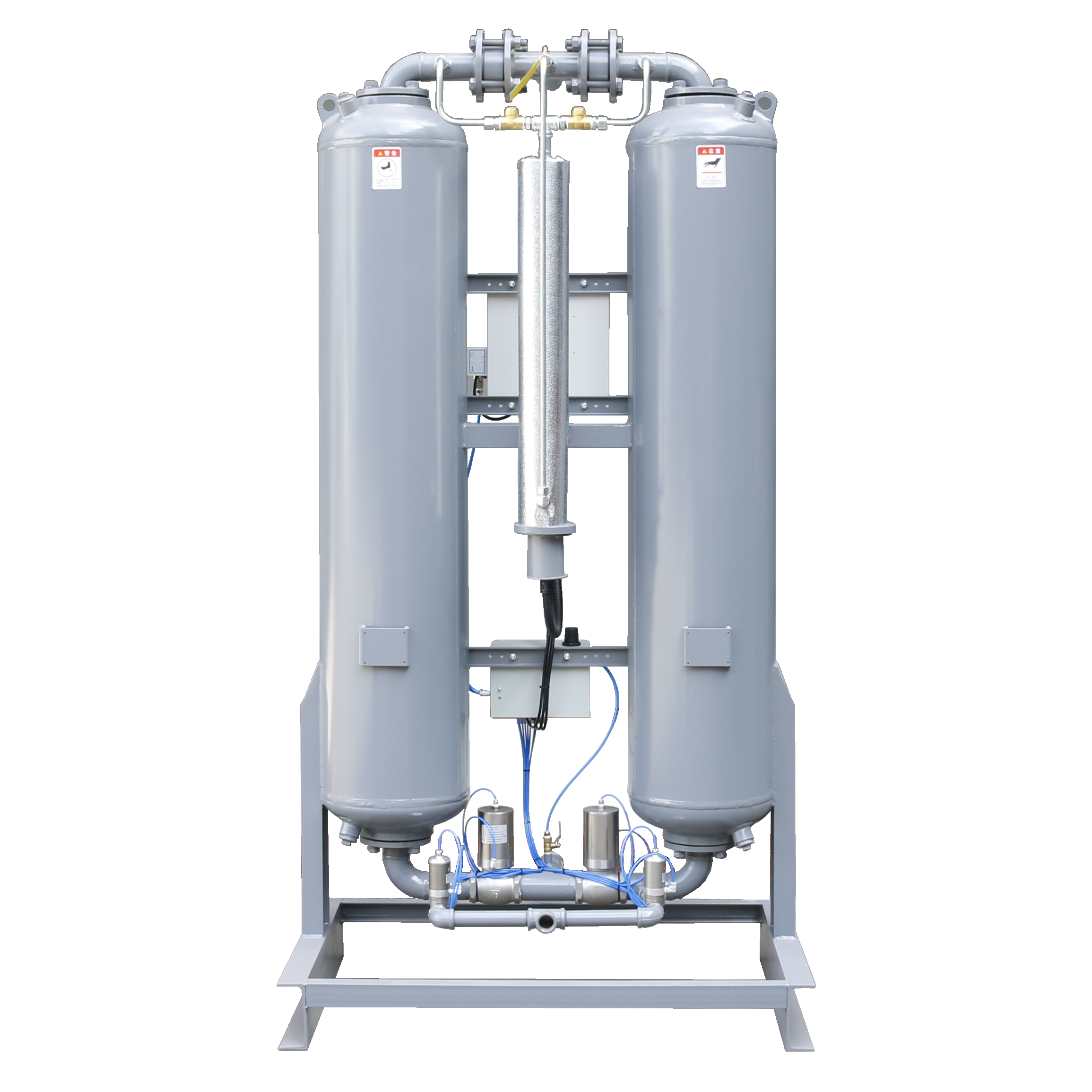

Desiccant dryers utilize a two-tower system for efficient moisture removal. One tower dries the air by adsorbing moisture onto the desiccant, while the other regenerates the desiccant, removing the absorbed moisture. It is the best choice for removing air moisture in extremely low temperatures or moisture-intolerant environments. It has a further two types:

- Heated Desiccant Dryers: These dryers use an internal heat source to warm the desiccant material. It reduces the need to purge air.

- Heatless Desiccant Dryers:These dryers remove moisture through the use of purge air. The dew points in these dryers range from -40°C to -73.3°.

Applications of Compressed Air Dryers

The compressed air system is essential for various industries and has wide applications in both various industrial and professional sectors. Here are just a few examples:

| Ozone Generation | Laboratory Analyzers | Waveguide Drying | Environmental Chambers | Dry Sprinkler Systems | Air Brushing |

| Pneumatic Automation Systems | Outdoor HVAC Controls | Gas Chromatographs | Medical Air Compressors | Electronic Chip Testing | Robotic Machinery |

| Dental Air Compressors | Dry Nitrogen Replacement | Car Wash Controls | Bus Door & Locking Systems | Air Bearings | Graphic Printers |

| CEMS Systems | Vortex Tubes | Air Turbines | FTIR Spectrometers | Antenna Pressurization | Air Operated Pumps |

Considerations for Selecting a Compressed Air Dryer

When selecting a compressed air dryer, take the following points into consideration to ensure you are investing in the right equipment:

- Dew Point’sStability: Ensure the air dryer for compressed air can consistently achieve and maintain the desired dew point. It will prevent moisture-related issues.

- Operating Conditions and Technical Requirements: Assess the dryer’s compatibility with the system’s pressure, temperature, and airflow requirements.

- Equipment Size and Installation Space:We should evaluate the physical dimensions of the dryer and the available installation space.

- Investment and Energy Cost:Consider the initial purchase price of an industrial air dryer for a compressor and the ongoing energy consumption to find a balance between affordability and efficiency.

Lingyu Offers One-stop Compressed Air Dryer Solutions for Diverse Applications

Lingyu is a leading manufacturer of compressed air dryers in China. Founded in 2009, we provide one-stop solutions for all compressed air treatment needs. Our focus is on quality and reliability. We are a national high-tech enterprise and a leader in drafting the national “Compressed Air” standard.

Lingyu provides specialized products tailored for various industrial working conditions. Our dryers have low failure rates and ensure high air quality. We emphasize low energy consumption, making our solutions cost-effective. With over 50 R&D patents, our products are innovative and efficient.

Our facilities cover 13,000 square meters, and our annual sales reach $30 million. Over 2,800 domestic and international customers trust us. Lingyu is the right choice for businesses looking for a reliable air dryer supplier.

Reference:

[1] Air Compressor Filters and Compressed Air Dryers Market Snapshot (2023 to 2033). Available at: https://www.futuremarketinsights.com/reports/air-compressor-filters-and-compressed-air-dryers-market (Accessed: 9 August 2024)