Have questions? Contact us

FEEDBACK

Connect with us

Address

No.3, 2nd Street, yuanle Road, Dongsheng Town, Zhongshan City, Guangdong Province

Phone

№1:(WeChat/WhatsApp):008618628146428

№2:(WeChat/WhatsApp):008613823294942

Phone

№1:(WeChat/WhatsApp):+8618628146428

№2:(WeChat/WhatsApp):+8613823294942

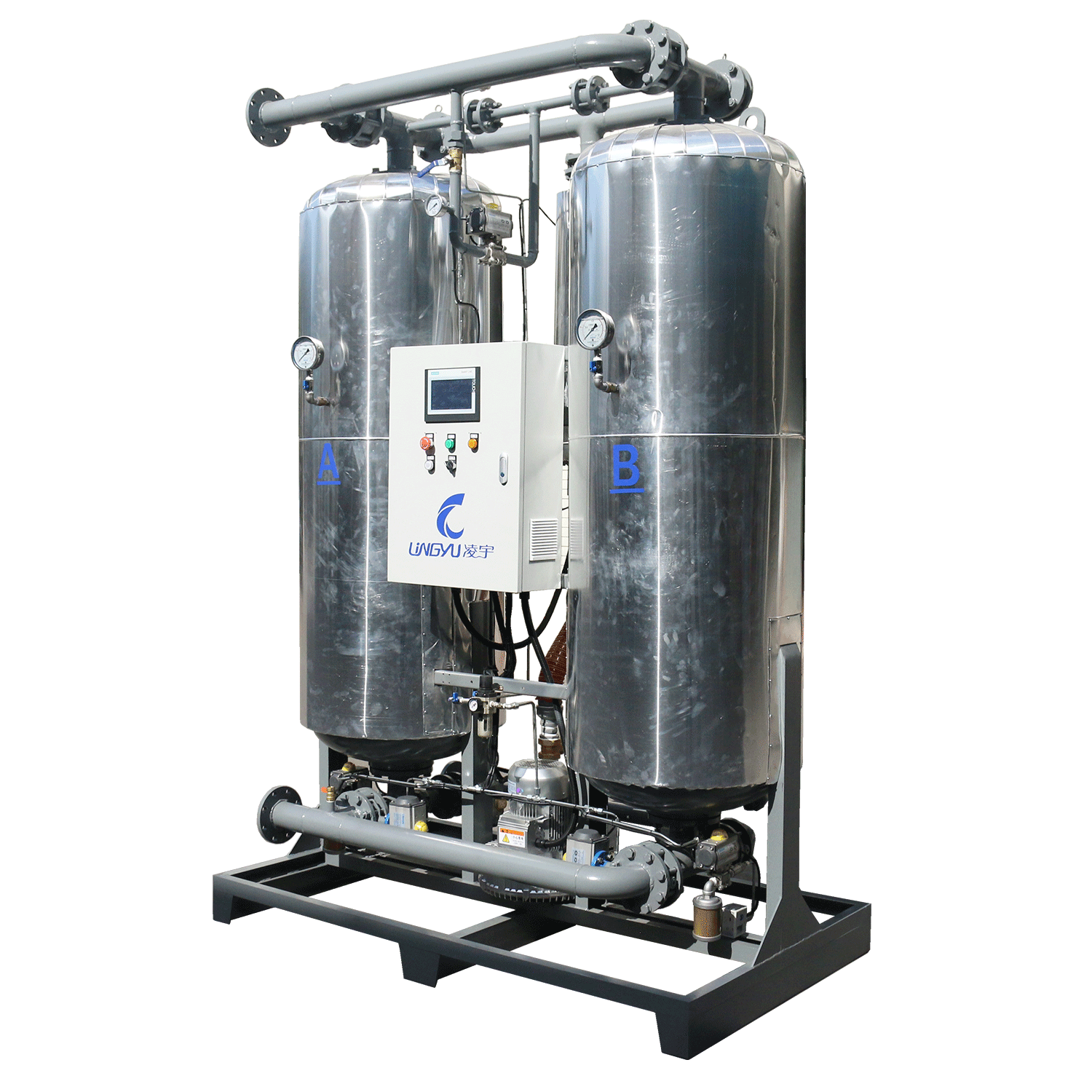

The zero-gas-consumption blast heat regeneration adsorption dryer is based on the micro-gas-consumption blast heat regeneration adsorption dryer, with an additional intermediate cooler. The ambient air sucked in by the blower is heated by the heater to heat the adsorbent to desorb moisture. During the cooling stage, the hot air circulates through the intermediate cooler and the regeneration tower, and the regeneration tower is cooled through a continuous closed cycle. The entire regeneration process does not consume compressed air.

The zero-gas-consumption blast heat regeneration adsorption dryer is based on the micro-gas-consumption blast heat regeneration adsorption dryer, with an additional intermediate cooler. The ambient air sucked in by the blower is heated by the heater to heat the adsorbent to desorb moisture. During the cooling stage, the hot air circulates through the intermediate cooler and the regeneration tower, and the regeneration tower is cooled through a continuous closed cycle. The entire regeneration process does not consume compressed air.