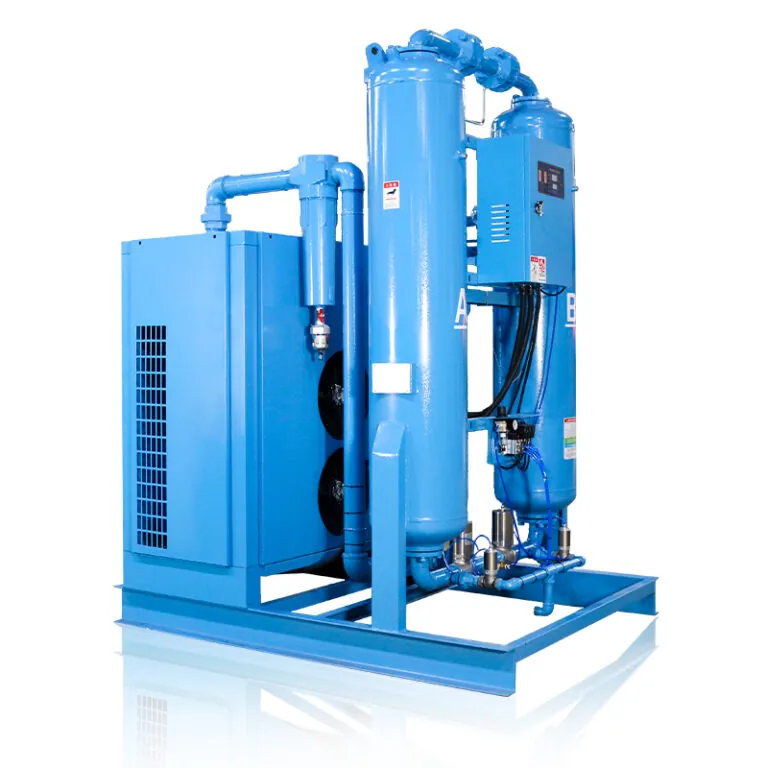

Introducing Lingyu: a place where cutting-edge DC Series Combined Compressed Air Dryer Systems redefine air quality standards through innovation and precision. Designed to optimize performance and efficiency, each compressed air dryer system is engineered to cater to applicable fluids, including compressed air and non-corrosive air. At Lingyu, we adhere to strict standards, ensuring that our compressed air dryer systems are rated for specific inlet pressures and temperatures, offering customizable options to meet the unique needs of our customers. Join us as we delve into how Lingyu’s compressed air dryer systems are revolutionizing air treatment solutions for a variety of industries.

Unveiling the Versatility of Lingyu’s Compressed Air Dryer Systems

Lingyu’s DC Series Compressed Air Dryer Systems are versatile solutions that cater to a wide range of applicable fluids, including compressed air and non-corrosive air. With rated inlet pressure specifications ranging from 0.6MPa to 1.0MPa and customizable pressure levels, Lingyu’s compressed air dryer systems offer flexibility to suit diverse operational requirements. Additionally, the rated air inlet temperature of 50℃, with a limit of ≤80℃, ensures optimal performance and efficiency across various applications.

By embracing Lingyu’s compressed air dryer systems, businesses can enhance the quality of their air treatment processes, safeguarding equipment and operations from moisture and impurities. The DC Series sets a new standard for compressed air dryer systems, providing reliable and customizable solutions that address the unique needs of different industries.

Precision Engineering for Superior Performance

At Lingyu, precision engineering is at the core of our compressed air dryer systems, ensuring that each system delivers superior performance and efficiency. Our commitment to excellence is reflected in the rigorous testing and quality control measures that govern the production of our compressed air dryer systems. With rated inlet pressures tailored to industry standards and customizable pressure levels, Lingyu’s systems are designed to meet the specific demands of diverse applications.

The advanced design of Lingyu’s compressed air dryer systems guarantees optimal air quality and moisture removal, protecting equipment and processes from potential damage. Businesses can rely on Lingyu’s precision-engineered systems to enhance operational efficiency and maintain air quality standards with confidence.

Customizable Solutions for Enhanced Flexibility

Lingyu’s DC Series Compressed Air Dryer Systems offer customizable solutions that provide enhanced flexibility to meet the unique requirements of different industries. With adjustable pressure levels and a range of customizable options, businesses can tailor Lingyu’s compressed air dryer systems to suit their specific operational needs. Whether dealing with compressed air or non-corrosive air, Lingyu’s systems ensure reliable performance and efficiency.

By choosing Lingyu’s compressed air dryer systems, businesses gain access to a versatile and customizable solution that adapts to their evolving needs. The DC Series exemplifies Lingyu’s dedication to innovation and quality, offering tailored solutions that optimize air treatment processes and elevate air quality standards across various industries.

Conclusion:

In conclusion, Lingyu’s DC Series Compressed Air Dryer Systems represent a cutting-edge solution for businesses seeking to enhance air quality and optimize operational efficiency. With a focus on applicable fluids such as compressed air and non-corrosive air, Lingyu’s systems are rated for specific inlet pressures and temperatures, offering customizable options to meet diverse requirements. Put your trust in Lingyu for compressed air dryer systems that lead the industry in terms of performance, dependability, and flexibility—setting new standards for air treatment solutions in a variety of sectors.