Nitrogen is a naturally stable gas that’s why it is used extensively in many industries like food packing, electronics, mining, and pharmaceuticals. It is a colorless, tasteless, and non-toxic gas. Many industries depend on nitrogen to prevent oxidation and control reactions in order to maintain quality.

Many industries use nitrogen cylinders but this nitrogen source is expensive and is a huge hassle to tackle with. It often disturbs the production process if the delivery is not smooth. A nitrogen gas generator provides an on-demand and unlimited supply of nitrogen gas. It effectively solves the inefficiencies that come with using nitrogen cylinders. In the following, we will explain the importance of nitrogen gas generators to give you a clear understanding.

Table of Contents

ToggleIndustrial Significance of Nitrogen Gas

Nitrogen gas has an important role in running operations in many industries. Its unique properties, like the ability to make multiple bonds with other compounds and elements, make it exceptionally versatile. That’s why we use nitrogen gas in many forms across many industries. The main industrial use of this gas is to create ammonia for making materials like explosives, fertilizer, and others. But there are a lot of other uses of nitrogen gas than we realize.

In fact, according to Statista Research Department, due to considerable demand and growth, the size of the nitrogen gas market is expected to value about 193 billion US dollars by 2030[1]. This remarkable growth is due to the rising need for quality control and safety among expanding industries. It makes nitrogen gas generators a valuable asset for companies who want to meet nitrogen demand efficiently.

Understanding Nitrogen Gas Generators

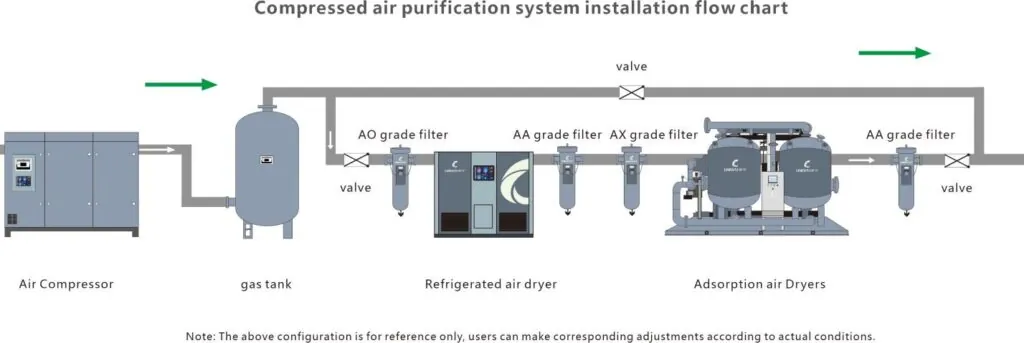

Nitrogen gas generators are sophisticated systems available in both stationary and mobile configurations. They work by separating the nitrogen and oxygen molecules from each other within compressed air to get a purified nitrogen supply.

There are two common types of nitrogen gas generators used across various industries:

- PSA (Pressure Swing Adsorption) Nitrogen Generators: PSA nitrogen gas generator employs carbon molecular sieves and other adsorbent materials to capture oxygen and other trace gases from compressed air, thereby producing a stream of high-purity nitrogen. The process alternates between two adsorption towers. PSA nitrogen generator gives a continuous supply of nitrogen at high purity levels of usually 95% to 99.999%.

- Membrane Nitrogen Generators: In these systems, compressed air is passed through a semi-permeable membrane. This membrane allows oxygen, water vapor, and other gases to pass through while remaining. Such generators are used for applications requiring lower nitrogen purity levels (90% to 99.5%), like tire inflation or fire prevention systems.

Applications of Nitrogen Gas Generators

Let’s discuss some of the uses of nitrogen gas generators across various industries:

- Chemical Blanketing

In manufacturing facilities and chemical plants, there is a higher risk of fires and explosions. The on-site nitrogen generator lowers the level of oxygen below explosive limits.

- Laser Cutting

In the steel industry, nitrogen gas is commonly used as a purging gas. It helps blow away the molten material. This is very important to achieve a stronger aluminized or stainless steel product. Through this process, the product also becomes more resistant to corrosion.

- Food Packaging

For food processing companies, nitrogen gas generators are typically used to remove the oxygen from perishable food packages. It increases the shelf life of these products by preventing oxidation and spoilage.

- Pharmaceuticals

A nitrogen generator creates a sterile and oxygen-free environment for manufacturing and storage. It protects sensitive compounds from oxidation and degradation and guarantees consistent quality.

Benefits of Using Nitrogen Generators

Nitrogen gas generators are the key solution for industries that need a consistent and reliable nitrogen supply in their systems. This nitrogen generation system produces nitrogen on-site, so we don’t have to depend on external suppliers. Here are some amazing benefits the industrial nitrogen generator offers:

1. Cost-Effectiveness

A nitrogen generator is a wise investment that saves money over time. By producing nitrogen on-site, we avoid the recurring costs of cylinder deliveries and storage. The initial expense of a generator pays off. This reduces long-term expenses significantly.

2. On-Demand Production

With a nitrogen generator, we have nitrogen whenever we need it. We don’t have to wait for suppliers or deal with delays. This on-demand access boosts productivity and gives us control over our operations without disruptions.

3. Quality Control

With a nitrogen gas generator, we have full control over nitrogen purity levels when we generate on-site nitrogen. It eliminates the risk of impurities that could compromise product quality, helps maintain reliable processes, and upholds industry standards.

Top Nitrogen Gas Generator Choices from Lingyu

Lingyu, a reliable high-tech enterprise, specializes in manufacturing high-end and dependable nitrogen gas generators. For businesses that require reliability and high performance, Lingyu is the name you can trust. Here are Lingyu’s highly recommended nitrogen gas generators:

Need stable and high-purity nitrogen? This nitrogen generator with 99.5% purity is perfect. It’s built to handle daily operations like food packaging and general manufacturing. Dependable, efficient, and budget-friendly-this model hits all the right notes.

For industries that demand extreme purity, like electronics and pharmaceuticals, this nitrogen generator with this 99.99% purity generator is your answer. It supplies pure and clean nitrogen, which is perfect for sensitive applications.

Equipped with a digital touch screen, both nitrogen generators from Lingyu can provide you with online real-time monitoring of nitrogen purity and flow rate, helping you better control the operation. Besides, these two models feature automatic switch-on and off functions, as well as alarm and shutdown of unqualified nitrogen. This way, they can guarantee the purity and quality of nitrogen in a safe and efficient way.

Conclusion

Nitrogen gas generators are important for industrial operations. They’re cost-effective, efficient, and deliver pure nitrogen on demand. No delays, no interruptions. You’re set for smoother operations, better quality control, and significant savings in the long run.

Lingyu’s on-site nitrogen generators take it up a notch. These generators offer different purity options that cover all your needs, whether it’s for food packaging or high-precision electronics. Want to know more about how Lingyu can help you specifically with your industry’s nitrogen gas needs? Contact our professional team to help you with it!

Reference

[1] Global nitrogen gas market value 2020-2030. Available at: https://www.statista.com/statistics/1428583/global-nitrogen-gas-market-value/. (Accessed: 13 November 2024)