What Is an Air Dryer Governor?

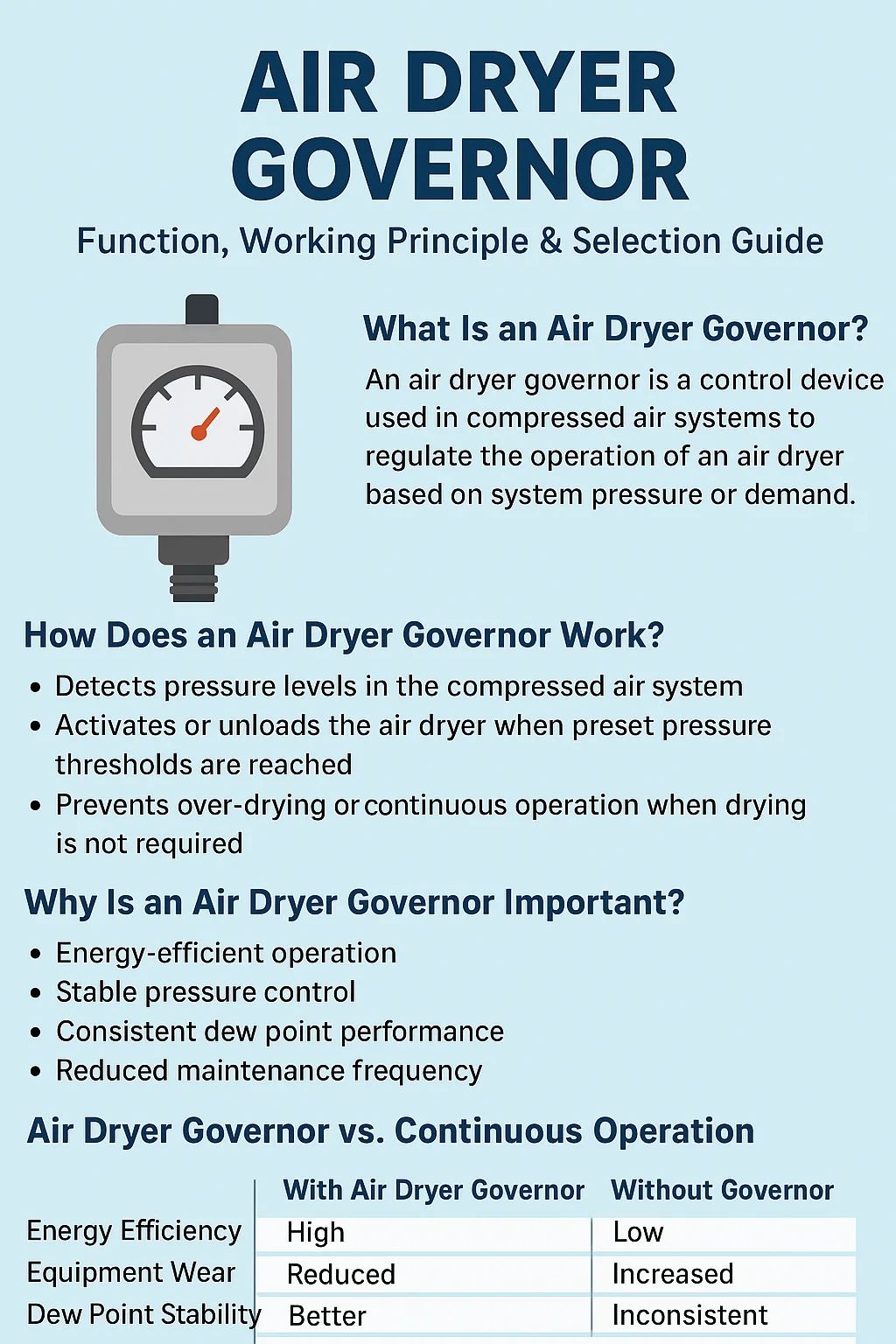

An air dryer governor is a control device used in compressed air systems to regulate the operation of an air dryer based on system pressure or demand.

Its primary function is to optimize air dryer performance, reduce unnecessary energy consumption, and ensure a stable supply of dry compressed air.

Air dryer governors are commonly found in industrial compressed air systems, especially where air quality, pressure stability, and energy efficiency are critical.

How Does an Air Dryer Governor Work?

An air dryer governor monitors system pressure and operating conditions, then controls when the air dryer should run or stop.

In simple terms, it:

Detects pressure levels in the compressed air system

Activates or unloads the air dryer when preset pressure thresholds are reached

Prevents over-drying or continuous operation when drying is not required

By matching dryer operation with actual system demand, the governor helps extend equipment life and lowers operating costs.

Why Is an Air Dryer Governor Important?

Using an air dryer without proper control can lead to:

Excessive energy consumption

Unnecessary wear on compressors and dryers

Unstable pressure and inconsistent air quality

An air dryer governor helps solve these issues by providing:

Energy-efficient operation

Stable pressure control

Consistent dew point performance

Reduced maintenance frequency

This is especially important in applications such as manufacturing, automotive, food processing, and electronics production.

Air Dryer Governor vs. Continuous Operation

| Aspect | With Air Dryer Governor | Without Governor |

|---|---|---|

| Energy Efficiency | High | Low |

| Equipment Wear | Reduced | Increased |

| Dew Point Stability | Better | Inconsistent |

| Operating Cost | Optimized | Higher |

For modern industrial systems, using a governor is no longer optional—it is a best practice.

Relationship Between Air Dryer Governor and Refrigerated Air Dryers

A refrigerated air dryer removes moisture by cooling compressed air and condensing water vapor.

When combined with an air dryer governor:

The dryer only operates when moisture removal is necessary

Energy consumption is significantly reduced during low-load periods

Overall system efficiency improves

This combination is ideal for applications requiring moderate dew point levels (typically +2°C to +10°C).

Recommended for:

General manufacturing

Automotive assembly

Pneumatic tools

Packaging lines

Relationship Between Air Dryer Governor and Desiccant Air Dryers

A desiccant air dryer uses adsorption materials to achieve very low pressure dew points (−20°C to −70°C).

In these systems, an air dryer governor plays an even more critical role.

Benefits include:

Optimized regeneration cycles

Reduced purge air loss

Stable ultra-dry air quality

Lower total cost of ownership

This setup is essential for industries requiring ultra-dry compressed air.

Recommended for:

Electronics manufacturing

Pharmaceutical production

Instrument air systems

Chemical and petrochemical plants

How to Choose the Right Air Dryer with a Governor

When selecting an air dryer and governor combination, consider:

Required Dew Point

Moderate → Refrigerated Air Dryer

Very Low → Desiccant Air Dryer

Operating Environment

Stable indoor conditions

High humidity or harsh environments

Energy Efficiency Goals

Governor-controlled systems significantly reduce long-term costs

System Size and Air Demand

Larger systems benefit more from intelligent control

Conclusion

An air dryer governor is a key component in any modern compressed air system.

When properly integrated with refrigerated air dryers or desiccant air dryers, it ensures optimal performance, stable air quality, and energy-efficient operation.

If you are upgrading or designing an industrial compressed air system, choosing the right air dryer and governor combination is essential for long-term reliability and cost control.