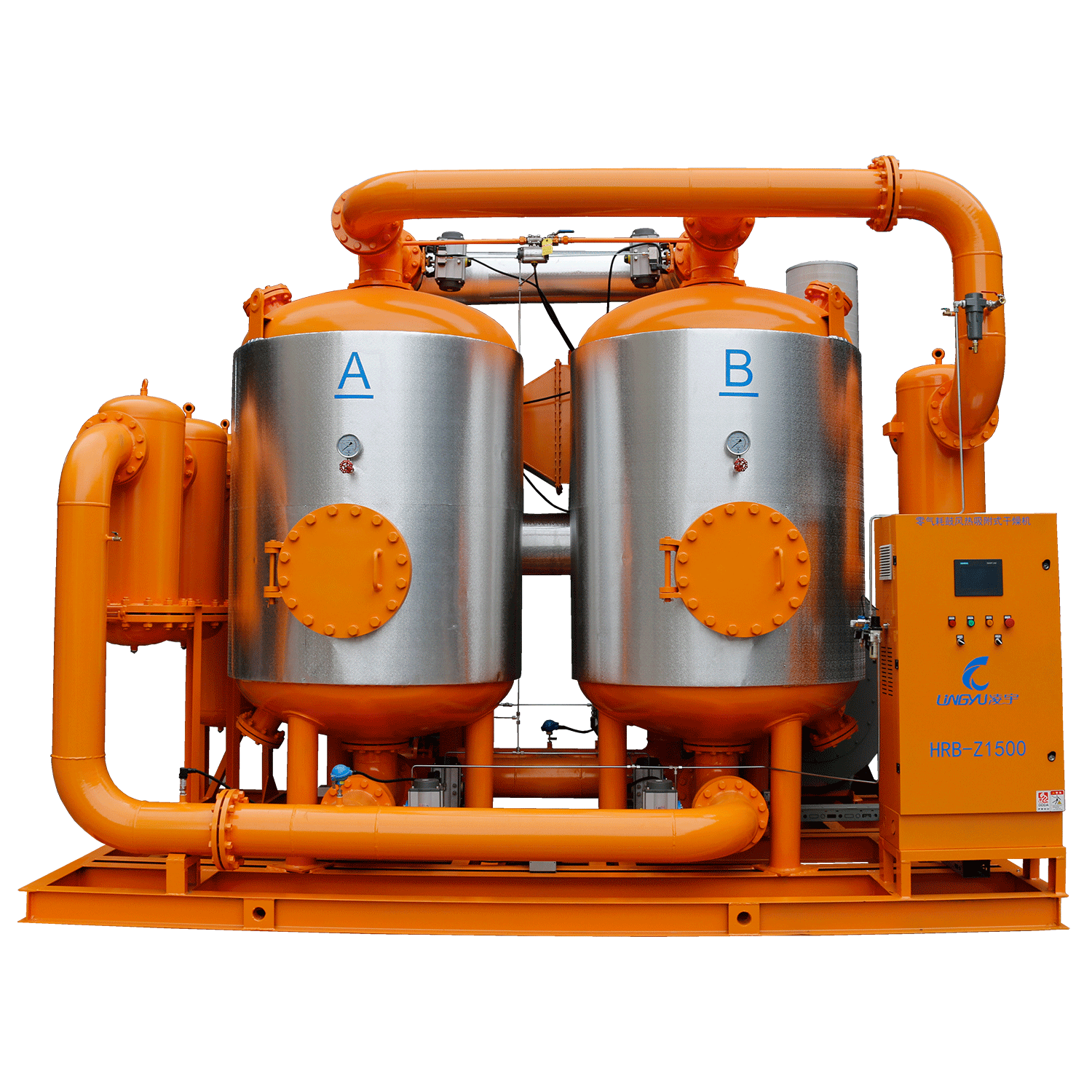

Blower & Zero Purge Adsorption Dryers – Energy-Saving Air Drying Solutions

The blower and zero-purge adsorption dryer represents an advanced, energy-efficient air drying technology. Based on the principle of heat regeneration, this system eliminates compressed air consumption during regeneration, ensuring stable performance with reduced operational costs.

How It Works

The zero-gas-consumption blast heat regeneration adsorption dryer is an upgrade of the micro-gas-consumption type, featuring an additional intermediate cooler. Ambient air is drawn in by a blower and heated by an electric heater to regenerate the adsorbent by desorbing moisture.

During the cooling stage, the heated air passes through the intermediate cooler and the regeneration tower in a closed-loop cycle. This closed system ensures that the regeneration process does not consume any compressed air, improving efficiency while maintaining a low outlet dew point.

Operating Conditions & Technical Requirements

Applicable Fluids: Compressed air, non-corrosive air

Rated Inlet Pressure: 0.7MPa (0.6–1.0MPa allowed; customizable options available)

Rated Inlet Temperature: 10℃–30℃ (max. ≤40℃)

Inlet Air Dew Point: ≤25℃

Regeneration Gas Consumption: 0%

Outlet Pressure Dew Point: -20℃ / -40℃ (optional)

Rated Ambient Temperature: 35℃ (usable range: 2℃–40℃)

Cooling Water Temperature: ≤32℃

Cooling Water Pressure: 0.2–0.6MPa

Technical Parameters

| Processing Capacity (m³/min) | Gas Connection | Total Power (kW) | Dimensions (mm) L×W×H |

|---|---|---|---|

| 13.5 | DN50 | 7.5 | 1390×970×2297 |

| 25.0 | DN80 | 14.2 | 1800×1050×2597 |

| 45.0 | DN100 | 27.5 | 2400×1500×2852 |

| 75.0 | DN125 | 41.1 | 2750×1840×2888 |

| 120.0 | DN150 | 63.8 | 3500×2200×3341 |

| 160.0 | DN200 | 89.0 | 3900×2420×3500 |

| 260.0 | DN250 | 136.4 | 5200×2500×3300 |

Note: For air volumes above 260 m³/min or special material/temperature requirements, please contact us or an authorized dealer for customized solutions.

Where Are Compressed Air Dryers Used?

Compressed air dryers are essential for maintaining air quality across diverse industries and applications, including:

Laboratory analyzers and ozone generators

Electronic chip testing and robotic machinery

Medical and dental air compressors

Food and beverage packaging

Pneumatic automation systems

Environmental chambers and HVAC control systems

Laser cutting, air turbines, and CEMS systems

Why Choose Lingyu Desiccant Air Dryer?

Lingyu offers more than just high-quality compressed air dryers. As a professional air treatment and gas purification manufacturer, we provide:

Comprehensive air purification and filtration equipment

Custom-engineered air quality systems tailored to your process needs

Technical support and system optimization consulting

Users Often Want to Know

Potential users often ask about:

System integration: How to pair the dryer with existing air compressor setups

Maintenance needs: Filter replacement frequency and adsorbent lifespan

Energy efficiency: How much energy can be saved using zero-purge technology

Customization options: Temperature, dew point, and material adaptability

Operational reliability: Expected service life and control precision under varying loads

Contact Us

Need assistance selecting the right compressed air dryer?

Our team is ready to help you design an energy-efficient, low-maintenance, and cost-effective air treatment system that perfectly fits your industrial needs.

For more product information

2. Customized high-performance adsorbent, 20% filling margin;

3. Branded high-pressure blower, high-performance pneumatic valve, high-efficiency cooler designed by HTFS software, reliable performance and long life;

4. 304 stainless steel control gas pipeline, specially designed diverter, highadsorbent utilization rate and low gas pressure loss;