What Are Industrial Air Dryer Systems?

Industrial air dryer systems are essential components of compressed air systems, designed to remove moisture from compressed air before it reaches downstream equipment and processes.

Moisture in compressed air can cause corrosion, equipment failure, product contamination, and production downtime. By controlling humidity and dew point, air dryer systems help ensure stable performance, long equipment life, and consistent product quality.

Industrial air dryer systems are widely used in manufacturing, automotive, food & beverage, electronics, pharmaceuticals, chemical processing, and energy industries.

Why Moisture Control Is Critical in Compressed Air

Compressed air naturally contains water vapor. As air is compressed and cooled, moisture condenses and creates serious risks:

Corrosion in pipelines and valves

Damage to pneumatic tools and instruments

Unstable pressure and flow

Product defects and contamination

Increased maintenance and energy costs

An industrial air dryer system removes this moisture and delivers dry, clean air suitable for specific application requirements.

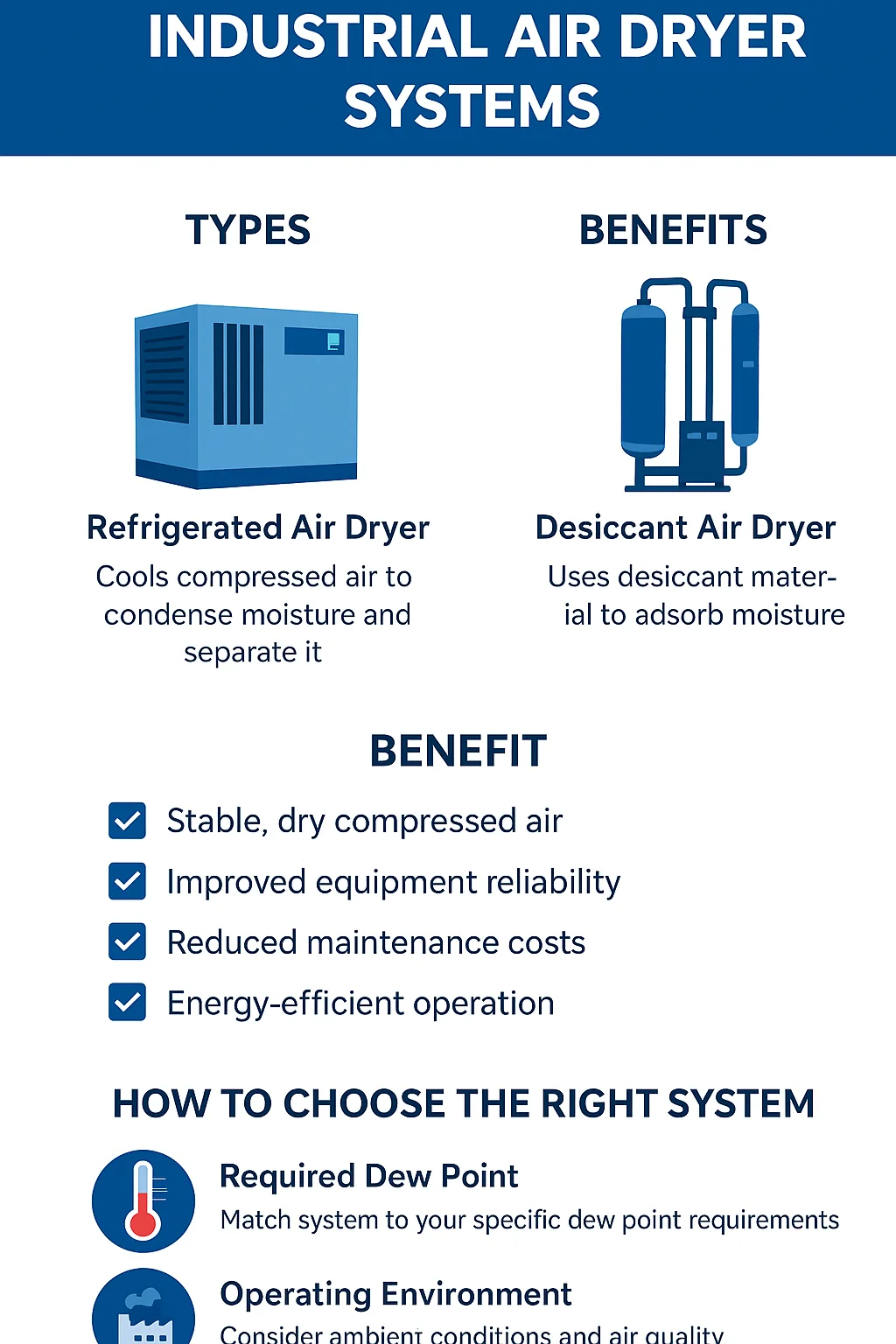

Main Types of Industrial Air Dryer Systems

Refrigerated Air Dryer Systems

Refrigerated air dryers remove moisture by cooling compressed air, causing water vapor to condense and drain away.

Key characteristics:

Stable and energy-efficient

Ideal for general industrial use

Lower initial and operating cost

Typical pressure dew point: +2°C to +10°C

Common applications:

General manufacturing

Automotive assembly

Pneumatic tools

Packaging lines

Desiccant Air Dryer Systems

Desiccant air dryers use adsorption materials to achieve very low pressure dew points by physically capturing moisture.

Key characteristics:

Ultra-dry compressed air

Suitable for critical and precision processes

Higher performance in harsh environments

Typical pressure dew point: −20°C to −70°C

Common applications:

Electronics manufacturing

Pharmaceutical production

Instrument air systems

Chemical and petrochemical plants

Required Dew Point Comparison Table

Choosing the correct industrial air dryer system depends heavily on the required pressure dew point. The table below provides a clear comparison:

| Application Requirement | Typical Dew Point | Recommended Air Dryer System |

|---|---|---|

| General factory air | +5°C to +10°C | Refrigerated Air Dryer |

| Automotive & assembly | +2°C to +5°C | Refrigerated Air Dryer |

| Outdoor pipelines | −20°C | Desiccant Air Dryer |

| Instrument air | −40°C | Desiccant Air Dryer |

| Electronics manufacturing | −40°C to −70°C | Desiccant Air Dryer |

| Pharmaceutical processes | −40°C | Desiccant Air Dryer |

How to Choose the Right Industrial Air Dryer System

When selecting an industrial air dryer system, consider the following factors:

1. Required Dew Point

Moderate dew point → Refrigerated air dryer

Very low dew point → Desiccant air dryer

2. Operating Environment

Stable indoor conditions

High humidity or harsh outdoor environments

3. Energy Efficiency

Intelligent control and proper sizing reduce long-term operating costs

Avoid over-drying beyond actual process needs

4. System Size and Air Demand

Large systems benefit significantly from optimized dryer selection

Continuous vs intermittent operation matters

Integrating Air Dryers into Complete Industrial Air Dryer Systems

A complete industrial air dryer system typically includes:

Air compressor

Air dryer (refrigerated or desiccant)

Air filters

Drain systems

Control and monitoring components

Proper system design ensures stable dew point control, energy efficiency, and long-term reliability.

Conclusion

Industrial air dryer systems play a critical role in maintaining compressed air quality across a wide range of industries.

By understanding dew point requirements and the differences between refrigerated and desiccant air dryers, manufacturers can select the right solution to protect equipment, improve efficiency, and ensure consistent production quality.

Whether for general manufacturing or high-precision applications, choosing the correct industrial air dryer system is essential for reliable and cost-effective compressed air operation.