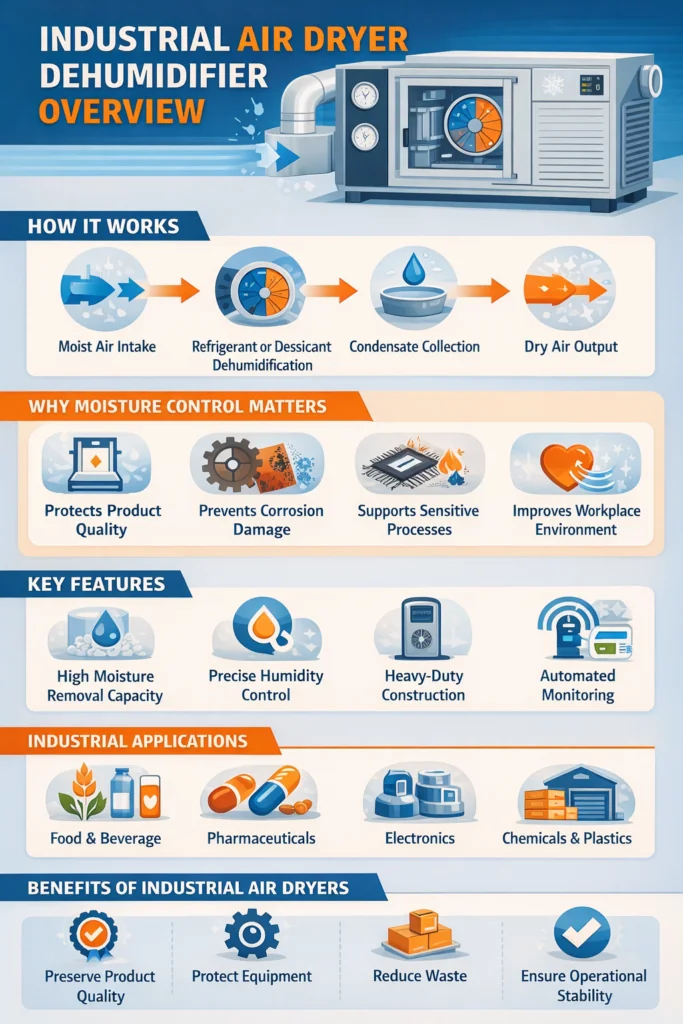

An industrial air dryer dehumidifier is a specialized system designed to remove moisture from air in large spaces and industrial processes. Unlike simple fans or household dehumidifiers, industrial units are engineered to handle high humidity levels, continuous operation, and demanding environments. By controlling air moisture, these systems improve product quality, protect equipment, and stabilize sensitive manufacturing processes.

What Is an Industrial Air Dryer Dehumidifier?

An industrial air dryer dehumidifier is a machine that extracts water vapor from air, creating a dry, controlled atmosphere. It combines principles of air drying and dehumidification — reducing humidity levels to meet precise industrial requirements. This is critical in facilities where too much moisture can damage materials, interrupt production, or lead to corrosion and mold.

Industrial units are more powerful than consumer models and are designed for high airflow capacity, robust construction, and long operating hours.

How It Works

Industrial dehumidifier dryers typically use one of two main technologies:

Refrigerant Dehumidification

In this method, humid air passes over cooled coils that lower the temperature below the dew point, causing moisture to condense and be collected. The dry air is then reheated and recirculated or discharged. This process works well in moderate temperature environments and can handle large volumes of air.

Desiccant Dehumidification

Desiccant units use drying materials (such as silica gel or molecular sieve) to absorb moisture from the air. The desiccant material holds the water vapor, and a secondary heating process regenerates the material so it can be reused. Desiccant systems perform exceptionally well in low temperatures or when very low humidity levels are needed.

Different industrial dehumidifier designs may also combine airflow control, filtration, and humidity sensors for more precise performance.

Why Industrial Dehumidifiers Matter

Moisture can be a hidden enemy in manufacturing and storage environments. Here’s why controlling humidity is essential:

● Protects Product Quality

High humidity can cause clumping, spoilage, corrosion, and chemical reactions in raw materials and finished goods. Dehumidifiers help maintain consistent quality and prolong shelf life.

● Prevents Structural and Equipment Damage

Excessive moisture promotes rust, mold growth, and condensation on surfaces and machinery. This degrades equipment reliability and increases maintenance costs.

● Supports Sensitive Processes

Industries such as pharmaceuticals, food processing, electronics, and battery manufacturing often require tightly controlled humidity conditions to ensure safety and compliance.

● Improves Workplace Environment

Lower humidity reduces mold, odors, and airborne allergens, contributing to a healthier, more comfortable workplace.

Key Features of Industrial Air Dryer Dehumidifiers

Industrial dehumidifier dryer systems are built for performance and durability. Common features include:

High Capacity Moisture Removal

Designed to process large volumes of air and remove significant amounts of water vapor.

Accurate Humidity Control

Integrated humidity sensors and digital controllers maintain precise set points for stability.

Robust Construction

Heavy-duty materials withstand long hours of operation and harsh industrial settings.

Continuous Operation

Many models support continuous or programmable cycling, ideal for large facilities.

Customizable Airflow

Adjustable blower speeds and ducting options help adapt the system to specific layouts and airflow needs.

Typical Industrial Applications

Industrial air dryer dehumidifiers are used across a wide range of sectors:

Food and Beverage

Keeping products like powdered ingredients, dried goods, and packaging environments free of moisture improves quality and safety.

Pharmaceuticals and Medical Devices

Strict humidity control helps prevent clumping, chemical changes, and contamination in sensitive products.

Electronics and Semiconductors

Moisture can damage delicate circuits and components; controlled dry air ensures reliability and performance.

Chemicals and Plastics

In processes where moisture interacts with raw resins, powders, or molded parts, dehumidification improves processing consistency.

Storage and Warehousing

Protect inventory from mold, condensation, and humidity-related degradation during storage or shipping preparation.

Choosing the Right Industrial Air Dryer Dehumidifier

When selecting a system, consider the following:

✔ Required Humidity Level

Different applications call for different humidity targets. Desiccant systems often reach very low dew points, while refrigerant types are efficient for general moisture control.

✔ Operating Environment

Temperature, airflow requirements, and space size influence the best technology choice.

✔ Airflow Capacity

Match the unit’s capacity to the volume of air in your workspace or process.

✔ Integration and Control

Look for models with digital controls, sensors, and remote monitoring for easy system management.

✔ Maintenance Needs

Consider ease of filter changes, condensate removal, and access for servicing.

Installation and Best Practices

To get the most from an industrial air dryer dehumidifier:

Install in a central location with good airflow access.

Use proper ducting for intake and dry air delivery if required.

Regularly clean filters and inspect coils or desiccant media.

Monitor humidity trends and adjust settings as production demands change.

Routine maintenance ensures consistent performance and extends system lifespan.

Conclusion

An industrial air dryer dehumidifier is a vital component for any facility where humidity control impacts product quality, equipment longevity, or process stability. By removing excess moisture from the air and maintaining a controlled environment, these systems help manufacturers reduce waste, protect assets, and ensure reliable operational performance.

Whether you need general dehumidification for storage or precise moisture control for sensitive processes, choosing the right industrial air dryer dehumidifier can make a significant difference in efficiency and outcomes.