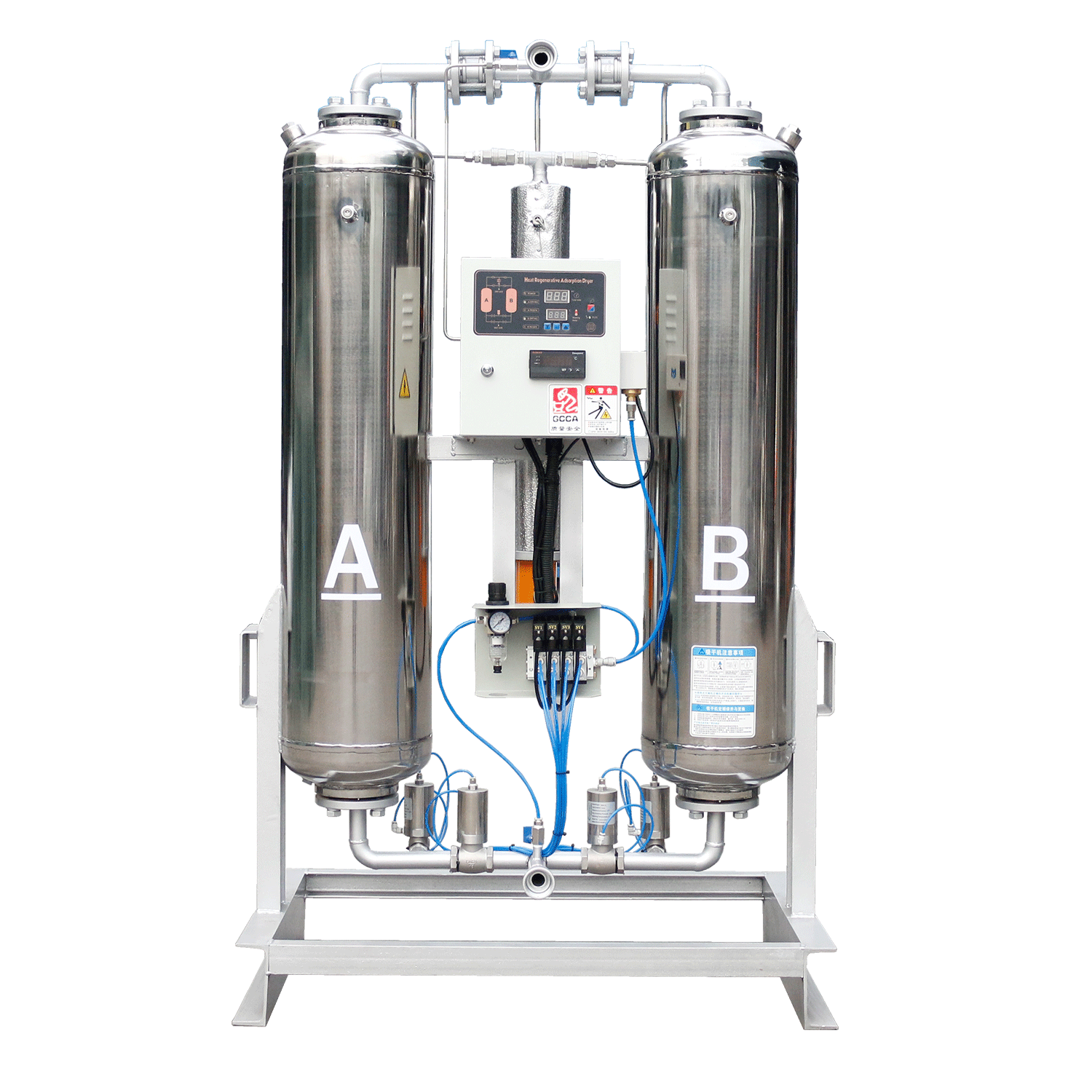

When selecting a stainless steel adsorption dryer, most users not only care about the technical data but also want to understand how it performs in real-world industrial environments, how it improves production quality, and how it reduces maintenance and energy costs. The 100HXS stainless steel adsorption dryer is designed precisely with these needs in mind.

1. Why Choose a Stainless Steel Adsorption Dryer?

Unlike traditional carbon steel or painted dryers, stainless steel adsorption dryers offer superior resistance to corrosion, oxidation, and chemical contamination.

This is crucial in industries where air purity and system hygiene are critical, such as:

Pharmaceuticals: Ensures that no rust particles or oil vapor enter medical production lines.

Food & Beverage: The smooth stainless-steel surface is easy to clean and sterilize, maintaining strict sanitary standards.

Electronics: Prevents corrosion of sensitive circuit boards and microchips.

Chemical & Petrochemical: Resists aggressive gases and solvents.

2. Working Principle Simplified

The 100HXS dryer combines PSA (Pressure Swing Adsorption) and TSA (Temperature Swing Adsorption) technologies.

This means it dries compressed air in two stages:

Adsorption phase: Moisture in the compressed air is captured by desiccant materials under pressure.

Regeneration phase: A portion of dry air or heat regenerates the adsorbent, readying it for the next cycle.

This process ensures a stable dew point between -20°C and -50°C, providing reliable dry air 24/7.

3. Key Advantages for Industrial Users

Durable & Long Service Life: Stainless steel structure extends the equipment’s operational lifespan.

Low Maintenance: Smooth internal surfaces prevent scale buildup, reducing cleaning frequency.

Energy Efficiency: Optimized airflow and regeneration design minimize purge gas loss.

Safety & Cleanliness: Ideal for cleanroom and GMP-compliant environments.

Customization: Available for both compressed air and nitrogen, adapting to specific industrial needs.

4. Installation and Maintenance Tips

To maintain optimal performance:

Ensure oil-free or low-oil air sources (≤0.1 ppm).

Keep the ambient temperature within 2–45℃.

Schedule regular checks for valve operation and desiccant condition.

Install pre-filters and after-filters to enhance system life.

Proper installation and regular preventive maintenance can extend service life by up to 30% and maintain stable dew point levels.

5. The Real Value in Modern Production

In today’s manufacturing environment, compressed air purity equals product reliability.

By choosing the 100HXS stainless steel adsorption dryer, factories ensure that:

Machinery runs efficiently with less downtime,

Products meet strict quality and hygiene standards, and

Operational costs are reduced through improved energy utilization.

Conclusion

The 100HXS Stainless Steel Adsorption Dryer is more than just a drying system—it’s an essential component in achieving high-quality, energy-efficient, and contamination-free production.

For industries that demand both performance and purity, stainless steel adsorption dryers deliver unmatched reliability and return on investment.