Introduction: Why You Need a 1130 SCFM Refrigerated Air Dryer

In any compressed air system, moisture is the enemy. Excess water vapor in compressed air can lead to corrosion, equipment failure, poor product quality, and system inefficiency. When managing high air volumes, a high-capacity solution is essential—and that’s where the 1130 SCFM refrigerated air dryer becomes a critical part of your system.

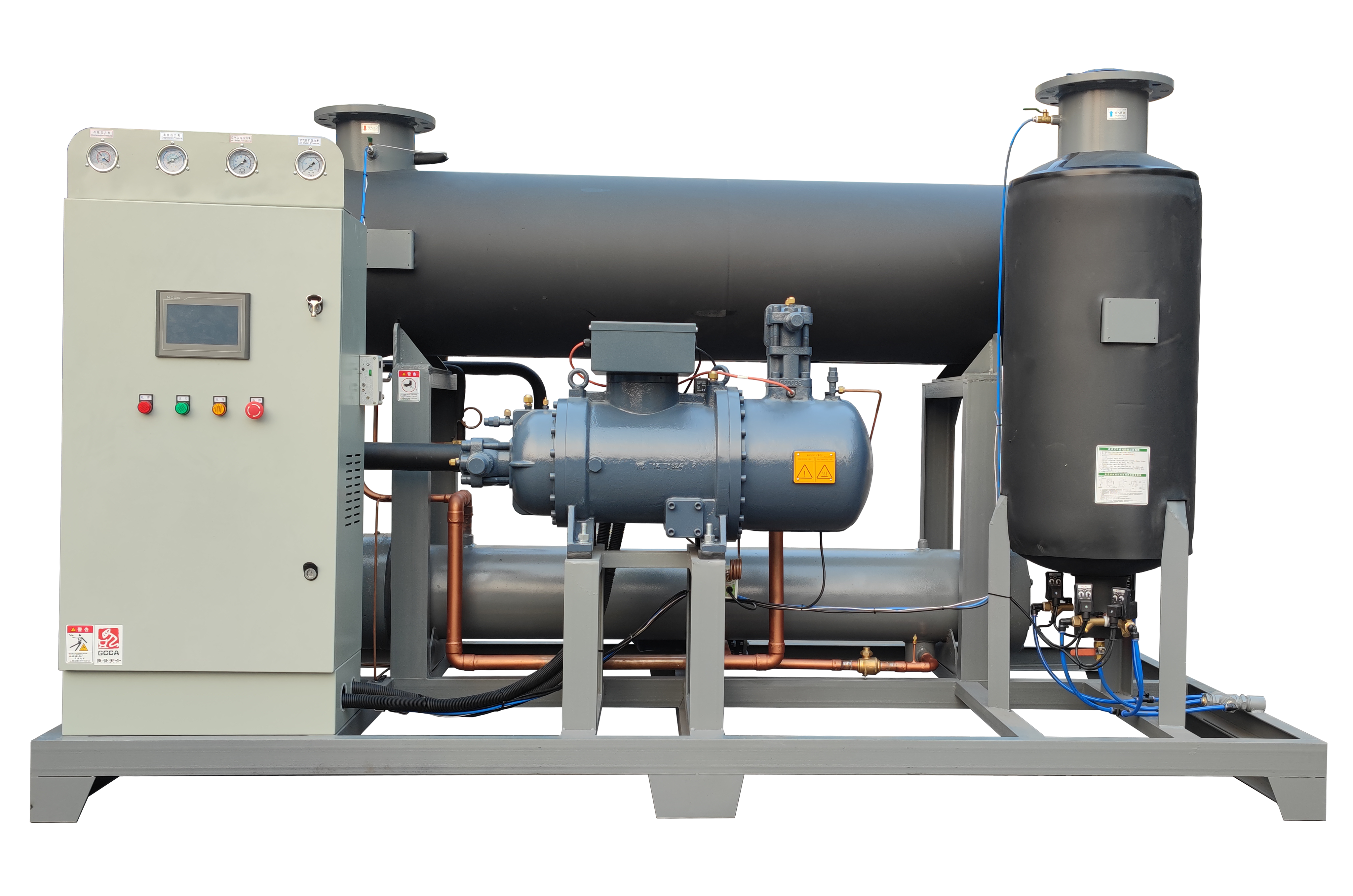

Built for heavy-duty industrial applications, a 1130 SCFM refrigerated air dryer efficiently removes moisture from compressed air at flow rates up to 1130 SCFM (Standard Cubic Feet per Minute). Whether you’re in manufacturing, food processing, automotive production, or CNC machining, this air dryer ensures consistent dew points, optimal air quality, and system longevity.

What Is a 1130 SCFM Refrigerated Air Dryer?

A 1130 SCFM refrigerated air dryer is a high-capacity, heat-exchange-based system that cools compressed air to near freezing, allowing water vapor to condense and be removed before the air enters downstream equipment.

Key Features:

✅ Capacity: Handles up to 1130 SCFM air flow

✅ Technology: Uses refrigeration cooling cycle

✅ Typical Dew Point: 35°F to 50°F (2°C to 10°C)

✅ Applications: Ideal for large-scale industrial systems

✅ Continuous Operation: Built for 24/7 environments

It ensures that even the largest compressed air systems operate with clean, dry air—improving efficiency and reducing wear and tear.

Key Benefits of the 1130 SCFM Refrigerated Air Dryer

✅ Stable Dew Point Performance

Maintain a consistent dew point under varying loads, ensuring that moisture is effectively removed in any condition.

✅ Corrosion & Rust Prevention

Dry air prevents pipe corrosion, control valve sticking, and damage to air-powered tools and machinery.

✅ Energy-Efficient Operation

Modern 1130 SCFM refrigerated air dryers use intelligent control systems to reduce power consumption and optimize refrigeration cycles.

✅ Easy Installation & Maintenance

Compact footprint and plug-and-play integration into existing systems make this model perfect for retrofits or new setups.

✅ Cost-Effective Protection

By preventing water-related failures, it reduces the total cost of ownership across your compressed air system.

Where Is the 1130 SCFM Refrigerated Air Dryer Used?

This powerful unit is ideal for:

Manufacturing Plants

Automotive Assembly Lines

Food & Beverage Processing Facilities

Pharmaceutical Manufacturing

Packaging & Printing Industry

Heavy Industrial Equipment Facilities

Technical Specifications (Sample)

| Specification | Value |

|---|---|

| Maximum Flow Capacity | 1130 SCFM |

| Dew Point | 35°F to 50°F (Pressure Dew Point) |

| Inlet Air Temperature Range | 35°F – 140°F |

| Ambient Temperature Range | 40°F – 115°F |

| Power Supply | 380V/1Ph/60Hz (customizable) |

| Connections | 2” NPT or Flanged |

| Dimensions (L x W x H) | 42” x 30” x 55” (example) |

| Weight | ~600 lbs (varies by model) |

🧊 Power Your System with Dry Air – Choose Our 1130 SCFM Refrigerated Air Dryer Today!

Maximize your compressed air performance with our high-efficiency 1130 SCFM refrigerated air dryer. Built for tough industrial environments, this dryer offers dependable performance, intelligent control, and long-term energy savings.

✅ Handles high-volume compressed air loads

✅ Eliminates water vapor, rust, and system blockages

✅ Reduces maintenance and downtime

✅ Plug-and-play installation with minimal supervision

👉 Don’t let moisture damage your productivity. Invest in reliability and performance today.

🛒 Get Your 1130 SCFM Air Dryer Now

How to Select the Right 1130 SCFM Refrigerated Air Dryer

When selecting a 1130 SCFM refrigerated air dryer, consider the following:

Actual Flow Rate Requirements: Confirm that your system really needs 1130 SCFM (or slightly less) to avoid oversizing.

Inlet Air Conditions: Temperature, humidity, and pressure can all affect dryer performance.

Installation Environment: Make sure ambient temperatures don’t exceed operating specs.

Power Source Compatibility: Choose a voltage and phase that suits your facility.

Aftercooler Integration: Use a pre-cooler if inlet temperatures are high (>100°F).

Maintenance Access: Ensure enough clearance for service tasks like drain checks and filter changes.

Maintenance Tips for Maximum Performance

Check Condensate Drains Weekly

Prevent water backup by ensuring drains are clear and automatic traps are functioning.Clean the Heat Exchanger Monthly

Dust and oil can reduce cooling efficiency—keep the surfaces clean.Replace Air Filters Regularly

Pre-filters and inline filters should be inspected and replaced based on usage.Monitor Dew Point Readings

Unexpected dew point shifts can indicate issues like refrigerant leakage or blocked airflow.

FAQ

What size air compressor does a 1130 SCFM dryer work with?

Typically, a 1130 SCFM refrigerated air dryer is used with compressors in the 150–200 HP range, depending on PSI and duty cycle.

Can it operate in continuous 24/7 production lines?

Yes, our 1130 SCFM dryers are engineered for continuous, heavy-duty operation in industrial environments.

How does it compare to a desiccant dryer?

Refrigerated dryers are more energy-efficient and economical for applications that don’t require ultra-low dew points (like -40°F). They are ideal for general industrial use.

Is the installation process complex?

Not at all. The unit arrives pre-tested and calibrated. Most installations take 2–4 hours, depending on site layout.

What certifications are available?

Models can be supplied with CE, ISO 9001, and UL-compliant options, depending on the market and your requirements.

Conclusion: Keep Your Air Clean, Dry, and Reliable with a 1130 SCFM Refrigerated Air Dryer

Investing in a 1130 SCFM refrigerated air dryer is essential for maintaining system integrity, product quality, and operational efficiency in large-scale compressed air systems. With advanced moisture removal capabilities, energy-saving features, and industrial-grade reliability, this dryer is your best defense against water-induced failures.

Ready to protect your air system from moisture damage? Choose a 1130 SCFM refrigerated air dryer engineered for performance and built to last.

Related products:

The 3885 CFM refrigerated air dryer (water cooled) is a high-capacity industrial solution designed for removing moisture from large-scale compressed air systems. Built for continuous and demanding operation, this water-cooled unit ensures a steady dew point and maximum system protection. Whether you're operating in petrochemical, steel, manufacturing, or pharmaceutical industries, the 3885 CFM refrigerated air dryer delivers superior drying performance and energy efficiency.

The 4238 CFM refrigerated air dryer (water cooled) is a high-capacity, industrial-grade dryer designed to eliminate moisture from large compressed air systems. Built with a powerful water-cooled refrigeration circuit, this dryer ensures reliable and continuous moisture removal with a stable pressure dew point. For industries that demand high airflow rates and dependable air quality, the 4238 CFM refrigerated air dryer (water cooled) is the ideal solution.

The 8830 CFM refrigerated air dryer (water cooled) is a top-tier industrial solution engineered to remove moisture from large-scale compressed air systems. Built for ultra-high capacity applications, this dryer ensures consistently dry air with a stable dew point and superior thermal control using an advanced water-cooled condenser system.