The 1340 SCFM Water Cooled Refrigerated Air Dryer is engineered for high-capacity, continuous-duty applications that demand stable, moisture-free compressed air.

While its key features—like high flow rate, efficient heat exchange, and reliable dew point control—are well recognized, professional users often want to go beyond specifications.

Here’s everything you should know to get the best performance, energy efficiency, and reliability out of your Lingyu 1340 SCFM refrigerated air dryer.

1. Installation Insights for Peak Performance

🧱 Location & Environment

Install Indoors: Choose a clean, dry, and ventilated indoor area to avoid corrosion and dust accumulation.

Water Supply Stability: Ensure the cooling water source maintains a temperature of ≤32°C (89.6°F).

Avoid Heat Interference: Keep the dryer away from boilers, compressors, or direct sunlight.

🔧 Piping & Connections

Water Circuit: Connect the cooling water inlet/outlet firmly with corrosion-resistant fittings. Maintain a flow rate between 80–100 L/min for optimal heat exchange.

Air Circuit: Use 3″ flanged pipes for air inlet/outlet; check airflow direction according to the machine labels.

Vibration Control: Mount the dryer on a stable base and use flexible connectors to reduce vibration and noise.

2. Energy Efficiency: How to Save Power and Water

The 1340 SCFM water-cooled dryer is already designed for lower power consumption compared to air-cooled types, but these tips can further reduce operating costs:

✅ Optimize Cooling Water Temperature: The system performs best with cooling water at 25–30°C — reducing compressor load and energy use.

✅ Maintain Flow Rate Consistency: Avoid sudden drops in water pressure; unstable flow can reduce cooling efficiency.

✅ Use Heat Recovery: In some setups, waste heat from the dryer can preheat water for other industrial processes.

✅ Schedule Maintenance Smartly: Clean condensers and filters regularly — clogged parts make the system work harder, wasting energy.

3. Routine Maintenance Guide

| Maintenance Task | Recommended Frequency | Key Steps |

|---|---|---|

| Drain System Check | Weekly | Ensure the automatic drain discharges properly to avoid condensate buildup. |

| Cooling Water Filter Cleaning | Monthly | Prevent scale or dirt accumulation in the water line. |

| Heat Exchanger Inspection | Every 6 months | Check for corrosion or scaling to maintain efficient cooling. |

| Refrigerant Check | Annually | Ensure no leakage and maintain stable dew point control. |

| Electrical System Audit | Annually | Inspect relays, wiring, and sensors for secure connection and safe operation. |

💡 Tip: Keep a simple maintenance logbook — recording water temperature, dew point, and drain cycle frequency can help predict service needs early.

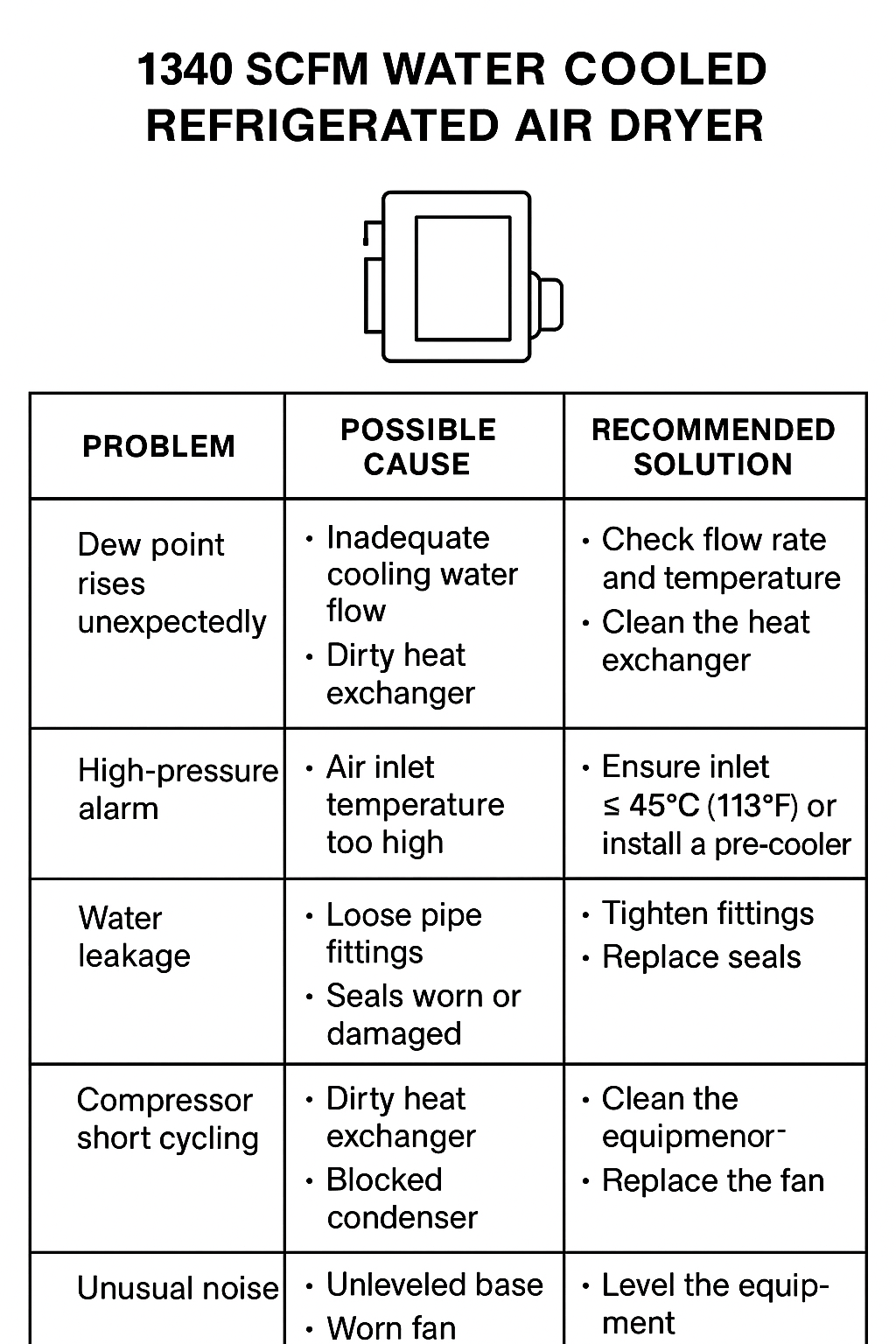

4. Common Problems & Quick Fixes

| Problem | Likely Cause | Recommended Action |

|---|---|---|

| Dew point rises unexpectedly | Inadequate cooling water flow | Check flow rate, temperature, or clean water filter |

| High-pressure alarm | Air inlet temperature too high | Ensure inlet ≤45°C or install pre-cooler |

| Water leakage | Loose pipe fittings | Tighten fittings or replace seals |

| Compressor short cycling | Dirty heat exchanger or blocked condenser | Clean exchanger and confirm refrigerant level |

| Abnormal vibration/noise | Unleveled base or worn fan bearings | Level equipment, replace worn parts |

5. Integration with Your Compressed Air System

For optimal system performance, consider pairing your dryer with:

Pre-Filters: Remove oil and particulates before the dryer.

Post-Filters: Deliver ultra-clean air downstream.

Condensate Separator: Automatically collects and discharges separated water.

Pressure Regulators: Maintain consistent air pressure to avoid overloading the dryer.

When combined, these components ensure your air system meets ISO 8573-1 air quality standards.

6. Suitable Applications

The 1340 SCFM water-cooled dryer is ideal for:

Heavy Manufacturing: Machine tools, assembly lines, and pneumatic systems.

Chemical & Petrochemical Industries: Sensitive processes that demand ultra-dry air.

Food & Beverage Production: Hygienic, contaminant-free compressed air.

Automotive Manufacturing: Painting and air tool applications.

Facilities with Cooling Water Infrastructure: Maximize energy savings using existing chilled-water systems.

7. Upgrade Options & Customization

Lingyu supports a variety of upgrade features to match your plant requirements:

PLC or Touchscreen Control Systems for real-time monitoring of dew point and pressure.

Remote Monitoring integration for plant automation systems (e.g., Modbus or Ethernet).

Custom Voltage and Connection Sizes for international installations.

OEM/ODM Branding for partners requiring customized labeling or panel design.

8. Environmental Commitment

The 1340 SCFM refrigerated air dryer uses R407C or R134a refrigerants — both eco-friendly and compliant with international standards.

By optimizing water-cooled efficiency, this system minimizes energy waste and supports sustainable industrial operations.

9. Summary

The Lingyu 1340 SCFM Water Cooled Refrigerated Air Dryer provides an exceptional balance between high flow capacity, cooling performance, and energy efficiency.

With proper installation, maintenance, and system integration, you can expect years of reliable, continuous operation — even in demanding industrial environments.

For more product information:

The 1340 SCFM refrigerated air dryer (water cooled) is a high-performance moisture removal system designed for industrial applications that demand clean and dry compressed air. Engineered for reliability and efficiency, this water-cooled model uses chilled water circulation to condense and remove moisture from compressed air streams with a rated capacity of 1340 SCFM.