The 200 CFM Refrigerated Air Dryer (Air Cooled) stands out for its robust design, energy efficiency, and reliable dew point control. But beyond the key features and specifications, professional users often want to understand how to get the best long-term performance, save energy, and integrate the dryer into their specific systems.

This article dives deeper into what real-world users truly care about.

1. Installation & Setup Tips for Optimal Efficiency

📍 Placement & Ventilation

Allow Space Around the Unit: Keep at least 30–50 cm clearance from walls and other equipment for proper air circulation.

Avoid Heat & Dust: Install the dryer in a clean, well-ventilated indoor area — high dust levels can reduce cooling efficiency and clog filters.

Stable Surface: Place the dryer on a level surface to minimize vibration and noise during operation.

🔧 Piping & Connection

Use Pre- and Post-Filters: Installing filters before and after the dryer ensures clean, particle-free air and prolongs the life of the refrigeration system.

Avoid Long or Sharp Bends: Short, straight piping reduces pressure drop and keeps the airflow consistent.

Check Flow Direction: Always connect the inlet and outlet according to the arrows on the dryer panel.

2. Energy-Saving Best Practices

Energy efficiency isn’t just about hardware — it’s about how you operate it.

Match Dryer Capacity to Compressor Output: Operating far below or above rated capacity (200 CFM) can waste power or reduce performance.

Clean the Condenser Regularly: Dust and dirt on the condenser fins increase power consumption by up to 15%.

Maintain Optimal Room Temperature: Operating between 20–30°C (68–86°F) yields the highest cooling efficiency.

Use an Automatic Drain System: This unit’s auto-drain feature reduces manual intervention and minimizes air loss, saving energy over time.

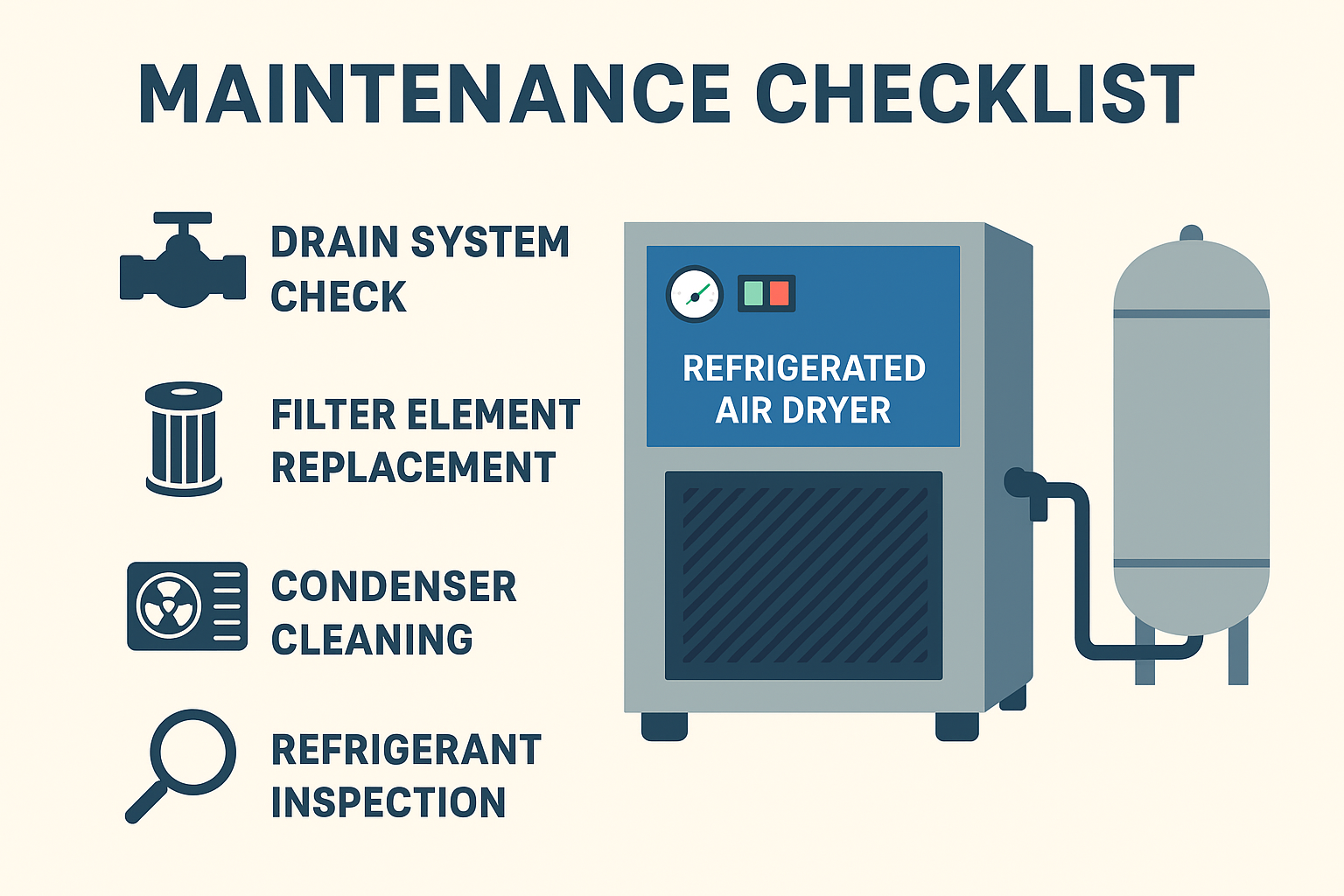

3. Routine Maintenance Checklist

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Drain System Check | Weekly | Ensure no blockage or water buildup |

| Filter Element Replacement | Every 3–6 months | Maintain air purity and avoid internal corrosion |

| Condenser Cleaning | Every 6 months | Keep airflow unobstructed for stable cooling |

| Refrigerant Inspection | Annually | Check for leaks and maintain dew point accuracy |

| Electrical Connection Check | Annually | Prevent short circuits or contact wear |

💡 Pro Tip: Keeping a maintenance log helps track efficiency trends and anticipate service needs before performance drops.

4. Troubleshooting Common Issues

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Moisture in outlet air | Inlet air too hot or flow exceeds 200 CFM | Reduce inlet temperature or flow rate |

| High dew point | Dirty condenser or insufficient ventilation | Clean condenser, check fan operation |

| Frequent compressor cycling | Ambient temperature too high | Improve room ventilation or relocate unit |

| Unusual noise | Loose mounting or worn fan bearings | Tighten components, replace fan if needed |

5. Choosing the Right Dryer for Your System

When selecting an air dryer, consider these three parameters:

Air Flow (CFM): Match or slightly exceed your compressor’s output.

Ambient Temperature: Air-cooled models perform best in environments below 45°C (113°F).

Required Dew Point: For most manufacturing applications, 2–10°C (35.6–50°F) is sufficient.

If your system operates in humid or high-temperature environments, Lingyu engineers can recommend custom configurations or hybrid air-water cooling designs to ensure consistent results.

6. Integration with Other Air Treatment Systems

To achieve ISO 8573-compliant air quality, pair your 200 CFM air dryer with:

Coalescing Pre-Filter: Removes oil and particles before entering the dryer.

Activated Carbon Post-Filter: Ensures ultra-clean, odor-free output.

Condensate Separator: Collects and automatically discharges condensed water.

These accessories not only protect your dryer but also ensure optimal downstream equipment performance.

7. Advanced Options & Upgrades

Smart Control System: Optional PLC or touchscreen controller for monitoring dew point, power consumption, and alarm status.

Remote Monitoring Interface: Integrate the dryer with your plant’s control system for real-time diagnostics.

Customized Voltage & Connections: Support for international standards — 110V/220V/380V, 50/60Hz, and metric or imperial fittings.

8. Environmental Responsibility

The 200 CFM refrigerated air dryer uses R134a or R410A refrigerants, which comply with global environmental standards. Lingyu is committed to developing eco-friendly systems that balance performance, reliability, and sustainability.

9. Real-World Application Stories

Automotive Workshop (Thailand): Improved spray painting quality and tool performance by eliminating moisture contamination.

Food Packaging Plant (Vietnam): Reduced product rejects by maintaining dry, hygienic compressed air.

CNC Machining Center (Indonesia): Extended equipment lifespan and minimized downtime through stable dew point control.

10. Conclusion

The Lingyu 200 CFM Refrigerated Air Dryer (Air Cooled) isn’t just a piece of equipment — it’s a key component of a clean, reliable compressed air system.

By following proper installation, maintenance, and operation practices, users can expect years of stable, energy-efficient performance.

Ready to take your compressed air system to the next level?

📩 Contact Lingyu today for expert consultation, system design advice, or a customized quotation.

For more product information:

The 200 CFM refrigerated air dryer (air cooled) is a compact and efficient solution for removing moisture from compressed air systems. Designed for mid-sized industrial applications, this dryer ensures clean, dry air to protect downstream equipment from corrosion, contamination, and failure.