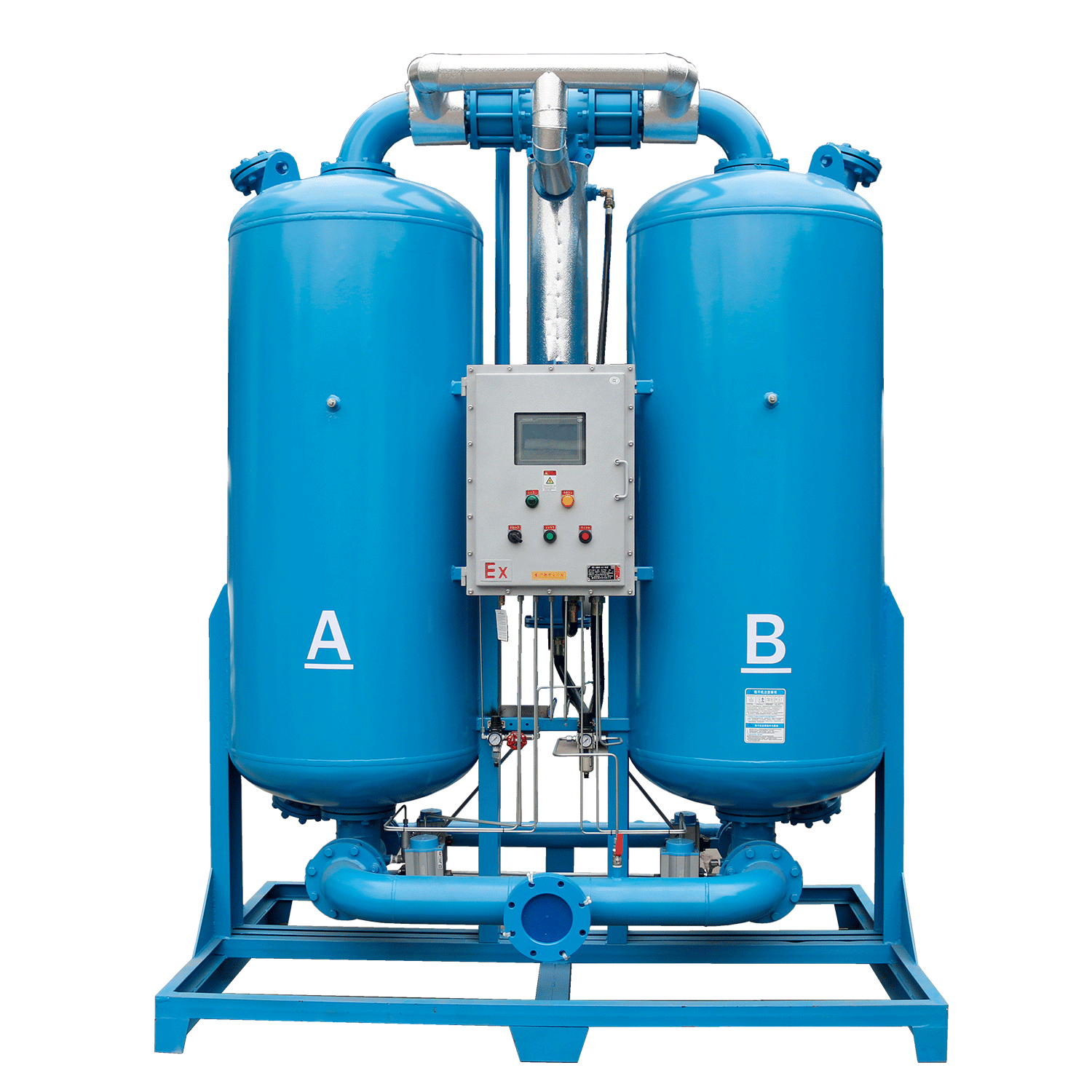

The 600HX Explosion-Proof Adsorption Dryer is designed for high-risk industrial environments where flammable gases or explosive dust may be present. While the technical specifications detail performance, capacity, and conditions, many users are most concerned with safety standards, selection criteria, installation guidance, and long-term reliability.

1. How Explosion-Proof Adsorption Dryers Work

The 600HX dryer combines Pressure Swing Adsorption (PSA) and Temperature Swing Adsorption (TSA) technologies to remove moisture from compressed air under variable pressure and temperature conditions.

Key design features include:

Explosion-proof electrical components certified to ATEX/IECEx standards.

Anti-static materials to prevent spark generation.

Temperature control system to prevent overheating.

Special sealing and grounding to ensure airtight, spark-free operation.

By using these safety mechanisms, the dryer can continuously deliver air with a dew point of ≤ -40°C, even in hazardous zones.

2. Where Explosion-Proof Dryers Are Most Needed

Explosion-proof dryers are vital in any facility handling volatile gases, vapors, or dust. The 600HX model is widely used in:

Petroleum & Chemical Industry: For gas separation, refining, and chemical synthesis processes.

Mining & Metallurgy: To dry compressed air in environments with combustible gases.

Pharmaceutical Manufacturing: To ensure sterile, dry air for cleanroom and tablet coating processes.

Paint & Coating Industry: To prevent solvent vapor ignition during spray and curing operations.

Food & Beverage Production: Especially in powder handling and packaging areas.

Textile Industry: To prevent static discharge in fiber processing.

Military & Aerospace: For secure compressed air in ammunition manufacturing or testing environments.

3. Safety Certifications and Compliance

Explosion-proof dryers must comply with international safety standards. The 600HX dryer can be built to meet:

ATEX Directive (EU): For explosive atmospheres (Zone 1, Zone 2).

IECEx Certification: Global compliance for electrical safety.

National Safety Standards (GB, NEC, etc.): Depending on installation region.

IP-rated Enclosures: To resist dust and moisture ingress.

Tip: Always confirm your site’s classified zone (e.g., Zone 1 or Zone 2) before selecting a dryer to ensure proper protection level.

4. Installation & Maintenance Tips

Proper installation and care are crucial for maintaining both safety and performance:

Install in a ventilated area: Maintain airflow to prevent heat buildup.

Check grounding regularly: Ensure all static charges are safely discharged.

Use certified explosion-proof accessories: Including wiring, connectors, and control panels.

Regularly inspect seals and adsorbents: Replace damaged components promptly.

Monitor dew point and pressure loss: To detect early signs of system inefficiency.

Train operators: Personnel should be familiar with explosion-proof handling protocols.

5. Energy Efficiency and Operation Optimization

Even with safety as the top priority, the 600HX dryer is designed for energy-efficient performance:

Optimized regeneration control: Reduces purge air use to as low as 3.5% of total flow.

Cycle time adjustment (90–240 min): Allows flexible regeneration according to system load.

High-efficiency adsorbents: Activated alumina and molecular sieves ensure stable dew points and long service life.

Low pressure drop (≤0.2 bar): Minimizes system energy loss.

6. Why Choose Lingyu 600HX Explosion-Proof Dryer

Lingyu dryers provides a full range of explosion-proof compressed air solutions beyond just standard dryers:

Custom engineering: Designed for specific gas, temperature, and zone classifications.

Full compliance: Meets global safety standards including ATEX and IECEx.

Integrated air treatment systems: Filters, separators, and gas purification available.

Global service support: OEM/ODM capability and responsive after-sales assistance.

Conclusion

The Lingyu 600HX Explosion-Proof Adsorption Dryer is more than a drying system — it’s a critical safety component for industries working in hazardous environments. With advanced PSA+TSA drying technology, certified explosion-proof protection, and high efficiency, it ensures both air purity and operational safety in the most demanding applications.

Whether used in chemical plants, oil refineries, or aerospace facilities, the 600HX is built to deliver reliable, dry, and safe compressed air 24/7.

For more product information:

2. Resists chemical corrosion and extends service life

3. Special sealing technology prevents flammable gases or dust from entering theinterior of the machine

4. Regeneration gas consumption can be adjusted, with energy saving and dewpoint adjustment function