A compressed air dryer system is an essential part of any industrial compressed air setup. Its main purpose is to remove moisture from compressed air, ensuring high-quality, dry air for downstream equipment, tools, and processes. Without a compressed air dryer system, excess water vapor can cause corrosion, product defects, and costly downtime.

In this guide, we’ll explore how a compressed air dryer system works, the main types available, factors affecting its performance, and tips to keep it running efficiently.

Why a Compressed Air Dryer System is Essential

When air is compressed, the moisture it contains becomes concentrated. If not removed, this water can:

Corrode pipes, valves, and tanks

Damage pneumatic tools and automation equipment

Contaminate products in food, pharmaceutical, and electronics industries

Cause blockages in air lines during freezing conditions

A compressed air dryer system prevents these problems by reducing the moisture content to a safe level, measured as dew point.

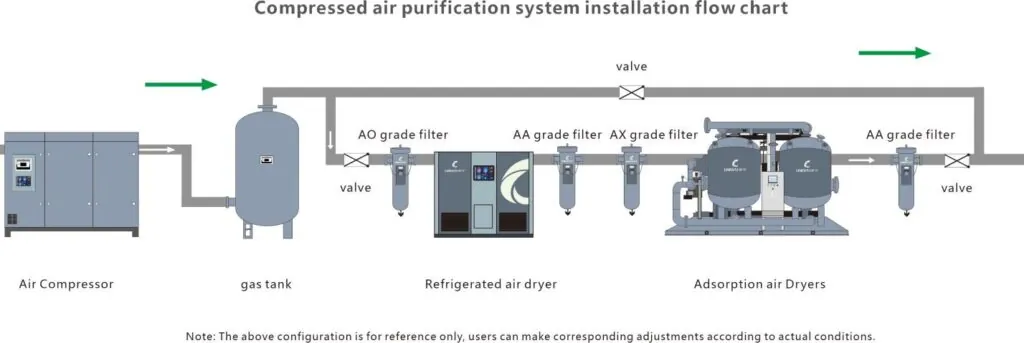

How a Compressed Air Dryer System Works

A compressed air dryer system works by lowering the temperature of compressed air or using special materials to absorb moisture. The most common steps include:

Air Intake – Compressed air enters the dryer carrying water vapor.

Moisture Removal – Cooling or adsorption condenses and separates water.

Filtration – Particles and oil aerosols are removed.

Reheating or Discharge – Dry air is sent downstream for use.

Types of Compressed Air Dryer Systems

1. Refrigerated Compressed Air Dryer System

Uses a refrigeration cycle to cool air, condense moisture, and remove it.

Typical dew point: 3°C–5°C (37°F–41°F).

Best for general industrial use.

2, Low pressure drop: the pressure loss of the whole machine is less than0.015MPa, which is lower than the national standard;

3, Low dew point: under standard working conditions, the pressure dew point isas low as 2~10'C, and the electronic bypass valve is adopted, making thesystem more stable,

2. Desiccant Compressed Air Dryer System

Uses an adsorbent material to trap moisture molecules.

Can reach dew points as low as -40°C (-40°F).

Suitable for sensitive processes like pharmaceuticals or electronics.

Integrated design: small footprint, easy to install, after years of technical research, modern technology and equipment production, each product is strictly tested to meet the use of standards before leaving the factory.

3. Membrane Compressed Air Dryer System

Uses semi-permeable membranes to separate water vapor from air.

Compact and low-maintenance.

Ideal for point-of-use drying.

2, Rated inlet pressure: 0.7MPa (0.6MPa~1.0MPa is allowed,other pressure levelsare available for customization)

3. Rated inlet temperature: 10'C~30°C (imit inlet temperature: ≤40°C)

4. Inlet air dew point: <15°C

5. Outlet pressure dew point: <-20'℃ (-40'C optional)

Key Benefits of a Compressed Air Dryer System

Protects Equipment – Prevents rust and wear in pneumatic tools.

Improves Product Quality – Keeps manufacturing processes free of moisture contamination.

Reduces Downtime – Prevents unexpected failures caused by water damage.

Extends System Life – Minimizes corrosion inside air lines.

Factors That Affect Compressed Air Dryer System Performance

Inlet Air Temperature – Higher temperatures increase moisture load.

Ambient Humidity – Humid climates require more drying capacity.

Air Flow Rate – Exceeding rated capacity can reduce dryer efficiency.

Maintenance Practices – Dirty filters or clogged drains increase dew point.

Maintenance Tips for a Compressed Air Dryer System

Clean Heat Exchangers – Prevents reduced cooling efficiency.

Inspect Filters – Replace clogged filters to maintain airflow.

Check Drains – Ensure condensate drains are working properly.

Monitor Dew Point – Use sensors for real-time performance tracking.

Service Regularly – Follow manufacturer’s service intervals.

Applications of a Compressed Air Dryer System

Manufacturing – Protects pneumatic tools and automation systems.

Food & Beverage – Ensures air purity for product safety.

Pharmaceuticals – Prevents contamination during production.

Automotive – Maintains paint finish quality.

Electronics – Prevents short circuits from moisture.

FAQ – Compressed Air Dryer System

What is the ideal dew point for a compressed air dryer system?

For general use, 3°C (37°F) is sufficient; for sensitive industries, -40°C may be required.

How often should a compressed air dryer system be serviced?

Most systems need service every 6–12 months, depending on usage.

Can I run a compressed air system without a dryer?

Yes, but it increases the risk of corrosion, equipment failure, and product defects.

What size compressed air dryer system do I need?

Match the dryer’s capacity to your compressor’s maximum flow rate and operating conditions.

Do I need both a filter and a dryer?

Yes, filters remove particles and oil, while the dryer removes moisture.

Conclusion

A compressed air dryer system is a crucial component of any compressed air setup. It ensures that moisture is removed efficiently, protecting both equipment and product quality.

By choosing the right type of compressed air dryer system and following proper maintenance practices, you can ensure reliable, long-lasting, and cost-effective operation. Whether you are in manufacturing, food processing, pharmaceuticals, or automotive industries, investing in a high-quality compressed air dryer system is essential for productivity and efficiency.