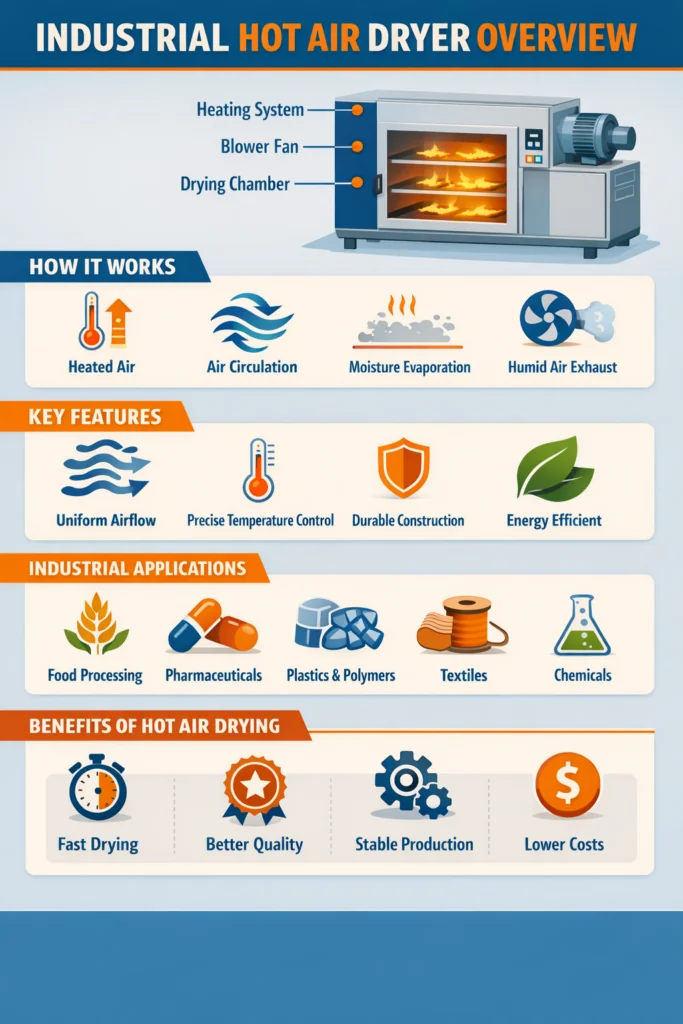

An industrial hot air dryer is a widely used drying system designed to remove moisture from materials through controlled hot air circulation. It plays a critical role in manufacturing processes where stable moisture control, consistent quality, and high production efficiency are required. From food processing to plastics, chemicals, and textiles, hot air dryers remain one of the most reliable and versatile industrial drying technologies.

What Is an Industrial Hot Air Dryer?

An industrial hot air dryer is a machine that uses heated air combined with forced airflow to evaporate and remove moisture from products or raw materials. Unlike natural or ambient drying, hot air drying significantly shortens drying time and ensures uniform results.

Typical components include:

Heating system (electric, gas, or steam)

High-efficiency blower or fan

Insulated drying chamber

Temperature and airflow control system

By precisely controlling temperature and air movement, industrial hot air dryers deliver repeatable and stable drying performance.

How an Industrial Hot Air Dryer Works

The drying process follows a simple but effective principle:

Ambient air is heated to a preset temperature

Hot air is circulated evenly across the material surface

Moisture evaporates due to heat transfer

Humid air is discharged or partially recirculated

This process continues until the desired moisture level is reached. Proper airflow design ensures that products dry evenly without overheating or deformation.

Key Features of Industrial Hot Air Dryers

Industrial hot air dryers are engineered for continuous operation in demanding environments. Common features include:

Uniform Air Distribution

Optimized airflow paths ensure consistent drying across all materials, reducing quality variations.

Accurate Temperature Control

Digital or PID temperature control allows precise adjustment for heat-sensitive materials.

Durable Industrial Construction

Heavy-duty insulation and corrosion-resistant materials support long service life.

Energy-Efficient Design

Heat insulation and optional air recirculation help reduce energy consumption.

Flexible Configurations

Available as cabinet dryers, tunnel dryers, conveyor dryers, hopper dryers, or customized systems.

Benefits of Using an Industrial Hot Air Dryer

Choosing an industrial hot air dryer brings several operational advantages:

Faster Drying Cycles

Hot air significantly accelerates moisture evaporation.Improved Product Quality

Uniform drying prevents cracking, warping, and moisture-related defects.Stable Production Output

Reliable drying reduces downtime and process variability.Lower Operating Costs

Efficient heat utilization minimizes wasted energy.Wide Application Range

Suitable for solids, powders, pellets, sheets, and coated products.

Common Industrial Applications

Industrial hot air dryers are used across many industries:

Food Processing

Drying grains, fruits, vegetables, spices, and food ingredients to extend shelf life.

Pharmaceuticals

Moisture removal for powders, granules, and tablets to ensure formulation stability.

Plastics & Polymers

Pre-drying plastic pellets and resins before injection molding or extrusion.

Textiles

Drying fabrics after washing or dyeing to improve finish quality.

Chemicals

Drying chemical powders, pigments, and intermediates while maintaining material integrity.

How to Choose the Right Industrial Hot Air Dryer

Selecting the right dryer depends on several key factors:

Material Characteristics

Moisture content, particle size, and heat sensitivity all influence dryer selection.

Required Drying Capacity

The dryer must match your production volume to avoid bottlenecks.

Temperature Range

Ensure the system can operate safely within your process temperature limits.

Energy Efficiency

Well-insulated designs and optimized airflow reduce long-term costs.

Automation Level

Advanced controls help achieve consistent and repeatable drying results.

Product Recommendations:

The independently developed EBZ200-2 multi-core driver can save more than 10% of the comprehensive energy consumption compared with the fixed cycle mode;

The optional dew point energy-saving control can extend the adsorption time and reduce the comprehensive energy consumption by more than 30% under load fluctuation conditions;

The communication can meet the user’s requirements such as RS-485 (standard), IoT connection, etc.

The optional dew point energy-saving control can extend the adsorption time and reduce the comprehensive energy consumption by more than 30% under load fluctuation conditions;

Customized high-performance adsorbent, 20% filling margin;

Installation and Maintenance Tips

To ensure long-term performance:

Install the dryer in a well-ventilated area

Ensure proper exhaust or moisture discharge

Regularly inspect heaters, fans, and airflow paths

Clean filters and air ducts to maintain efficiency

Monitor temperature and safety protection systems

Routine maintenance helps prevent uneven drying and extends equipment lifespan.

Conclusion

An industrial hot air dryer is a proven and efficient solution for moisture removal in industrial production. Its ability to deliver fast, uniform, and controllable drying makes it suitable for a wide range of materials and industries. With the right configuration and proper operation, a hot air dryer can significantly improve product quality, production efficiency, and overall process reliability.