The Lingyu 25/35/50 CFM refrigerated air dryers (air-cooled type) are favored by users of small to medium compressed air systems due to their compact design and high efficiency. Beyond product specifications and basic functions, users often want to know how to operate the equipment efficiently, maintain it properly, and extend its service life. This guide provides a comprehensive overview.

1. Efficient Usage Guidelines

1.1 Installation Location and Environment

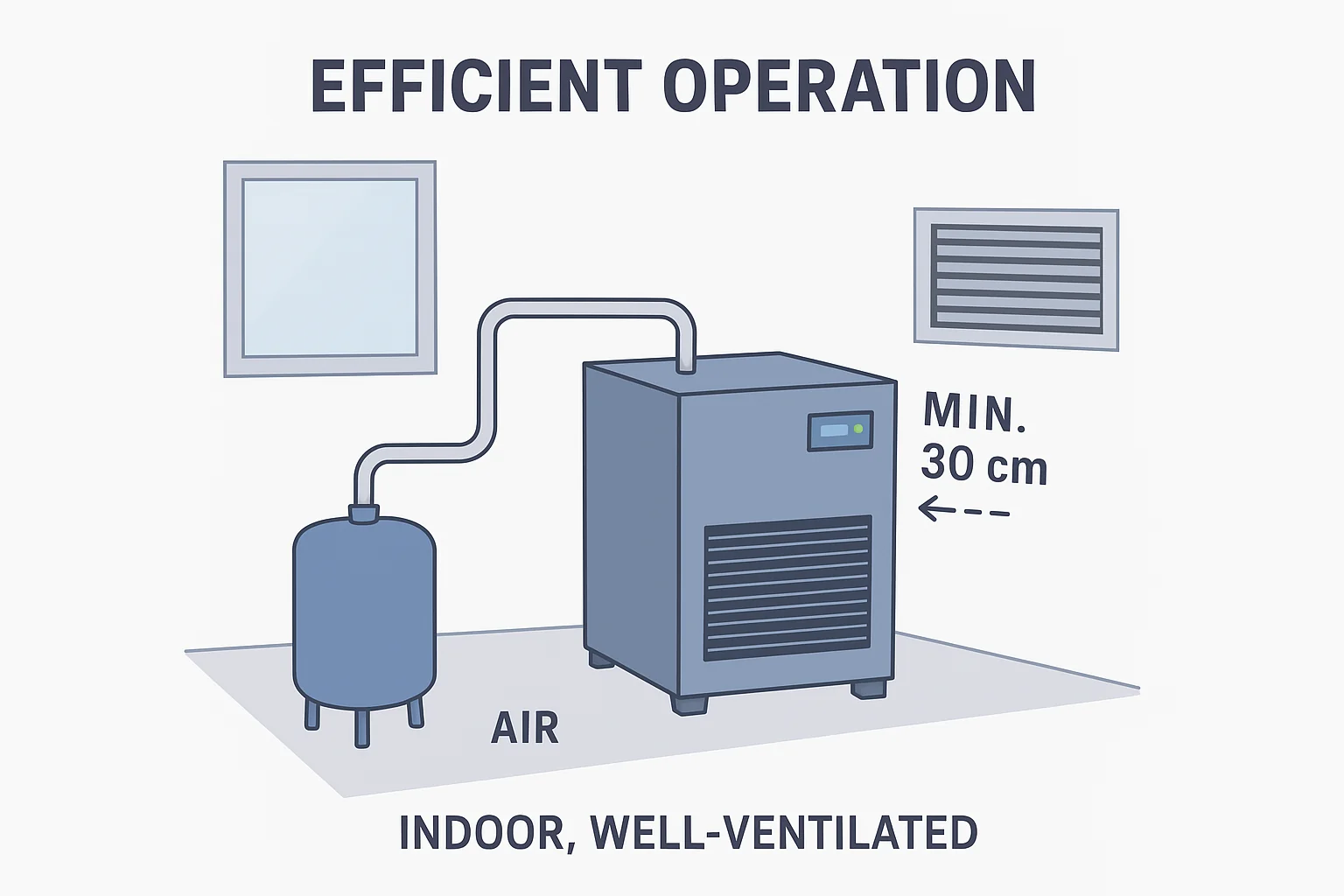

Indoor ventilation: Install in a well-ventilated indoor area, avoiding high temperatures or direct sunlight.

Distance from walls: Maintain at least 30–50 cm of space at the back and sides to ensure proper airflow.

Avoid dust: Install in a clean environment to reduce filter clogging and improve drying efficiency.

1.2 Inlet and Outlet Requirements

Inlet pressure: 4–10 bar (58–145 psi)

Inlet temperature: ≤ 45°C (113°F)

Recommended filters: Install a compressed air filter both before and after the dryer to effectively extend its service life.

1.3 Supporting Equipment Recommendations

Air receiver tank: Install an appropriately sized air receiver before the dryer to stabilize airflow and reduce pressure fluctuations.

Piping layout: Keep piping short and straight, minimizing elbows and resistance to improve airflow efficiency.

2. Energy-Saving Operation Tips

Maintain stable operating pressure: Keep within the recommended pressure range to avoid overloading the refrigeration system.

Regularly clean airflow paths: Keeping fins and fans clean enhances cooling efficiency and reduces energy consumption.

Choose appropriate capacity: Select the 25, 35, or 50 CFM model according to actual air consumption to avoid energy waste from oversized units running under low load.

Optimize intermittent shutdowns: During non-peak periods, short-term shutdowns combined with an air receiver can save energy without affecting production.

3. Daily Maintenance and Care

| Maintenance Item | Recommended Interval | Key Points |

|---|---|---|

| Automatic drain valve check | Weekly | Ensure smooth drainage; no water accumulation or blockage |

| Inlet and outlet filter replacement | Every 3–6 months | Prevent dust clogging and maintain air quality |

| Fin cleaning | Every 6 months | Use compressed air or a soft brush to remove dust |

| Refrigerant check | Annually | Performed only by professionals to ensure cooling efficiency |

| Electrical connections check | Annually | Ensure no loose or aged connections to prevent safety hazards |

Tip: Maintain a regular maintenance log to detect abnormalities early and extend equipment lifespan.

4. Common Issues and Solutions

Q1: Why is there still water in the outlet air?

Possible cause: Inlet air temperature too high or airflow exceeds rated value.

Solution: Install a cooler or reduce airflow to operate within rated conditions.

Q2: What to do if fan or compressor noise increases?

Possible cause: Dust accumulation or bearing wear.

Solution: Clean fins and fans; if noise persists, contact after-sales for bearing inspection.

Q3: What if the refrigeration system frosts?

Possible cause: Excessive air humidity or ambient temperature too low.

Solution: Reduce inlet humidity or maintain ambient temperature ≥ 5°C.

Q4: Can I replace the refrigerant myself?

Recommendation: Refrigerant handling must be performed by professionals to avoid leaks and safety risks.

5. Usage Case Examples

Small auto repair shop: After installing the 35 CFM model, spray systems and pneumatic tools saw a 20% increase in service life.

Laboratory gas supply system: Using the 25 CFM model ensured stable air drying for chromatographs and analyzers without condensation issues.

Lightweight packaging production line: The 50 CFM model with automatic drain valve reduced downtime for drainage and improved production efficiency.

6. Extended Recommendations

Comprehensive air treatment solutions: Combine filters, adsorption dryers, and piping monitoring for higher-quality compressed air supply.

Smart monitoring upgrades: Add pressure, temperature, and dew point sensors for critical equipment to enable remote monitoring and early warnings.

Customized requirements: Lingyu offers voltage, fitting, and panel customization to meet different operating conditions and regional requirements.

For more product information:

The 25/35/50 CFM Air-Cooled Refrigerated Air Dryer from Lingyu is a compact and energy-efficient solution for small to medium compressed air systems. It efficiently removes moisture and maintains a stable dew point, providing clean, dry air for tools, machinery, and production processes.