Technical Insight: Understanding the Low Air Consumption Blast Heating Adsorption Dryer

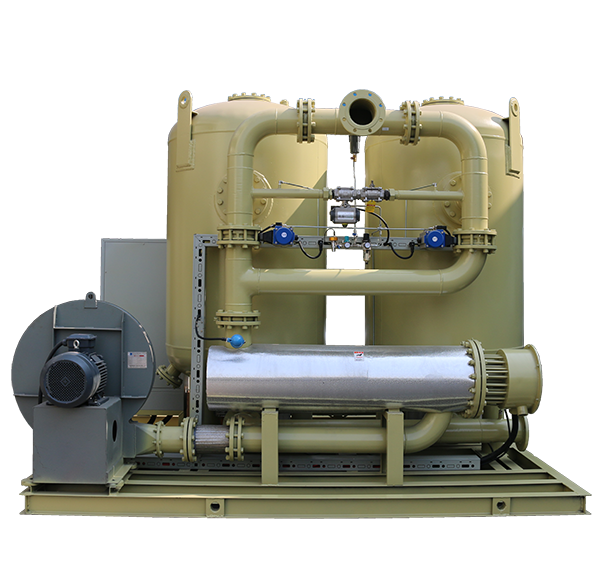

In industrial compressed air systems, achieving ultra-dry air while minimizing energy consumption is critical for equipment protection, process stability, and operational efficiency. The Low Air Consumption Blast Heating Regeneration Adsorption Dryer offers a zero-compressed-air consumption regeneration process with enhanced energy efficiency, reliability, and precise dew point control.

This article provides a deeper understanding of its working principle, performance advantages, and practical considerations for installation and maintenance.

How the Low Air Consumption Blast Heating Adsorption Dryer Works

The dryer builds upon micro-gas-consumption blast heat technology, adding an intermediate cooler to improve regeneration efficiency. Ambient air is drawn in by a blower and heated via a heater to regenerate the adsorbent, which desorbs moisture.

During the cooling stage, hot air passes through the intermediate cooler and the regeneration tower in a closed-loop circulation, maintaining consistent regeneration without consuming compressed air. This approach ensures minimal energy usage while providing a stable outlet pressure dew point of -20°C or -40°C (optional).

Technical Benefits and Performance Factors

1. Ultra-Low Air Consumption

By eliminating the need for compressed air during the regeneration cycle, the system reduces air waste, making it highly energy-efficient for continuous or large-scale operations. Regeneration gas consumption is limited to 2–3%, lowering operating costs.

2. Stable Dew Point Performance

The closed-loop blast heat system maintains a reliable outlet dew point, protecting downstream equipment, pneumatic tools, and sensitive instruments from moisture-related damage.

3. Wide Flow Capacity Range

The series supports flow capacities from 13.5 m³/min to 260 m³/min, accommodating small-scale laboratories to large industrial plants. Custom solutions are available for flows exceeding 260 m³/min or special temperature/material requirements.

4. High Ambient Temperature Tolerance

Rated for ambient temperatures up to 40°C, the dryer performs reliably under variable plant conditions, making it suitable for environments with high thermal loads.

5. Intelligent and Continuous Operation

Advanced control systems monitor regeneration, airflow, and temperature, providing alarms and diagnostics to reduce downtime and simplify maintenance. The intermediate cooler ensures consistent regeneration efficiency across long operating cycles.

Installation and Maintenance Recommendations

Fluid Compatibility: Suitable for compressed air and non-corrosive gases.

Rated Pressure: Typically 0.7 MPa (0.6–1.0 MPa customizable).

Inlet Air Requirements: Temperature 10–30°C, dew point ≤25°C.

Cooling Water: Ensure stable supply for optimal performance; recommended ambient temperature ≤35°C.

Maintenance: Regular inspection of filters, control systems, and cooling lines ensures continuous reliability.

Custom Specifications: Contact technical experts for specialized requirements exceeding 260 m³/min or unusual temperature/material needs.

Recommended Application Scenarios

The Low Air Consumption Blast Heating Adsorption Dryer is ideal for industries and systems requiring ultra-dry, energy-efficient compressed air, including:

Laboratory & Analytical Equipment: Gas chromatographs, ozone generators, FTIR spectrometers

Medical & Dental Applications: Dental compressors, medical air systems

Industrial Automation & Robotics: Pneumatic actuators, robotic machinery, air bearings

Environmental & HVAC Systems: Drying environmental chambers, outdoor control systems

Precision Manufacturing: Electronic chip testing, graphic printing, waveguide drying

Specialized Systems: Air-operated pumps, CEMS systems, car wash controls, bus doors/locks

Its versatile design ensures reliable operation across laboratories, medical facilities, manufacturing plants, and industrial automation setups.

Key Technical Insights for Buyers

Flow Capacity: Select a model according to peak air demand and anticipated future expansion.

Inlet Air Quality: Maintain inlet dew point and temperature within rated limits to ensure consistent performance.

Cooling & Circulation: Proper intermediate cooler operation is essential for efficient adsorbent regeneration.

Maintenance Access: Provide sufficient space for inspection and replacement of filters and control components.

Expert Conclusion

The Low Air Consumption Blast Heating Regeneration Adsorption Dryer offers energy-efficient, ultra-dry air with minimal compressed air usage. Its closed-loop regeneration system, intelligent controls, and wide capacity range make it ideal for industrial, laboratory, and medical applications requiring reliable and precise moisture control.

For facilities seeking high-performance, low-energy, continuous-operation dryers, this system provides a durable, cost-effective, and environmentally conscious solution.

For more product information

2. The independently developed EBZ200-2 multi-core driver can save more than10%6 of the comprehensive energy consumption compared with the fixed cyclemode.

3. The optional dew point energy-saving control can extend the adsorption timeand reduce the comprehensive energy consumption by more than 30% underload fluctuation conditions;