Nitrogen Generator for Medicine Production

In modern pharmaceutical manufacturing, controlling the production environment is critical to ensuring product safety, stability, and compliance with strict regulatory standards.

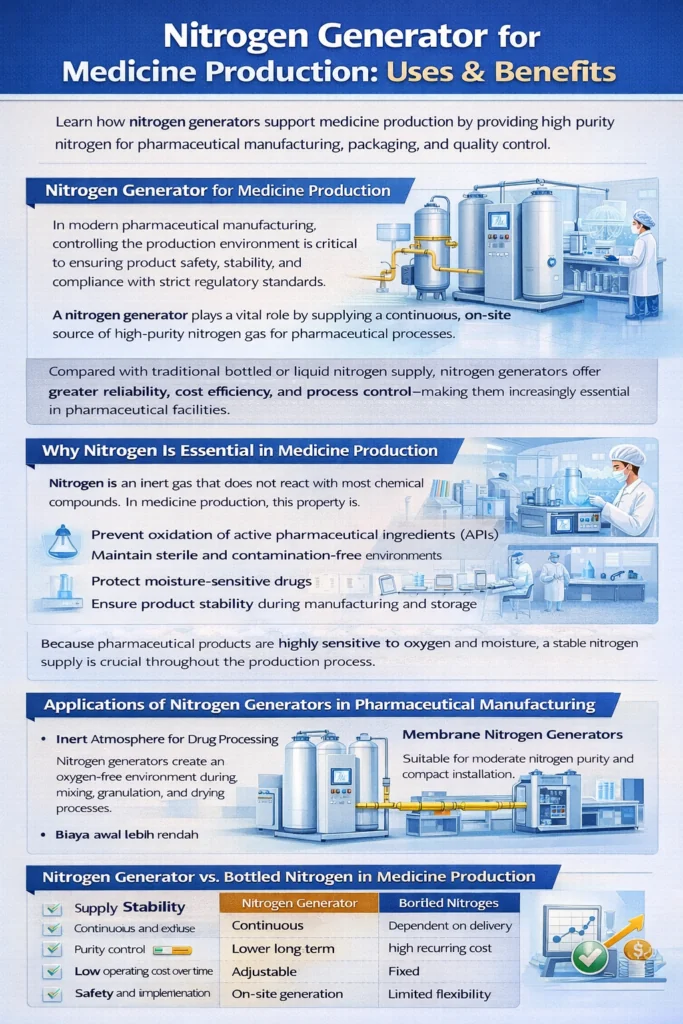

A nitrogen generator plays a vital role in medicine production by supplying a continuous, on-site source of high-purity nitrogen gas for various pharmaceutical processes.

Compared with traditional bottled or liquid nitrogen supply, nitrogen generators offer greater reliability, cost efficiency, and process control—making them increasingly essential in pharmaceutical facilities.

Why Nitrogen Is Essential in Medicine Production

Nitrogen is an inert gas that does not react with most chemical compounds. In medicine production, this property is especially valuable.

Nitrogen is commonly used to:

Prevent oxidation of active pharmaceutical ingredients (APIs)

Maintain sterile and contamination-free environments

Protect moisture-sensitive drugs

Ensure product stability during manufacturing and storage

Because pharmaceutical products are highly sensitive to oxygen and moisture, a stable nitrogen supply is crucial throughout the production process.

Key Applications of Nitrogen Generators in Pharmaceutical Manufacturing

Inert Atmosphere for Drug Processing

Nitrogen generators create an oxygen-free environment during mixing, granulation, and drying processes. This helps preserve drug efficacy and extend shelf life.

Pharmaceutical Packaging and Filling

During vial filling, blister packaging, and ampoule sealing, nitrogen is used to displace oxygen. This reduces degradation and ensures consistent product quality.

Cleanroom and Sterile Production Support

Nitrogen supports sterile environments by minimizing microbial growth and reducing contamination risks in cleanrooms and production lines.

Equipment Purging and Safety

Nitrogen is widely used to purge pharmaceutical equipment, pipelines, and reactors before and after production cycles, improving safety and process efficiency.

Types of Nitrogen Generators Used in Medicine Production

PSA Nitrogen Generators

Pressure Swing Adsorption (PSA) nitrogen generators are the most common choice for pharmaceutical applications.

Nitrogen generator with 99.99% purity—reliable, efficient, and built for demanding industrial applications.

Key features include:

Nitrogen purity up to 99.99%

Continuous on-site nitrogen production

Stable and adjustable output

Low operating cost over time

Membrane Nitrogen Generators

Membrane systems are suitable for applications requiring moderate nitrogen purity and compact installation.

Efficient nitrogen generator providing 99.5% nitrogen purity. Designed for reliable performance in industrial, laboratory, and food packaging applications.

They are often used in:

Small-scale medicine production

Laboratory environments

Auxiliary pharmaceutical processes

If you require a nitrogen generator with 99.99% or other purity levels, please contact Lingyu for customized solutions.

Advantages of Using a Nitrogen Generator in Medicine Production

Using an on-site nitrogen generator provides several advantages over traditional nitrogen supply methods:

Continuous and reliable nitrogen availability

Reduced dependence on external gas suppliers

Lower long-term operating costs

Improved process control and consistency

Enhanced compliance with pharmaceutical quality standards

For pharmaceutical manufacturers, these benefits translate into higher efficiency, better quality assurance, and improved operational safety.

Nitrogen Generator vs. Bottled Nitrogen in Pharmaceutical Use

| Aspect | Nitrogen Generator | Bottled Nitrogen |

|---|---|---|

| Supply Stability | Continuous | Dependent on delivery |

| Operating Cost | Lower long-term | High recurring cost |

| Purity Control | Adjustable | Fixed |

| Safety | On-site generation | Cylinder handling risks |

| Scalability | Easy to expand | Limited flexibility |

Choosing the Right Nitrogen Generator for Medicine Production

When selecting a nitrogen generator for pharmaceutical applications, consider the following factors:

Required nitrogen purity level

Flow rate and production capacity

Compliance with pharmaceutical standards

Integration with existing compressed air systems

Energy efficiency and maintenance requirements

A properly selected nitrogen generator ensures consistent performance and long-term reliability in medicine production.

Conclusion

A nitrogen generator for medicine production is a critical component in modern pharmaceutical manufacturing.

By providing high-purity, stable, and cost-effective nitrogen on demand, nitrogen generators help pharmaceutical companies improve product quality, enhance safety, and maintain regulatory compliance.

Whether used for inert processing, sterile packaging, or cleanroom support, nitrogen generators are an indispensable solution for reliable and efficient medicine production systems.