The refrigerant air dryer dew point is a critical factor in ensuring high-quality compressed air for industrial applications. It determines how effectively moisture is removed from compressed air, protecting equipment, processes, and end products from water damage.

This guide explains what refrigerant air dryer dew point means, how it is measured, why it matters, and how to maintain it for peak efficiency.

What is Refrigerant Air Dryer Dew Point?

The refrigerant air dryer dew point refers to the temperature at which moisture in compressed air begins to condense into liquid water. A lower dew point means drier air, while a higher dew point indicates more residual moisture.

For example, if your refrigerant air dryer dew point is 3°C (37°F), it means that as long as the air temperature remains above this level, condensation will not occur inside your system.

How a Refrigerant Air Dryer Works to Control Dew Point

A refrigerant air dryer lowers the temperature of compressed air to near freezing. This cooling causes water vapor to condense, which is then removed before the air is reheated and sent downstream.

The process:

Warm Air Inlet – Compressed air enters carrying water vapor.

Cooling Stage – A refrigeration circuit reduces air temperature to achieve the desired refrigerant air dryer dew point.

Moisture Separation – A separator removes liquid water.

Reheating – Dried air is reheated to prevent condensation in pipes.

By maintaining a consistent refrigerant air dryer dew point, the system ensures high-quality, moisture-free air.

Typical Refrigerant Air Dryer Dew Point Ranges

Standard Refrigerant Air Dryers – 3°C to 5°C (37°F to 41°F)

High-Temperature Models – Around 5°C to 10°C (41°F to 50°F)

Sub-Zero Dew Point (Desiccant Dryers) – Below -20°C (-4°F)

Most industrial applications use a refrigerant air dryer dew point of around 3°C, which is sufficient to prevent corrosion and equipment damage.

Why Refrigerant Air Dryer Dew Point Matters

Maintaining the correct refrigerant air dryer dew point is essential for:

Preventing Corrosion – Moisture can damage pipes, valves, and pneumatic tools.

Protecting Product Quality – In food, beverage, or pharmaceutical industries, moisture can cause contamination.

Improving System Efficiency – Drier air reduces maintenance needs and downtime.

Extending Equipment Life – Prevents rust, scale buildup, and component failure.

Factors Affecting Refrigerant Air Dryer Dew Point

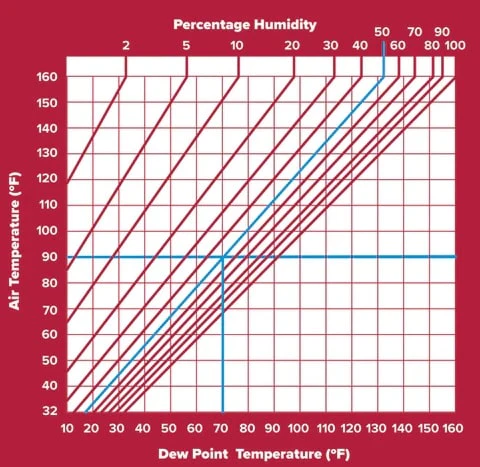

Inlet Air Temperature – Higher temperatures require more cooling to achieve the same dew point.

Humidity Levels – Moist climates challenge dew point control.

Airflow Rate – Overloading the dryer can raise the refrigerant air dryer dew point.

Refrigeration System Performance – Poor refrigerant charge or dirty condensers reduce efficiency.

How to Measure Refrigerant Air Dryer Dew Point

Measuring refrigerant air dryer dew point is done using:

Dew Point Meters – Real-time monitoring devices.

Portable Hygrometers – For spot checks.

Inline Dew Point Sensors – For continuous system monitoring.

Regular dew point checks help identify issues before they cause costly downtime.

Tips to Maintain Optimal Refrigerant Air Dryer Dew Point

Clean Heat Exchangers – Dirt reduces cooling efficiency.

Check Refrigerant Levels – Low refrigerant raises dew point.

Inspect Automatic Drains – Clogged drains can cause moisture carryover.

Avoid Overloading – Keep airflow within rated capacity.

Schedule Preventive Maintenance – Regular service ensures a stable refrigerant air dryer dew point.

FAQ – Refrigerant Air Dryer Dew Point

What is the ideal refrigerant air dryer dew point for general industry?

Around 3°C (37°F) is standard for most industrial applications.

Can refrigerant air dryers reach -40°C dew point?

No, for ultra-low dew points you need a desiccant air dryer.

Why is my refrigerant air dryer dew point higher than normal?

Possible causes include dirty condensers, low refrigerant, or excessive inlet temperature.

How often should I check the dew point?

Monthly for stable systems, weekly in critical applications.

Does a lower refrigerant air dryer dew point mean better air quality?

Yes, but only to a point—ultra-low dew points are unnecessary for most applications.

Conclusion

The refrigerant air dryer dew point is a vital measure of compressed air quality. Keeping it within the right range prevents corrosion, protects equipment, and maintains product quality.

By understanding the factors that affect dew point and following proper maintenance practices, you can ensure your refrigerant air dryer operates efficiently for years.

Whether you run a manufacturing plant, food processing facility, or automotive workshop, managing the refrigerant air dryer dew point is key to keeping your compressed air system running smoothly and cost-effectively.