Compressed air is one of the most versatile power sources in modern industry—but raw compressed air is never clean or dry enough to use directly. It often contains moisture, oil, and solid particles that can damage tools, corrode pipelines, and reduce production quality.

That’s why choosing the right type of compressed air dryer is essential for every operation that relies on compressed air. In this guide, we’ll explain the main types of air dryers, how each works, their pros and cons, and how to choose the one that best fits your application.

💧 Why Every System Needs a Compressed Air Dryer

When air is compressed, its temperature increases, and as it cools, water vapor condenses inside tanks and pipelines. If that moisture is not removed, it can:

Corrode pipes and valves

Damage pneumatic tools and sensitive instruments

Contaminate products in food, pharma, and electronics

Cause costly downtime and repairs

A compressed air dryer eliminates this moisture, ensuring clean, dry, and reliable air—essential for productivity and long-term system health.

⚙️ Main Types of Compressed Air Dryers

There are four major types of compressed air dryers, each with unique advantages and applications.

❄️ 1. Refrigerated Air Dryer – Reliable and Cost-Effective

How it works:

Refrigerated air dryers cool compressed air so water vapor condenses into liquid, which is then drained away.

Advantages:

Affordable and reliable for most uses

Easy to install and maintain

Consistent dew point around 35–40°F (2–4°C)

Limitations:

Not suitable for ultra-dry air requirements

Best for:

General manufacturing, automotive shops, and pneumatic tool systems.

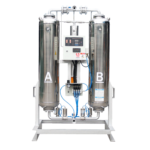

🌵 2. Desiccant Air Dryer – For Ultra-Dry, High-Purity Air

How it works:

Desiccant air dryers use materials like activated alumina or silica gel to absorb moisture from compressed air.

Advantages:

Extremely low dew points (-40°F / -40°C or lower)

Ideal for moisture-sensitive processes

Reliable in cold or humid environments

Limitations:

Higher upfront and maintenance cost

Requires desiccant replacement and occasional purge air

Best for:

Pharmaceuticals, electronics, food processing, and paint applications.

🌀 3. Membrane Air Dryer – Compact and Energy-Efficient

How it works:

Compressed air passes through a semi-permeable membrane that allows water vapor to diffuse out.

Advantages:

No electricity required

Silent operation, low maintenance

Lightweight and space-saving

Limitations:

Limited airflow capacity

Higher cost for large-scale setups

Best for:

Laboratories, medical facilities, and point-of-use applications.

⚗️ 4. Deliquescent Air Dryer – Simple and Portable Moisture Control

How it works:

Uses chemical tablets that absorb moisture and gradually dissolve into liquid.

Advantages:

No electricity required

Simple and cost-effective design

Ideal for remote or outdoor locations

Limitations:

Limited dew point reduction

Requires periodic chemical replacement

Best for:

Pipelines, mining operations, and remote work sites.

📊 Comparison Table – Types of Compressed Air Dryers

| Type | Dew Point | Cost | Best Applications |

|---|---|---|---|

| Refrigerated | 35–40°F (2–4°C) | 💲 Low | General industry, automotive |

| Desiccant | -40°F or lower | 💲💲 High | Pharma, electronics, food, paint |

| Membrane | Moderate | 💲💲 Medium | Labs, medical, point-of-use |

| Deliquescent | 20°F below ambient | 💲 Low | Pipelines, outdoor, remote |

🔍 How to Choose the Right Type of Compressed Air Dryer

When comparing different types, consider:

Dew Point Requirements – Ultra-dry air? Choose desiccant.

Budget – Refrigerated dryers balance cost and reliability.

Energy Efficiency – Membrane or deliquescent dryers save power.

Maintenance – Check desiccant and chemical replacement needs.

Operating Conditions – High humidity or sensitive environments may need advanced models.

💡 Tip: Always match the dryer’s capacity to your compressor’s CFM and operating pressure for optimal performance.

❓ FAQ – Types of Compressed Air Dryers

1. What is the most common compressed air dryer?

Refrigerated air dryers are the most popular due to their affordability and low maintenance.

2. Which air dryer provides the driest air?

Desiccant air dryers, capable of achieving dew points as low as -40°F.

3. Are membrane air dryers suitable for large systems?

Not typically—they’re ideal for small-scale or point-of-use applications.

4. What’s the cheapest type of air dryer?

Deliquescent dryers, though they require ongoing chemical replacement.

5. How often should I maintain my air dryer?

Every 6–12 months, depending on usage and environment.

🏁 Conclusion – Find the Perfect Compressed Air Dryer for Your Needs

Each type of compressed air dryer serves a specific purpose:

Refrigerated dryers – cost-effective and reliable

Desiccant dryers – ultra-dry for precision applications

Membrane dryers – compact and energy-efficient

Deliquescent dryers – simple and field-ready

Choosing the right one depends on your air quality needs, environment, and budget. By investing in the right dryer, you ensure your compressed air system runs clean, dry, and efficient—saving money and protecting equipment for years to come.

Related products:

This 75 CFM (air-cooled) refrigerated air dryer is a reliable and energy-efficient solution, specifically designed to remove moisture from compressed air systems. It is ideal for small to medium industrial applications, providing clean, dry compressed air with a stable pressure dew point. With its compact design and air-cooled operation, this 75 CFM (air-cooled) refrigerated air dryer ensures long-term, stable performance while minimizing maintenance requirements.