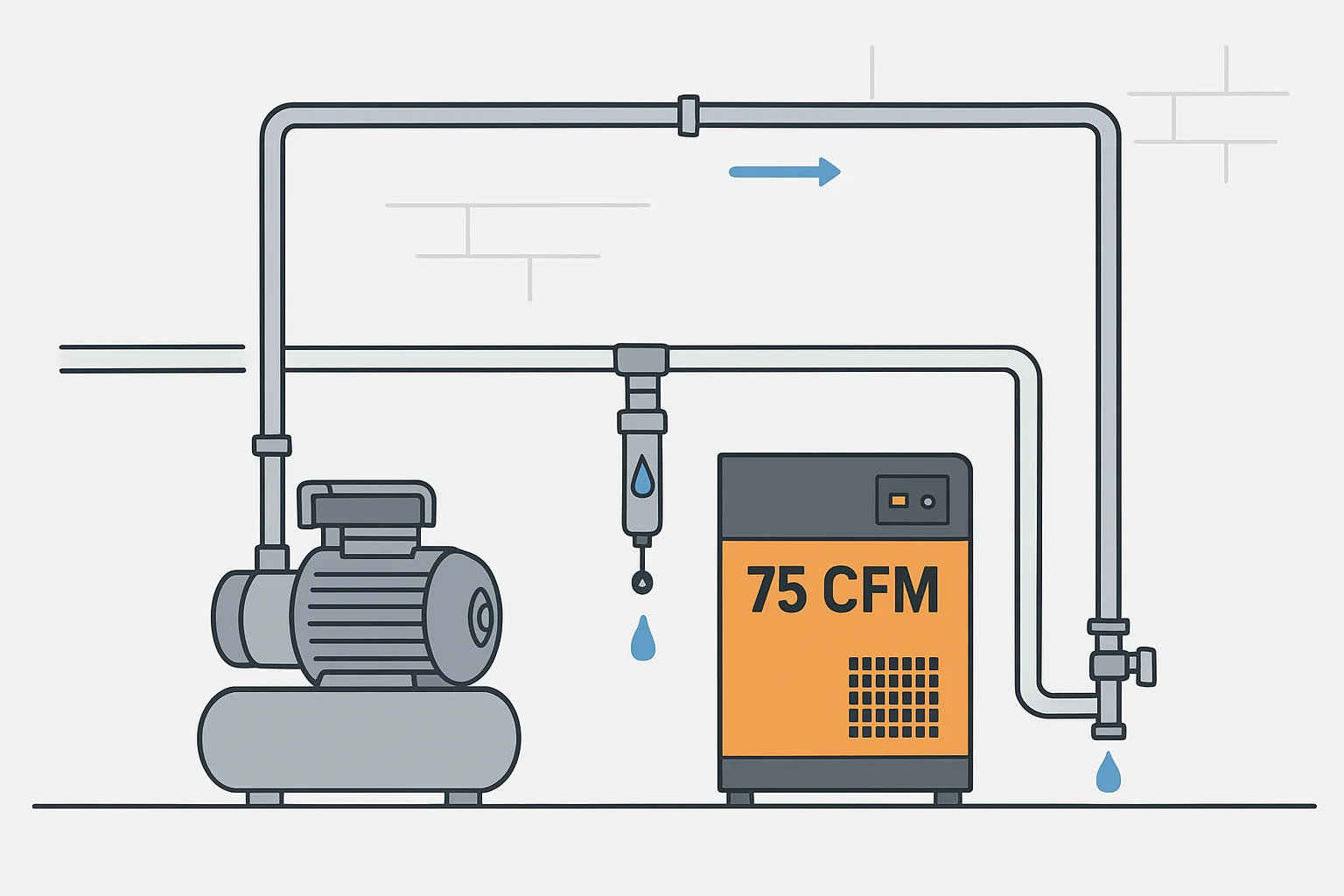

Purchasing and operating a 75 CFM refrigerated air dryer goes beyond just considering technical specifications and basic functions. More importantly, it involves ensuring long-term efficient operation, reducing maintenance costs, and maximizing economic value. This guide provides practical and often overlooked insights for users.

1. Proper Installation and Its Impact on Performance

| Installation Consideration | Recommended Practice | Impact |

|---|---|---|

| Ventilation | Ensure good airflow around the unit and avoid heat accumulation | Improves refrigeration efficiency and reduces compressor load |

| Level Placement | Keep the unit level | Prevents uneven refrigerant levels and abnormal condensate drainage |

| Piping Connections | Avoid sharp bends or excessively long inlet/outlet pipes | Reduces pressure loss and ensures stable airflow |

2. Maintenance and Care Tips

| Maintenance Item | Recommended Frequency | Notes |

|---|---|---|

| Filter inspection & cleaning | Quarterly | Prevents dust and particles from clogging the dryer |

| Automatic drain valve testing | Quarterly | Ensures proper drainage and prevents moisture accumulation |

| Condenser cleaning | Semi-annually | Maintains effective heat dissipation and prolongs compressor life |

| Long-term shutdown care | Before shutdown | Drain air and condensate from piping to prevent corrosion |

3. Energy Saving and Cost Optimization Tips

Adjust usage based on production load; avoid prolonged full-load operation.

Operate under ambient temperatures lower than extreme highs to reduce electricity costs and extend refrigerant life.

Integrate with smart control systems to enable on-demand operation, further reducing energy consumption.

4. Common Troubleshooting Table

| Symptom | Possible Cause | Solution |

|---|---|---|

| Dew point not meeting standard | Clogged filter, excessive airflow, high ambient temperature | Inspect and clean the filter, adjust airflow, or improve ventilation |

| Unusual noise | Loose compressor or fan, dust buildup on the heat exchanger | Tighten bolts and clean dust |

| Poor drainage | Faulty drain valve or bent piping | Clean valve or adjust piping |

5. Long-Term Investment and Returns

| Investment Focus | Long-Term Benefits |

|---|---|

| Equipment protection | Reduces corrosion of piping, pneumatic components, and coating equipment |

| Downtime risk reduction | Prevents production line shutdowns due to moisture problems |

| Product quality improvement | Especially beneficial for coating, food processing, and laboratories, ensuring consistency and reliability |

6. Upgrade and Expansion Options

Integrated air filtration system: Produces ultra-clean air for specialized processes.

Smart monitoring system: Real-time monitoring of dew point and pressure, minimizing manual intervention.

Modular expansion: Increase capacity by paralleling units or upgrading models as air demand grows.

For more product information:

This 75 CFM (air-cooled) refrigerated air dryer is a reliable and energy-efficient solution, specifically designed to remove moisture from compressed air systems. It is ideal for small to medium industrial applications, providing clean, dry compressed air with a stable pressure dew point. With its compact design and air-cooled operation, this 75 CFM (air-cooled) refrigerated air dryer ensures long-term, stable performance while minimizing maintenance requirements.