Fish eye, catering, hazing, low gloss, and dye back are some of the most common quality issues in the paint shop. Some are visible immediately, while others may appear later when the bake cycle is already started. The hidden culprit behind these issues is the moisture and oil in the compressed air.

Let’s unveil some of the common issues raised by compressed air quality and how to address these issues.

Diagnosing the Common Problems Caused by Compressed Air

The principle of air spraying is to atomize the paint using compressed air for application. It can produce a uniform paint film with a delicate and smooth coating; even on relatively concealed parts of components, it can achieve even spraying.

As a highly efficient means of production, the application scope of air spraying is extensive, covering fields such as: hardware, plastic, furniture, automobiles, ships, military industry, and many others.

Compressed air is extensively used in automotive production lines, especially for:

- Vehicle coating using powerful spray guns and robots

- To transport paint to the nozzle

- Before painting, it helps with cleaning and drying processes

There are many small particles and substrates in our atmosphere that are unseen to human eyes. All these unseen contaminants undergo compression and become further concentrated, thereby compromising the quality of the compressed air.

Impurities such as dust, oil, and water vapor can degrade coating quality, ultimately affecting the expected professional finishes.

The following are the most common issues caused by a poor compressed air system in car painting:

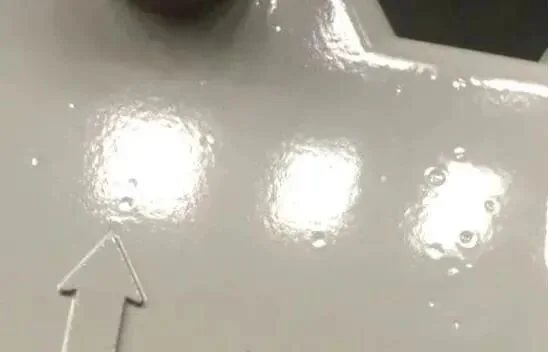

1.Blisters/Bubbles

These are the small areas raised on the surface after the paint has dried. They are formed when the moisture in the air supply expands due to heat. It leads to the formation of air bubbles under the layer of paint.

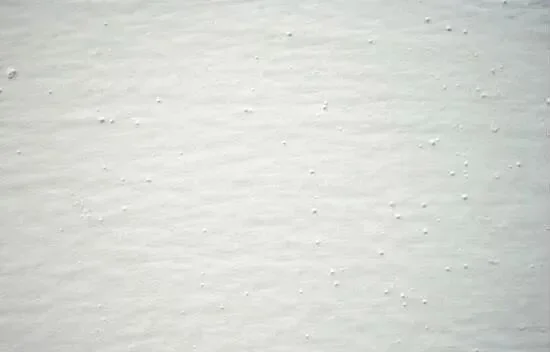

2.Pinholes

These are small craters or holes in paint, often caused by bursting or oil droplets or water vapour during curing.

3.Seedy Finish

It is the irregularly shaped, rough, and sand-like surface that appears on the paint film just after painting. The main culprits are the dust, rust, or oil carried by the air compressor for industrial use.

4.Fisheyes

These are circular craters that prevent paint from adhering, caused by oil contamination from pipelines or compressors.

5.Orange Peel

It appears as an uneven, textured surface that resembles citrus skin. Excessive moisture and unstable airflow disrupt the paint atomization.

6.Blushing/Hazy finish

It’s a cloudy or whitish appearance on the coating. It is caused by condensed water vapour trapped in the film.

7.Sags

These are paint runs or dips resulting from airflow instability and inconsistent drying due to poor compressed air quality.

8.Color Variation

Moisture and oil change the paint’s mixing ratio while applying, resulting in uneven shades or mismatched tones.

Each of these defects results in costly rework, wasted materials, and downtime. High-quality painting is impossible without properly conditioned compressed air for painting.

So, how are these impurities removed from compressed air in industrial applications? Let’s explore this further.

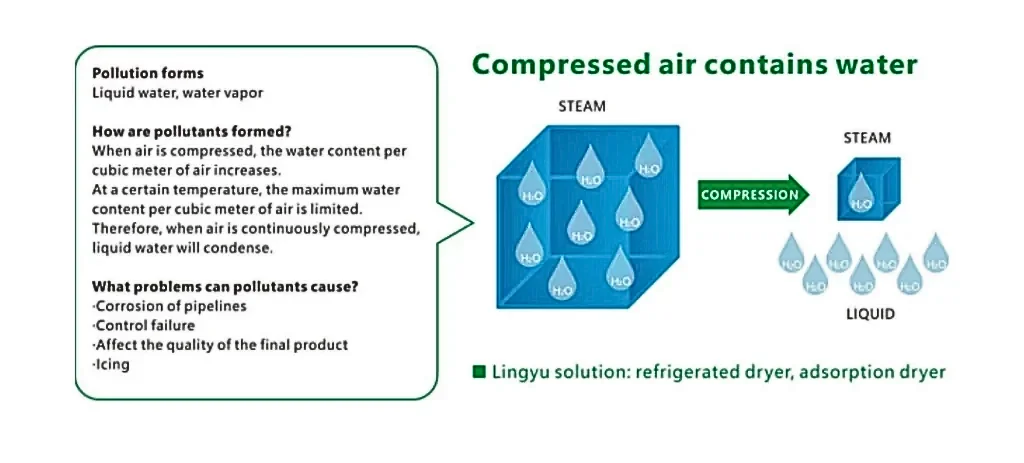

Why Does a Compressed Air System Need a Dryer?

Compressed air works as a power tool for equipment, tools, and processes in paint shops. However, the air that compressors generate contains impurities, which degrade the quality of the compressed air and cause the issues mentioned above.

A compressed air dryer is an ultimate rescuer in such cases, as it removes impurities from the compressed air and provides clean, pure compressed air. Its main function is to work in conjunction with the compressed air system to deliver stable compressed air quality for industrial use.

How does a dryer remove impurities?

A dryer removes impurities from compressed air by using a general cooling principle. This results in condensation of the moisture. In some dryers, a desiccant material is used to absorb the air moisture. The process leads to a consistent supply of dry and clean air to the air compressor for a paint gun or spray robot.

Types of compressed air dryers:

Two different types of air dryers commonly used to provide clean and dry compressed air quality are as follows:

- Refrigerated Air Dryers:

– Air-cooled refrigerated air dryer

– Water-cooled refrigerated air dryer

- Desiccant Air Dryers:

– Heatless desiccant air dryer

Further reading:

If your project is looking for a reliable compressed air dryer solution or would like expert advice on which type of dryer best meets your specific dew point requirements, Lingyu’s professional team will be happy to provide support and guidance.

How to Choose the Best Drying Solution for Your Paint Shop?

The optimal humidity target in paint applications ranges between 40% and 60%[1]. However, some applications require even low humidity.

Just like this, here are a few important factors to consider when selecting a compressed air dryer for painting:

- Required dryness level: For most automotive applications, a dew point in the range of 35°F to 38°F[2]is generally adequate(depending on specific process requirements). The most cost-effective way to achieve this is by using a refrigerated air dryer. For processes with extremely strict humidity requirements, such as precision spraying and high-end automotive painting, desiccant air dryers are typically employed to achieve a lower dew point.

- Air volume and pressure:Match the capacity of your dryer to your air compressor for industrial use.

- Environment:Temperature, humidity, and dust in the workshop directly affect the performance of the dryer for the air compressor. Make sure you have had a proper consultation with your manufacturer or supplier, as they are the experts in the field and can help you choose the right dryer for your environment.

- Operating costs: Evaluate energy consumption and maintenance schedules.

- System integration: Ensure compatibility with filters and other components.

Further reading:

Protect Your Compressed Air Quality with Lingyu

Lingyu, as a professional compressed air dryer partner, has accumulated extensive experience through global collaborations. Our products serve numerous renowned air compressor brands, including Atlas, Hitachi, Ingersoll Rand, Sullair, and Hanbell. For years, we have continuously focused on technology and brand development.

Book a consultation with our team of experts now. Our team of experts will help you choose the right air dryer tailored to your environment and other specific needs.

References:

[1]Optimum temperature and humidity in paint shops: brilliant results! Available at: https://www.blowtherm.it/en/optimum-temperature-and-humidity-in-paint-shops-brilliant-results/ (Accessed: 30 October 2025)

[2]Air Compressor Efficiency in Auto Refinishing. Available at: https://fujisprayauto.com/air-compressor-efficiency-in-auto-refinishing/ (Accessed: 30 October 2025)