How Does a Heatless Desiccant Air Dryer Work?

Heatless Desiccant Air Dryers remove moisture from compressed air by using a desiccant that adsorbs water vapor. Unlike heated models, Heatless Desiccant Air Dryers regenerate the desiccant without using external heat. Here's how Heatless Desiccant Air Dryers typically operate:

Drying Phase: Moist compressed air enters one tower of the Heatless Desiccant Air Dryer, where the desiccant adsorbs moisture and delivers dry air downstream.

Regeneration Phase: While one tower dries the air, a small portion of the dried compressed air (purge air) is diverted through the saturated desiccant bed in the other tower to remove moisture. This process requires no external heat.

Cooling & Switching: After regeneration, the desiccant cools down naturally, and the system automatically switches towers, enabling continuous drying. Heatless Desiccant Air Dryers provide a steady supply of dry compressed air with moderate dew points, typically around -20°C to -40°C.

What Are the Benefits of Using Heatless Desiccant Air Dryers?

Heatless Desiccant Air Dryers are widely used in industries that require dry compressed air without complex heating systems:

- No External Heat Required: Operates without electricity or steam for regeneration, making the system simpler and safer.

- Reliable Drying Performance: Continuous operation with twin towers ensures stable air quality for industrial applications.

- Lower Maintenance Complexity: Fewer components compared to heated dryers reduce potential points of failure.

- Energy Efficient for Small to Medium Systems: Although they use purge air for regeneration, Heatless Desiccant Air Dryers are ideal for systems where electricity or steam is limited or expensive.

- Durable Desiccant Life: Properly sized purge air and optimized cycles maintain desiccant performance over time.

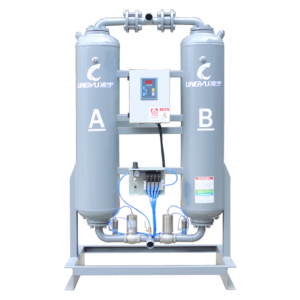

What Are the Features of Lingyu’s Heatless Desiccant Air Dryers?

Lingyu’s Heatless Desiccant Air Dryers are designed for simplicity, reliability, and cost-effective operation. Key features include:

- Advanced Twin-Tower Design: Ensures continuous drying with automatic switching between towers.

- High-Quality Desiccant Beds: Premium desiccants provide efficient moisture adsorption and long service life.

- Digital Control Panel: Monitors system performance in real-time and manages automatic tower switching.

- Corrosion-Resistant Structure: Durable construction suitable for demanding industrial environments.

- Compact and Energy-Efficient: Optimized design reduces overall compressed air consumption during purge cycles.

- Customizable Models: Available in various sizes and capacities to meet industry needs, including electronics, petrochemicals, food processing, and pharmaceuticals.

Regarding Heatless Desiccant Air Dryers

The Ultimate Guide to Heatless Desiccant Air Dryers

Compressed air systems are vital to a wide range of industries—from pharmaceuticals and food process […]

Read More