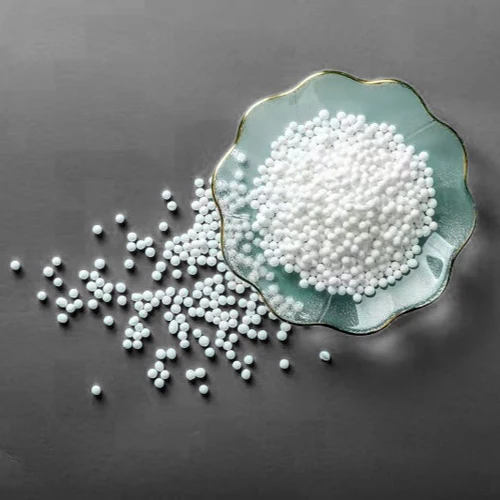

In industrial environments, the quality of compressed air directly affects productivity, equipment life, and product quality. One of the most critical components in maintaining dry and clean compressed air is the air dryer desiccant beads. These small yet powerful beads are designed to absorb moisture and contaminants from compressed air streams, ensuring optimal air quality and system reliability.

In this comprehensive guide, we explore the function, types, replacement tips, advantages, and common questions related to air dryer desiccant beads, helping you make informed decisions to keep your system running smoothly.

What Are Air Dryer Desiccant Beads?

Air dryer desiccant beads are small moisture-absorbing particles used to remove moisture from compressed air. These beads are typically made from silica gel, activated alumina, or molecular sieve. They are widely used in adsorption dryers and are one of the most critical components in compressed air drying systems.

Through physical adsorption, desiccant beads efficiently absorb moisture in high-humidity environments while maintaining their structure and long-term performance.

How Do Air Dryer Desiccant Beads Work to Remove Moisture?

When humid compressed air flows through the dryer containing air dryer desiccant beads, these beads adsorb the moisture in the air, ensuring the air leaving the system is dry. Once the beads are saturated, the system enters a regeneration phase, using heat or dry air to release the moisture from the beads, making them ready for reuse.

The Adsorption Drying Process Consists of Two Stages:

Adsorption Stage: Moisture molecules attach to the surface of the desiccant beads.

Regeneration Stage: Heat or dry air is used to release the moisture from the beads.

This cyclical process ensures the system continues producing dry air.

Common Types of Air Dryer Desiccant Beads

Choosing the right type of air dryer desiccant beads is essential, as different types vary in moisture absorption capacity, operating temperature, and lifespan.

1. Silica Gel

High moisture absorption capacity, suitable for normal temperature environments

Color-changing indicators, making it easy to see when the beads are saturated

Commonly used in electronics, food packaging, and general industrial applications

2. Activated Alumina

Can withstand higher temperatures

Excellent regeneration performance

Long-lasting and used in industrial automation, spray systems, and more

3. Molecular Sieve

Fast absorption rate, can achieve dew points below -70°C

Designed for ultra-dry environments, such as pharmaceuticals and semiconductors

When to Replace Air Dryer Desiccant Beads?

Even the best-quality desiccant beads will lose performance over time. Here are key signs that indicate when it’s time to replace the beads:

Rising Dew Point: The air exiting the system is no longer consistently dry, indicating the desiccant beads are saturated.

Increased Energy Consumption: If the regeneration process is happening more frequently, it may mean the beads’ moisture-absorbing capacity is diminishing, leading to higher energy usage.

Color Change: Some types of silica gel beads change color when saturated, providing a visual cue that it’s time for replacement.

Shortened Operating Cycles: If regeneration cycles become more frequent, it’s a sign the beads are no longer functioning as efficiently.

Recommended Replacement Cycle: Typically, desiccant beads should be checked or replaced every 12-24 months, depending on operating conditions and usage.

How to Properly Replace Air Dryer Desiccant Beads?

To ensure your air drying system runs efficiently, follow these steps when replacing air dryer desiccant beads:

Power Down and Depressurize: Always turn off the power and release any compressed air before beginning the replacement process.

Remove the Dryer Cover: Open the access points based on your dryer’s model.

Remove the Old Desiccant Beads: Carefully remove the old beads and inspect the internal components.

Clean the Dryer Internally: Use a dry cloth or compressed air to clean the internal surfaces of the dryer.

Add Fresh Beads: Follow the manufacturer’s instructions for the correct amount and type of beads.

Seal and Restart: After sealing the dryer, restart the system and monitor for any issues.

Benefits of Using Air Dryer Desiccant Beads

Using high-quality air dryer desiccant beads offers numerous benefits for compressed air systems:

✅ High Drying Efficiency: Effectively lowers the dew point, ensuring no residual moisture in the air.

✅ Equipment Protection: Prevents corrosion, blockages, and malfunctions in pneumatic equipment and pipes.

✅ Energy Savings: Reduces energy waste caused by excessive regeneration cycles.

✅ Extended Equipment Life: Keeps the system clean, reducing the frequency of repairs and maintenance.

✅ Compliance with Industry Standards: Meets the stringent air quality requirements of industries like food, pharmaceuticals, and electronics.

Common Applications of Air Dryer Desiccant Beads

Air dryer desiccant beads are widely used in various industries to ensure clean, dry compressed air. Common applications include:

Spray Painting: Prevents moisture from affecting the paint finish and product quality.

Food and Pharmaceutical Manufacturing: Helps prevent contamination and bacteria growth in processing environments.

Automation and Pneumatic Equipment: Maintains the precision and responsiveness of equipment.

Semiconductor Manufacturing: Ensures ultra-dry air for critical processes.

Laboratory Air Systems: Provides stable and clean air for sensitive laboratory equipment.

FAQ: Common Questions About Air Dryer Desiccant Beads

1. How do I know when my desiccant beads need replacing?

Monitor the dryer’s performance, dew point, and energy consumption. If there’s a noticeable degradation in performance or a color change in silica gel beads, it’s time to replace them.

2. Can I mix different types of desiccant beads?

It is not recommended. Mixing different types can lead to uneven moisture absorption and potentially compromise the dryer’s performance.

3. Can desiccant beads be regenerated?

Some desiccant beads can be regenerated using heat or vacuum methods, but it is generally recommended to replace them for optimal performance.

4. Are all dryers using desiccant beads?

No. Only adsorption dryers (Desiccant Air Dryers) use desiccant beads. Refrigerated dryers, on the other hand, use cooling techniques to remove moisture.

5. What is the best way to store desiccant beads?

Store desiccant beads in dry, sealed containers to prevent them from absorbing moisture before use. They can typically be stored for 6-12 months in their sealed packaging.

Conclusion

In compressed air systems, air dryer desiccant beads are a crucial component for maintaining dry and clean air. By understanding their function, types, replacement cycles, and maintenance tips, you can ensure that your air dryer system operates at peak efficiency, preventing moisture-related issues and protecting your equipment.

Whether you are involved in electronics manufacturing, food processing, or high-end industrial applications, investing in high-quality air dryer desiccant beads and maintaining them properly will keep your operations smooth and cost-effective.

Related products:

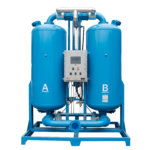

2, Minimum regeneration gas consumption

3. Long service life of adsorbent

4. Easy maintenance

5. High safety

6. High reliability

7.Adjustable regeneration gas consumption

8. Optional dew point monitoring and control system

2. Resists chemical corrosion and extends service life

3. Special sealing technology prevents flammable gases or dust from entering theinterior of the machine

4. Regeneration gas consumption can be adjusted, with energy saving and dewpoint adjustment function

2, Customized high-performance adsorbent, 20% filling margin;

3. Branded high-pressure blower, high-performance pneumatic valve, high-efficiency cooler designed by HTFS software, reliable performance and long life;

4. 304 stainless steel control gas pipeline, specially designed diverter, highadsorbent utilization rate and low gas pressure loss;