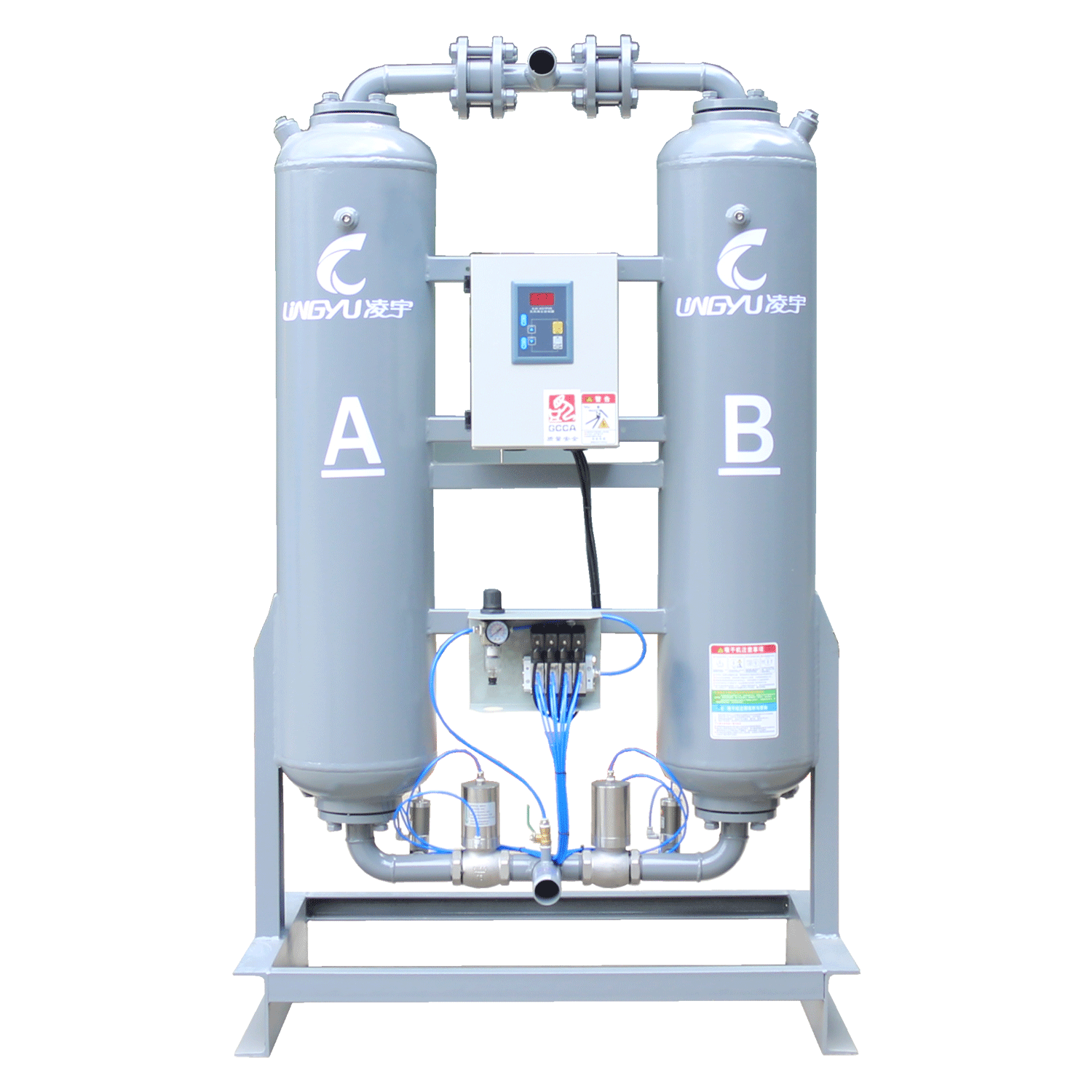

The CH Series Heatless Regeneration Adsorption Dryer provides ultra-dry compressed air using variable pressure adsorption with highly absorbent activated alumina or molecular sieve. While technical specs cover airflow, dew point, regeneration method, and operating conditions, users often seek guidance on practical selection, industrial applications, maintenance, and efficiency optimization.

1. How to Choose the Right CH Series Dryer

Key considerations for selecting a CH Series dryer:

Airflow capacity: Match your system’s peak airflow (3.8–150 m³/min). For fluctuating loads, slightly oversize to maintain consistent dew points between -50℃ and -20℃.

Inlet conditions: Ensure air pressure (0.6–1.0 MPa standard) and inlet temperature (10–30℃ recommended, ≤40℃ max) are compatible.

Regeneration method: The heatless design uses a portion of dry air (8–14%) for regeneration, providing simplicity and low maintenance.

Ambient conditions: Operate in 2–45℃ for optimal efficiency.

Customization: For air volumes above 150 m³/min or special specifications, contact Lingyu for tailored solutions.

Tip: Selecting a dryer slightly above your maximum airflow ensures stable outlet dew points and reduces the risk of moisture breakthrough.

2. Typical Industrial Applications

CH Series dryers are used in industries requiring ultra-dry, oil-free compressed air:

Laboratory & Analytical Equipment: Ozone generators, laboratory analyzers, gas chromatographs, FTIR spectrometers.

Medical & Dental: Dental air compressors, medical air systems, dry nitrogen generation.

Electronics & Semiconductors: Chip testing, circuit board manufacturing, cleanrooms.

Automation & Robotics: Pneumatic automation systems, robotic machinery, air bearings.

Industrial & Manufacturing Controls: Car wash systems, bus door locking systems, air-operated pumps, dry sprinkler systems.

Specialized Processes: Waveguide drying, antenna pressurization, air turbines, graphic printers, vortex tubes.

3. Maintenance and Operational Tips

To maximize reliability and dryer life:

Monitor pressure drop: A rising pressure drop signals clogged adsorbent beds.

Verify regeneration cycles: Ensure proper operation of heatless regeneration using 8–14% of dry air.

Check inlet/outlet connections: Ensure tight, debris-free connections.

Maintain ambient conditions: Avoid high temperatures or poor ventilation that can impact adsorption efficiency.

Schedule adsorbent replacement: Replace molecular sieve or alumina per manufacturer guidelines, especially in humid or contaminated air environments.

4. Energy Efficiency and Optimization

Heatless design simplicity: Minimal moving parts reduce maintenance and operational complexity.

Monitor regeneration air consumption: Optimize airflow used for regeneration (8–14%) to improve overall efficiency.

Use pre-filters: Remove oil and large particles before the dryer to protect adsorbent beds.

Air receiver integration: Stabilizes airflow, reduces cycling, and lowers energy use.

Regular dew point checks: Maintain -50℃ to -20℃ dew points for critical industrial applications.

5. Why Choose Lingyu CH Series Dryers?

Lingyu provides more than reliable dryers:

Custom solutions for airflow, pressure, and dew point requirements.

Comprehensive air treatment systems for industrial, medical, and laboratory applications.

Global support and consultation to optimize dryer selection and system integration.

Fast delivery and after-sales service to ensure uninterrupted operations.

Conclusion

Selecting a CH Series Heatless Regeneration Adsorption Dryer is about more than technical specifications. Considering airflow, regeneration method, operating conditions, and industry application ensures stable ultra-dry air, high efficiency, and long service life. Lingyu’s CH Series delivers reliable, energy-efficient solutions for critical compressed air systems.

For more product information:

2.Minimum regeneration gas consumption

3, Long service life of adsorbent

4. Easy maintenance

5. High safety

6. High reliability

7. Adjustable regeneration gas consumption

8. Optional dew point monitoring and control system