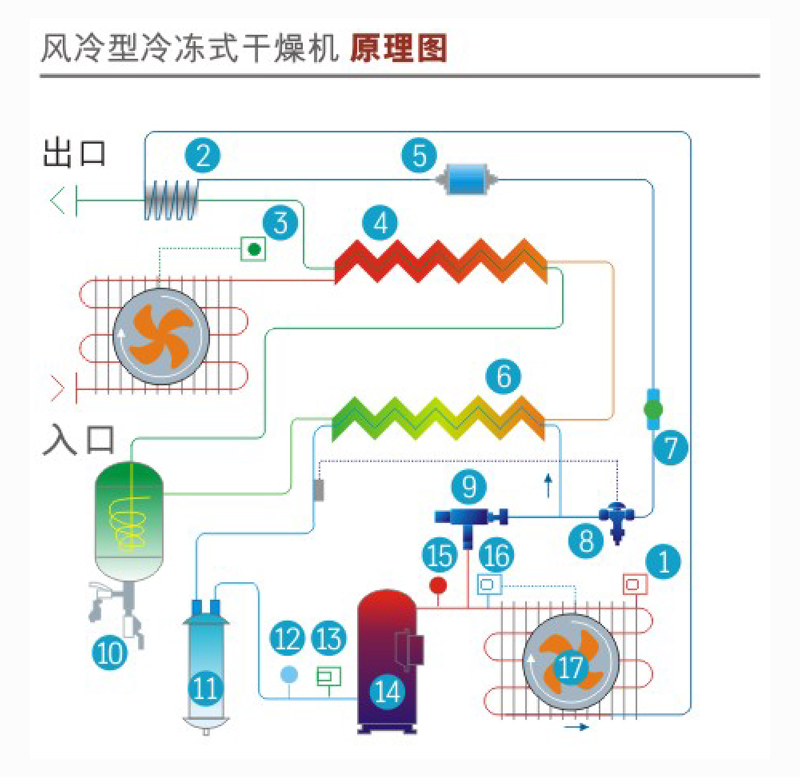

The refrigerated dryer cools the compressed air to condense the water vapor into liquid water, and then separates the water and compressed air through a separator.

Thereby achieving the purpose of drying compressed air. In this process, the refrigeration system is the core part, and its energy consumption occupies the entire freeze dryer function.

consume most of it.

So, how do you reduce the energy consumption of a refrigerated dryer? Here are some suggestions:

- Optimize the refrigeration system: Optimization of the refrigeration system is the key to reducing the energy consumption of the refrigerated dryer. Companies can choose efficient compressors,

Equipment such as heat exchangers and valves improve the efficiency of the refrigeration system. In addition, variable frequency speed regulation technology can also be used to adjust the speed according to the actual compressed air

Adjust the operating speed of the refrigeration system according to actual needs to avoid no-load operation and overload operation, thereby reducing energy consumption.

- Reduce air loss: During the operation of the refrigerated dryer, the compressed air will cause air loss due to pressure changes. Companies can optimize management

Pipe system, reducing the length of pipelines and the number of elbows and other measures can reduce the pressure loss of compressed air, thereby reducing air loss and energy consumption.

- Regular maintenance and upkeep: The energy consumption of the refrigerated dryer is closely related to the working status of the equipment. Enterprises should regularly maintain and maintain equipment

maintenance to ensure the equipment is in good working condition. This can extend the service life of the equipment and reduce energy consumption.

- Improve the utilization rate of compressed air: Enterprises can reduce compression by improving production processes and increasing the recycling rate of compressed air.

air demand, thereby reducing the operating time of the refrigerated dryer and achieving energy saving effects.

Related products:

The 3885 CFM refrigerated air dryer (water cooled) is a high-capacity industrial solution designed for removing moisture from large-scale compressed air systems. Built for continuous and demanding operation, this water-cooled unit ensures a steady dew point and maximum system protection. Whether you're operating in petrochemical, steel, manufacturing, or pharmaceutical industries, the 3885 CFM refrigerated air dryer delivers superior drying performance and energy efficiency.

The 4238 CFM refrigerated air dryer (water cooled) is a high-capacity, industrial-grade dryer designed to eliminate moisture from large compressed air systems. Built with a powerful water-cooled refrigeration circuit, this dryer ensures reliable and continuous moisture removal with a stable pressure dew point. For industries that demand high airflow rates and dependable air quality, the 4238 CFM refrigerated air dryer (water cooled) is the ideal solution.

The 8830 CFM refrigerated air dryer (water cooled) is a top-tier industrial solution engineered to remove moisture from large-scale compressed air systems. Built for ultra-high capacity applications, this dryer ensures consistently dry air with a stable dew point and superior thermal control using an advanced water-cooled condenser system.