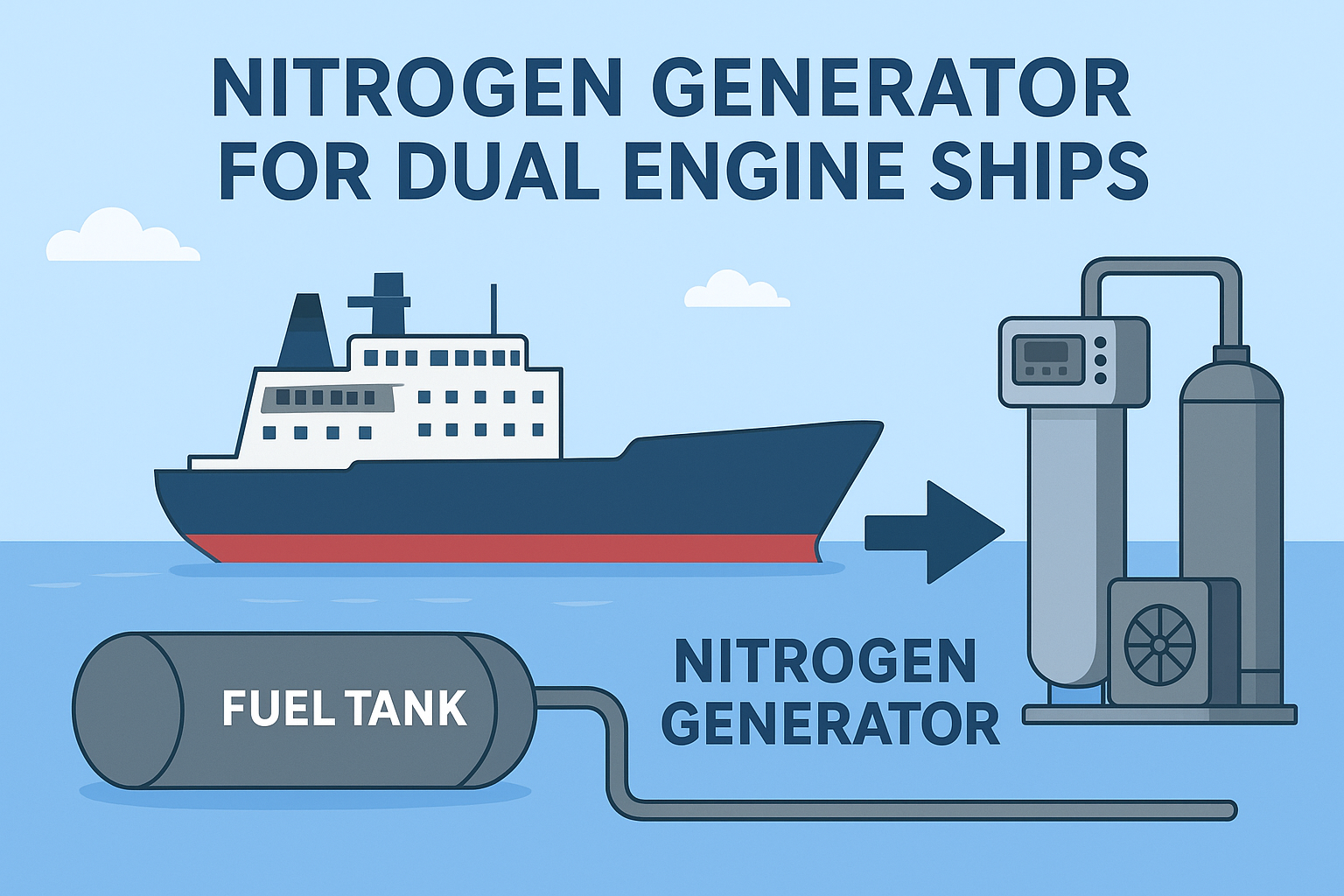

In the marine industry, safety and reliability are top priorities—especially on dual engine ships, where uninterrupted operation is crucial. One technology that has become increasingly important for modern vessels is the nitrogen generator. These systems supply high-purity nitrogen on board, ensuring safe fuel handling, preventing fires, and enhancing long-term operational efficiency.

In this article, we explore what a nitrogen generator is, how it works on dual engine ships, and why it has become an indispensable part of marine engineering.

What Is a Nitrogen Generator for Ships?

A nitrogen generator is an on-board gas production system that separates nitrogen from compressed air. Instead of relying on nitrogen cylinders or external suppliers, the ship can generate a continuous supply of nitrogen directly on the vessel.

This nitrogen—typically between 95% and 99.999% purity—is used for:

Fuel tank inerting

Fire prevention

Pipeline purging

Cargo protection

Gas blanketing

For dual engine ships, which often consume large amounts of fuel and operate for long hours, having a reliable nitrogen supply is critical for safety and stability.

Why Dual Engine Ships Need a Nitrogen Generator

Dual engine ships, including offshore vessels, cargo ships, tankers, and large fishing vessels, face several safety challenges:

1. Prevention of Fuel Tank Explosions

Fuel tanks contain hydrocarbon vapors. When mixed with oxygen, they create an explosive atmosphere.

Nitrogen reduces the oxygen concentration, making the environment inert and safe.

2. Increased Redundancy and Safety

Dual engine ships rely on two engines for power and backup. A nitrogen generator adds another layer of redundancy by ensuring:

No nitrogen supply interruptions

Stable engine room operation

Reduced risk of fire or vapor ignition

3. Improved Efficiency for Long Voyages

During long-distance travel, nitrogen cylinders quickly become impractical. A nitrogen generator provides unlimited nitrogen on demand, lowering operational costs and ensuring continuous safety.

4. Compliance With International Marine Regulations

Modern vessels must comply with safety standards such as:

IMO (International Maritime Organization)

SOLAS regulations

MARPOL guidelines

Nitrogen inerting is often required, especially for tankers and vessels handling volatile fuels.

How a Nitrogen Generator Works on a Dual Engine Ship

Most marine nitrogen generators use either PSA technology or membrane separation, but their basic operation is similar.

1. Compressed Air Supply

The ship’s compressor sends clean, dry air into the nitrogen generator.

Dual engine ships usually have robust compressed air systems, making integration easy.

2. Nitrogen Separation

Depending on the technology:

PSA (Pressure Swing Adsorption): Uses carbon molecular sieves to absorb oxygen and allow nitrogen to pass through.

Membrane Technology: Uses selective membranes that let oxygen escape while nitrogen remains.

3. Nitrogen Storage or Distribution

Generated nitrogen is stored in dedicated tanks or sent directly to:

Fuel tanks

Cargo holds

Fire-suppression lines

Ventilation and blanketing systems

4. Continuous Monitoring and Control

Marine nitrogen generators include sensors to monitor:

Purity levels

Pressure

Flow rate

System health

This ensures constant and reliable nitrogen delivery.

Benefits of Using a Nitrogen Generator on Dual Engine Ships

✔ On-Demand Nitrogen Supply

No need to load, transport, or refill nitrogen cylinders.

✔ Enhanced Marine Safety

Reduces the risk of explosions, fires, and oxidation.

✔ Lower Operating Costs

After installation, nitrogen production costs are significantly lower than cylinder replacement.

✔ Compact and Marine-Grade Design

Built to withstand vibration, humidity, and harsh sea environments.

✔ Long Service Life With Minimal Maintenance

PSA and membrane generators are highly durable and easy to maintain.

✔ Compliant With Global Safety Standards

Meets IMO, SOLAS, and class society requirements.

Common Applications on Dual Engine Ships

Nitrogen generators are used across various systems, including:

Fuel tank inerting

Purging and blanketing

Cargo safety for chemical tankers

Fire protection systems

Engine room safety

Fuel storage and transfer operations

Dual engine vessels, which consume more fuel and often operate in challenging environments, benefit heavily from these protections.

Conclusion

A nitrogen generator for dual engine ships is not just a convenience—it’s a vital component of modern marine safety systems. By preventing fuel tank explosions, reducing fire risks, and ensuring compliance with international regulations, nitrogen generators play a crucial role in protecting the vessel, crew, and cargo.

Come and choose your product

Nitrogen generator with 99.99% purity—reliable, efficient, and built for demanding industrial applications.

Generate 99% pure nitrogen with our advanced nitrogen generator. Designed for stable performance, energy efficiency, and easy maintenance.

Efficient nitrogen generator providing 99.5% nitrogen purity. Designed for reliable performance in industrial, laboratory, and food packaging applications.

2, online real-time monitoring of nitrogen purity and flow rate;

3, long-term alarm and automatic shutdown of unqualified nitrogen;

4. automatic carbon molecular sieve compression device :

5. digital touch screen display of operating status;