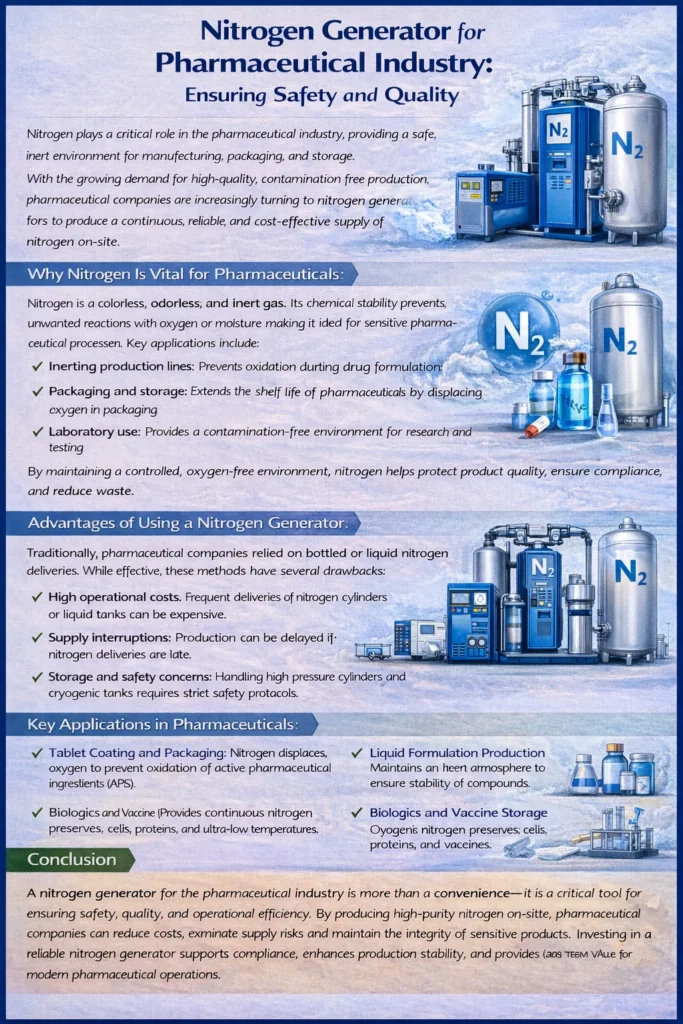

Nitrogen plays a critical role in the pharmaceutical industry, providing a safe, inert environment for manufacturing, packaging, and storage. With the growing demand for high-quality, contamination-free production, pharmaceutical companies are increasingly turning to nitrogen generators to produce a continuous, reliable, and cost-effective supply of nitrogen on-site.

Why Nitrogen Is Vital for Pharmaceuticals

Nitrogen is a colorless, odorless, and inert gas. Its chemical stability prevents unwanted reactions with oxygen or moisture, making it ideal for sensitive pharmaceutical processes. Key applications include:

Inerting production lines: Prevents oxidation during drug formulation or chemical reactions.

Packaging and storage: Extends the shelf life of pharmaceuticals by displacing oxygen in packaging.

Laboratory use: Provides a contamination-free environment for research and testing.

Cryogenic preservation: Liquid nitrogen is used for storing biological samples, vaccines, and other temperature-sensitive materials.

By maintaining a controlled, oxygen-free environment, nitrogen helps protect product quality, ensure compliance, and reduce waste.

Challenges of Traditional Nitrogen Supply

Traditionally, pharmaceutical companies relied on bottled or liquid nitrogen deliveries. While effective, these methods have several drawbacks:

High operational costs: Frequent deliveries of nitrogen cylinders or liquid tanks can be expensive.

Supply interruptions: Production can be delayed if nitrogen deliveries are late.

Storage and safety concerns: Handling high-pressure cylinders and cryogenic tanks requires strict safety protocols.

Limited flexibility: Scaling production or adjusting nitrogen purity often requires complex logistics.

Advantages of Using a Nitrogen Generator

A nitrogen generator for the pharmaceutical industry solves these challenges by producing nitrogen on-site, as needed. Modern systems typically use Pressure Swing Adsorption (PSA) or membrane technology to generate nitrogen with high purity levels suitable for pharmaceutical applications.

Benefits include:

Consistent High Purity: Nitrogen generators can produce gas up to 99.999% purity, ensuring compliance with pharmaceutical standards.

Cost Efficiency: Eliminates recurring expenses on cylinder deliveries or liquid nitrogen procurement.

On-Demand Supply: Provides continuous nitrogen 24/7, ensuring uninterrupted operations.

Safety: Reduces the need for storing high-pressure cylinders or handling cryogenic liquids.

Scalability: Can be tailored for small laboratories or large production facilities.

Regulatory Compliance: Supports ISO and GMP standards for pharmaceutical production and storage.

Key Applications in Pharmaceuticals

Tablet Coating and Packaging: Nitrogen displaces oxygen to prevent oxidation of active pharmaceutical ingredients (APIs).

Liquid Formulation Production: Maintains an inert atmosphere to ensure stability of chemical compounds.

Biologics and Vaccine Storage: Cryogenic nitrogen preserves cells, proteins, and vaccines at ultra-low temperatures.

Analytical Laboratories: Supplies high-purity nitrogen for chromatography, mass spectrometry, and other sensitive analyses.

Selecting the Right Nitrogen Generator

When choosing a nitrogen generator for pharmaceutical use, consider:

Purity Requirements: Match the generator to the nitrogen purity needed for your processes.

Flow Rate and Pressure: Ensure the system meets production demands.

Energy Efficiency: Look for systems that minimize compressed air consumption and operating costs.

Maintenance and Reliability: Choose generators with low maintenance requirements and responsive technical support.

Regulatory Compliance: Ensure the system complies with GMP, ISO, and other pharmaceutical standards.

Conclusion

A nitrogen generator for the pharmaceutical industry is more than a convenience—it is a critical tool for ensuring safety, quality, and operational efficiency. By producing high-purity nitrogen on-site, pharmaceutical companies can reduce costs, eliminate supply risks, and maintain the integrity of sensitive products. Investing in a reliable nitrogen generator supports compliance, enhances production stability, and provides long-term value for modern pharmaceutical operations.