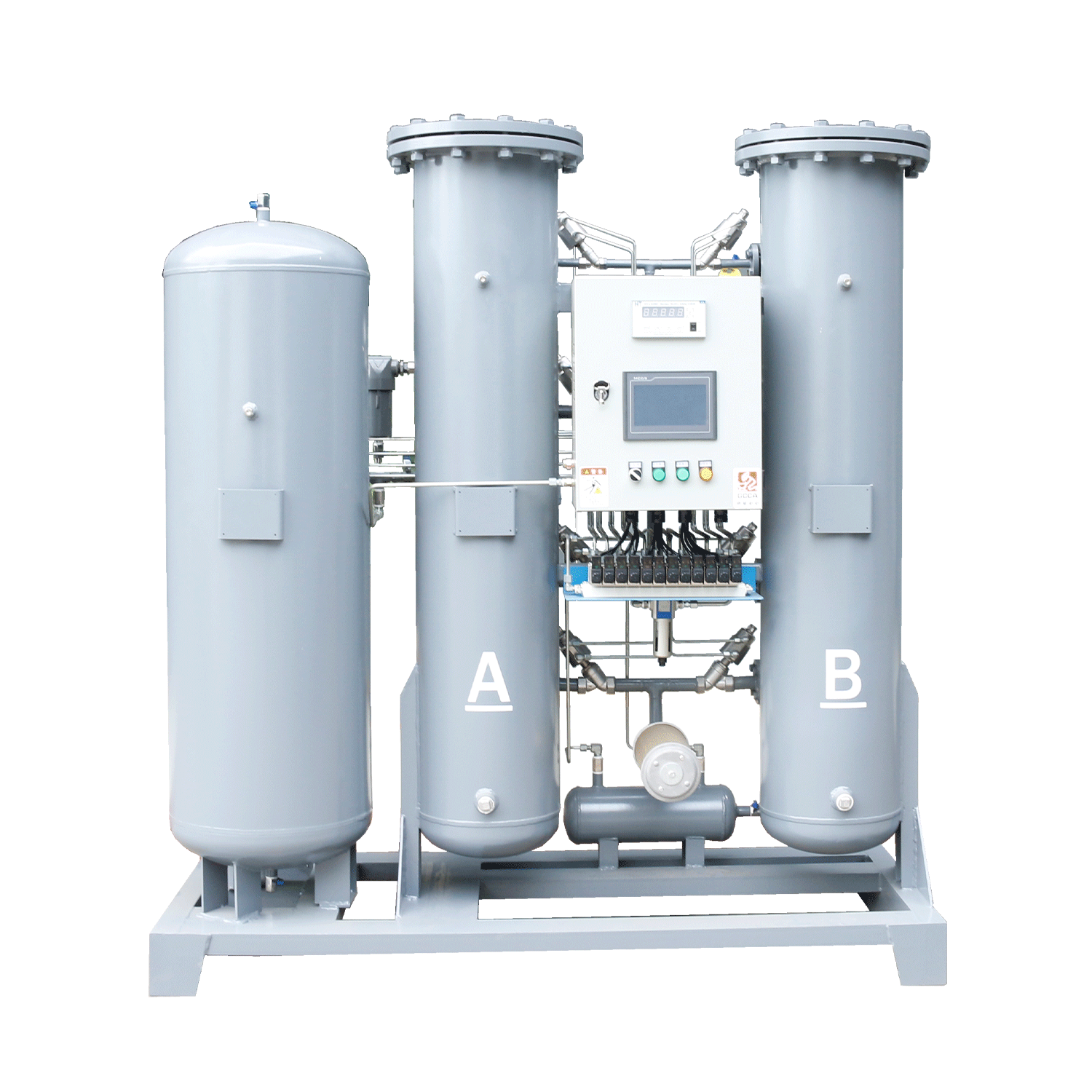

PSA Nitrogen Generator – 99.5% High-Purity Nitrogen

The PSA (Pressure Swing Adsorption) Nitrogen Generator is designed to provide high-purity nitrogen efficiently and reliably. It consists of two adsorption vessels that alternate between adsorption and regeneration. Each vessel is filled with carbon molecular sieves (CMS), which selectively capture oxygen while allowing nitrogen to pass through.

How the PSA Nitrogen Generator Works

When compressed air enters Tower A, oxygen molecules are adsorbed by the carbon molecular sieve, and nitrogen is collected from the outlet. At the same time, Tower B undergoes regeneration, releasing previously adsorbed oxygen into the atmosphere with a small portion of nitrogen. Once Tower A becomes saturated, the system switches automatically via a PLC controller, ensuring continuous nitrogen production.

Operating Conditions & Technical Requirements

Inlet Temperature: ≤ 40℃

Inlet Pressure: 0.5–0.8 MPa

Nitrogen Purity: 95%–99.999%

Nitrogen Dew Point: ≤ -40℃

Ambient Temperature: ≤ 40℃

Switching Cycle: 45–60 seconds

Voltage/Frequency: 220V / 50Hz

Noise Level: ≤ 75 dB

LY ZD-C Series Technical Parameters (Nitrogen Purity: 99.5%)

| Nitrogen Production (m³/h) | Inlet Pipe | Outlet Pipe | Dimensions H×L×W (mm) | Effective Air Consumption (m³/min) |

|---|---|---|---|---|

| 12 | DN15 | DN15 | 1500×850×500 | 0.60 |

| 20 | DN20 | DN15 | 1800×900×600 | 1.00 |

| 50 | DN25 | DN25 | 2400×1150×700 | 2.50 |

| 100 | DN40 | DN40 | 2600×1400×900 | 5.00 |

| 150 | DN50 | DN40 | 2750×1750×900 | 7.50 |

| 250 | DN65 | DN50 | 2890×2200×1200 | 12.50 |

| 400 | DN80 | DN65 | 2900×2500×1350 | 20.00 |

Note: For nitrogen purity up to 99.999%, please contact us for customized solutions.

Applications Users Often Want to Know

High-purity nitrogen produced by PSA generators is widely used in:

Food packaging and storage

Electronics manufacturing and testing

Pharmaceutical and chemical production

Laboratory analysis and instrumentation

Metal processing and laser cutting

Beverage bottling and inerting operations

Oil and gas applications

Additional Considerations

Users often ask about:

Storage & Delivery: Integration with tanks or pipelines for continuous supply.

Purity Monitoring: Sensors for real-time nitrogen purity verification.

Scalability: Options to expand production capacity for future needs.

Maintenance & Support: Spare parts, service contracts, and technical guidance.

Safety Features: Pressure relief valves, alarms, and automated controls.

The LY ZD-C Series PSA Nitrogen Generator provides not only 99.5% pure nitrogen but also reliable, energy-efficient, and customizable solutions tailored to industrial requirements.