In compressed air systems, maintaining air quality is essential for both system performance and longevity. One of the critical components for ensuring clean and dry air is the air dryer. Among the different types of air dryers, water cooled refrigerant air dryers stand out as an effective and energy-efficient solution for moisture removal. In this guide, we will explore how water cooled refrigerant air dryers work, their benefits, and factors to consider when selecting the right one for your system.

What Is a Water Cooled Refrigerant Air Dryer?

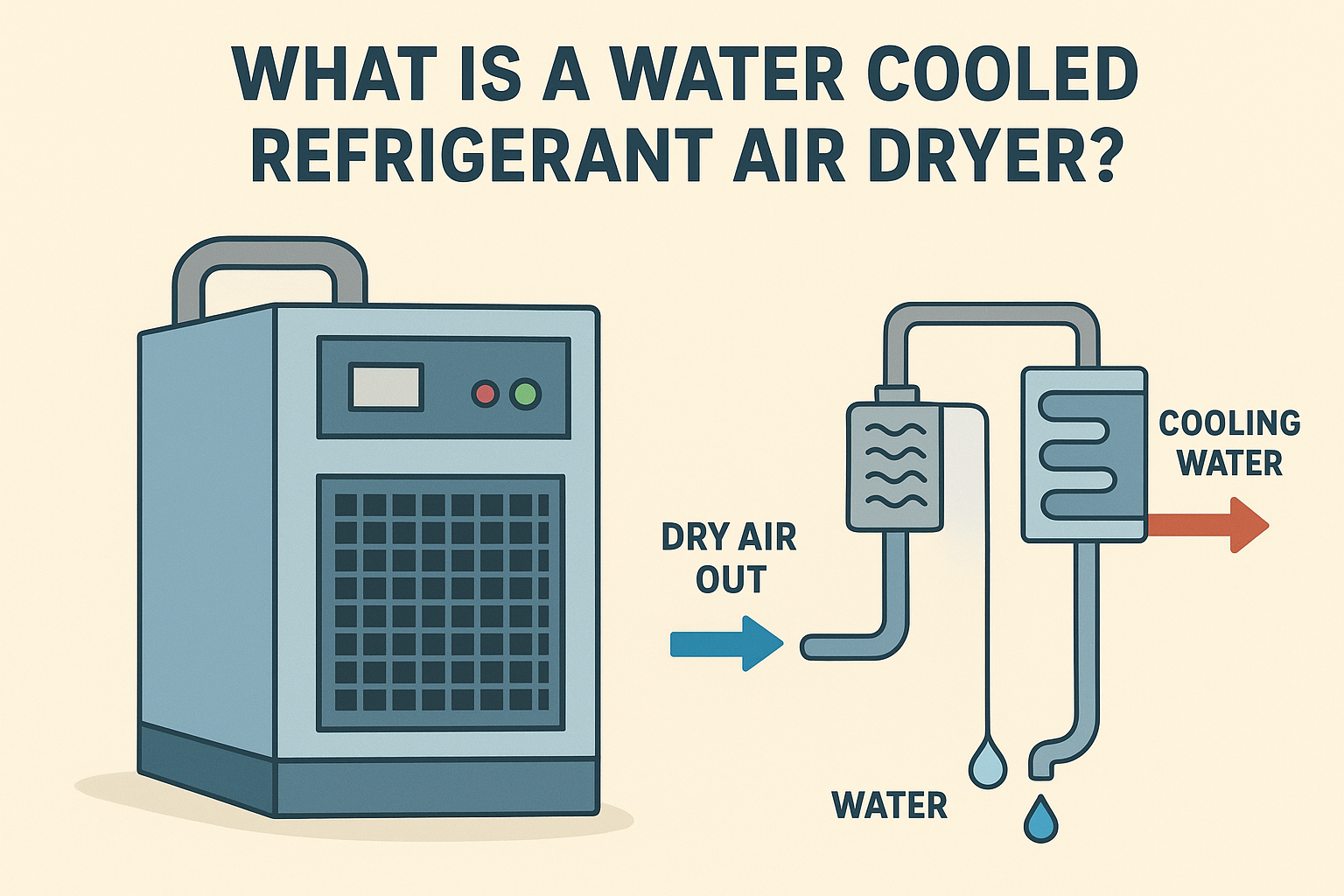

A water cooled refrigerant air dryer is a type of refrigeration-based dryer that uses water as a cooling medium to remove moisture from compressed air. The principle behind these dryers is quite simple: compressed air, which is saturated with moisture, is cooled to a temperature where the moisture condenses into liquid form. The condensed water is then removed from the air before it reaches the equipment.

The drying process involves two key components:

Refrigerant Circuit: The system uses refrigerant gas (often R-134a or R-410a) to absorb heat from the compressed air and lower its temperature.

Water Cooling: Unlike air-cooled dryers, which use ambient air to dissipate heat, water-cooled dryers use a continuous supply of water to remove the heat generated by the refrigerant. This makes them more efficient in environments where space is limited or where external air cooling isn’t effective.

How Does a Water Cooled Refrigerant Air Dryer Work?

The basic process can be broken down into a few stages:

Compression of Air: Compressed air enters the dryer from the air compressor and passes through a pre-filter to remove large contaminants.

Cooling and Condensation: The air then flows through the evaporator, where it is cooled by the refrigerant. As the temperature drops, the moisture in the compressed air condenses into water.

Water Removal: The condensed water is separated from the air by a separator and drained through an automatic drain valve.

Heat Exchange: The heated refrigerant, now in gaseous form, passes through a condenser where heat is removed by the cooling water supply. This causes the refrigerant to condense back into liquid form, which is then cycled back to the evaporator to repeat the process.

Dry Air Out: After the moisture has been removed, the dry compressed air is then sent out for use in the system.

Advantages of Water Cooled Refrigerant Air Dryers

Water cooled refrigerant air dryers offer several benefits that make them an attractive choice for many industries:

Energy Efficiency: Since these dryers use water as a cooling medium, they are often more energy-efficient than air-cooled dryers, especially in regions with high ambient temperatures. Water has a higher heat capacity than air, so it can absorb more heat with less energy.

Compact Design: Water cooled dryers tend to be more compact because they don’t require large fans or additional ventilation. This is especially beneficial in tight spaces or when there is a need for a quiet operation.

Better Performance in High Ambient Temperatures: In areas where air-cooled dryers struggle due to high temperatures or humidity, water-cooled dryers remain effective since they rely on a separate water supply for cooling, which is often more stable than outdoor air temperatures.

Reduced Environmental Impact: By using water instead of air for cooling, water cooled dryers can have a smaller carbon footprint. Additionally, the use of efficient refrigerants can help reduce the environmental impact of the system.

Lower Noise Levels: Without the need for large fans, water-cooled refrigerant dryers operate at much quieter levels than air-cooled models, making them ideal for use in noise-sensitive environments.

Disadvantages of Water Cooled Refrigerant Air Dryers

While there are many benefits, there are also some downsides to consider:

Water Supply Required: The need for a continuous water supply can be a limitation, particularly if your facility does not have easy access to sufficient water or where water availability is unreliable.

Maintenance of Water Circuit: The water cooling system requires regular maintenance, including monitoring water quality, cleaning the water system, and ensuring proper water flow. Stagnant or contaminated water can lead to efficiency issues or corrosion in the system.

Higher Initial Cost: Water-cooled dryers typically have a higher upfront cost compared to air-cooled dryers due to the additional components and the complexity of the water-cooling system.

Water Treatment: In some regions, water quality may be an issue, and using untreated or hard water in the system could result in mineral buildup, reducing the efficiency of the heat exchanger and other components. Regular water treatment may be necessary to ensure long-term functionality.

Key Considerations When Choosing a Water Cooled Refrigerant Air Dryer

Water Source Availability: Ensure that your facility has access to a reliable water source with consistent flow and temperature. This is especially important in areas where water is scarce or where access to cooling water may be limited.

Size and Capacity: Choose a dryer with the appropriate capacity to match the airflow and moisture load of your compressed air system. Oversized dryers can be inefficient and costly, while undersized units may not perform optimally.

Operating Temperature Range: Check the dryer’s operating temperature range. Water cooled dryers can perform well in higher ambient temperatures, but make sure your system can handle the conditions of your environment.

Maintenance and Serviceability: Look for a dryer with easy access to components like the water cooling system, filters, and condensate drain. Regular maintenance is key to keeping the system running efficiently.

Energy Consumption: While water-cooled dryers tend to be more efficient than air-cooled ones, their energy consumption can still vary based on factors like water temperature, system design, and ambient conditions. Make sure to assess the total energy use of the unit over its lifespan.

Environmental Regulations: Consider any local environmental regulations regarding water usage and refrigerants. Some areas have strict rules on the disposal of wastewater or the types of refrigerants that can be used.

Conclusion

Water cooled refrigerant air dryers are a reliable and energy-efficient solution for maintaining clean, dry air in compressed air systems. They provide consistent performance, especially in hot climates, and offer the advantage of lower noise levels and smaller footprints. However, they require a steady water supply and regular maintenance to ensure optimal performance.

By understanding the advantages, limitations, and key factors involved in selecting a water cooled refrigerant air dryer, you can make an informed decision that enhances the efficiency and longevity of your compressed air system.