In any compressed air system—whether used in industrial machinery, trucks, pneumatic tools, or manufacturing lines—moisture is one of the biggest threats to performance and equipment longevity. To combat this, one component plays a crucial role: the air dryer assembly.

This complete guide explains what an air dryer assembly is, how it functions, what components it includes, and how to choose the right one for your application.

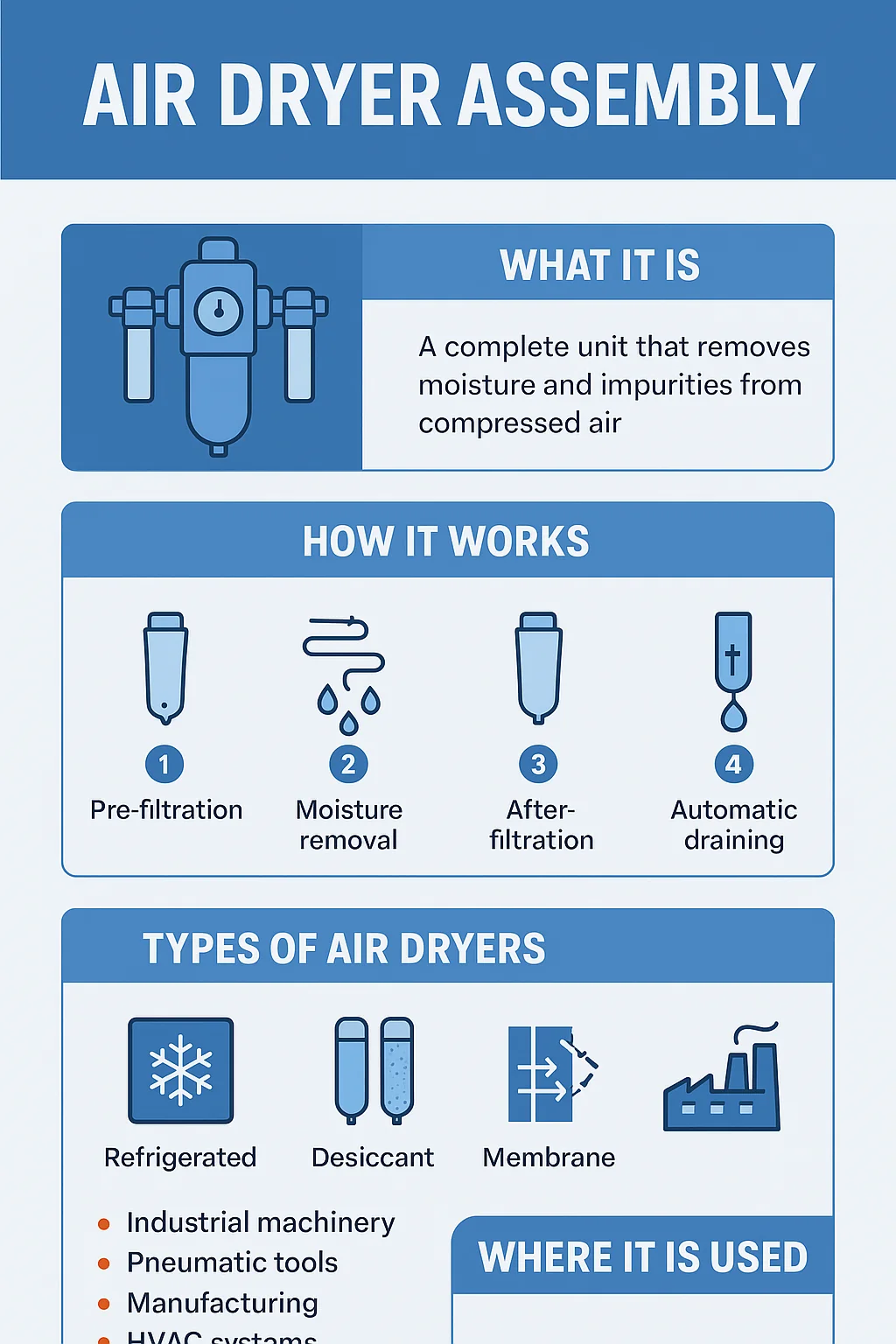

What Is an Air Dryer Assembly?

An air dryer assembly is a complete moisture-removal unit designed to dry and purify compressed air before it reaches downstream equipment. Instead of being a single component, an air dryer assembly is typically a system of integrated parts that work together to deliver clean, dry air.

A standard assembly may include:

Air dryer (refrigerated or desiccant type)

Pre-filter and after-filter

Moisture separator

Drain valve

Pressure regulator

Mounting brackets and fittings

Control components or sensors

Together, these parts remove water vapor, oil aerosols, and contaminants that would otherwise cause corrosion, clogging, and equipment damage.

Why Moisture Control Is Critical

Compressed air always contains some level of water vapor. When the air compresses, the vapor condenses into liquid water—especially in humid environments.

Without a proper air dryer assembly, this moisture can lead to:

Rust and corrosion in pipes

Blocked pneumatic valves

Poor product quality in manufacturing

Malfunctioning air tools

Shortened equipment life

Frozen lines in cold environments

Increased maintenance costs

A high-quality air dryer assembly is an investment in reliability, efficiency, and safety.

How an Air Dryer Assembly Works

While designs vary, most assemblies follow these core stages:

1. Pre-Filtration

Incoming compressed air passes through a pre-filter that removes oil mist, dust, and large contaminants.

2. Moisture Removal

Depending on the type of dryer used, moisture is removed by:

Refrigeration (cooling air to condense water)

Adsorption (desiccant absorbing moisture to very low dew points)

Membrane separation

This step delivers significantly drier air.

3. After-Filtration

Any leftover particulates or desiccant dust are captured by a fine filter.

4. Automatic Draining

Condensed water is expelled via a manual, timed, or zero-loss drain valve.

5. Monitoring & Regulation

Pressure gauges, indicators, or electronic controls ensure stable output and optimal system performance.

Types of Air Dryer Assemblies

1. Refrigerated Air Dryer Assembly

Most common for workshops and general industrial operations

Economical and easy to maintain

Provides a stable dew point around 2–10°C

Suitable for pneumatic tools, automation lines, and machinery

2. Desiccant Air Dryer Assembly

Uses desiccant (alumina, silica gel, or molecular sieve)

Achieves very low dew points (–40°C or lower)

Ideal for high-precision applications, paint lines, and cold climates

Often includes dual-tower regeneration systems

3. Membrane Air Dryer Assembly

Compact and energy-efficient

No electricity needed

Good for point-of-use drying

Suitable for light-duty or mobile applications

Where Air Dryer Assemblies Are Used

Air dryer assemblies are essential in many industries, including:

Automotive repair and body shops

CNC machining

Food and beverage processing

Pharmaceutical manufacturing

Electronics assembly

Truck and trailer air brake systems

HVAC and pneumatic controls

Packaging and printing lines

Any process requiring clean, moisture-free air benefits from a well-designed dryer assembly.

How to Choose the Right Air Dryer Assembly

When selecting an air dryer assembly, consider these key factors:

1. Air Flow (CFM or m³/min)

Choose an assembly capable of handling peak demand without pressure drop.

2. Required Dew Point

General industry → Refrigerated

High-precision or cold environments → Desiccant

Compact, low-demand systems → Membrane

3. Contaminant Levels

If your compressor produces a lot of oil vapor, ensure the assembly includes a high-efficiency coalescing filter.

4. Operating Conditions

Humidity, temperature, and compressor type influence the best dryer option.

5. Maintenance Requirements

Look for:

Easy drain access

Replaceable filters

Long-lasting desiccant

Clear indicators or digital controls

6. Installation Space

Assemblies range from compact wall-mounted systems to large, floor-standing units.

Benefits of a High-Quality Air Dryer Assembly

✔ Protects equipment from corrosion and damage

✔ Improves end-product quality

✔ Reduces downtime and maintenance costs

✔ Enhances pneumatic tool performance

✔ Prevents water contamination in process systems

✔ Extends compressor and valve life

Dry air equals longer-lasting equipment and smoother operation.

Final Thoughts

An air dryer assembly is a vital part of any compressed air system. By removing moisture and contaminants before they reach critical components, it ensures reliability, efficiency, and consistent performance. Whether you’re running a manufacturing plant, a repair shop, or a mobile air system, choosing the right air dryer assembly can dramatically improve your operation while reducing long-term costs.