Have you ever wondered why some beers have that perfect, creamy head and silky-smooth mouthfeel? The secret isn’t just in the hops or yeast—it’s in the gas. While carbon dioxide (CO2) is a classic for its fizzy sensation, nitrogen offers a distinct experience. It creates a dense, long-lasting foam and a less acidic, more balanced taste. This effect is why nitrogen is a game-changer for beer drinkers.

But the use of this versatile gas extends far beyond brewing. This article will explore the broader applications of nitrogen and the essential role of a dedicated nitrogen generator for food and beverage in the modern industry.

The Role of Nitrogen in Enhancing Beer

The subtle influence of nitrogen is key to unlocking exceptional beer flavors. Unlike large CO2 bubbles, nitrogen creates tiny, tight bubbles that produce a cascade effect, leading to a smooth, creamy head that many consumers love. This dense foam is a hallmark of stouts and ales, contributing to both the visual appeal and the sensory experience.

Beyond texture, nitrogen for beer also acts as a natural antioxidant. It displaces oxygen in the keg or bottle, which is a major enemy of freshness and flavor stability. By limiting oxygen exposure, nitrogen helps to preserve the beer’s original character, extending its shelf life and ensuring a consistent taste from the first sip to the last. For brewers, a reliable source of high-purity nitrogen is critical to achieving these results.

To learn more about how our nitrogen generator solutions can elevate your brewing process, visit our website.

The Critical Importance of Purity in Food–Grade Nitrogen Gas

When it comes to beverages and food, the purity of the gas used is non-negotiable. For many applications, including beer, food-grade nitrogen must meet strict quality and safety standards.

According to a broad consensus within the industry, the entry-level requirement for a food-grade nitrogen generator is a minimum purity of 99.5%. However, this is just the beginning.

Professional-grade operations often demand even higher purity levels. Nitrogen purified to above 99.9%—and sometimes as high as 99.999%—provides significant benefits:

- Improved Foam Texture: Higher purity nitrogen results in smaller, more uniform bubbles, enhancing the stability and creaminess of the foam.

- Superior Anti-oxidation: With fewer trace contaminants, the nitrogen more effectively displaces oxygen, leading to better flavor preservation and extended shelf life.

- Enhanced Overall Taste: Impurities can introduce off-flavors or aromas. Using ultra-high purity nitrogen ensures the gas is completely inert and does not alter the intended flavor profile of the beer.

The importance of nitrogen purity in beer is just the tip of the iceberg for nitrogen applications in the food and beverage industry. From packaging preservation to quality enhancement, nitrogen has become an indispensable core element in modern food and beverage manufacturing.

CTA: Discover the technical specifications and purity levels offered by our nitrogen generator for food and beverage systems.

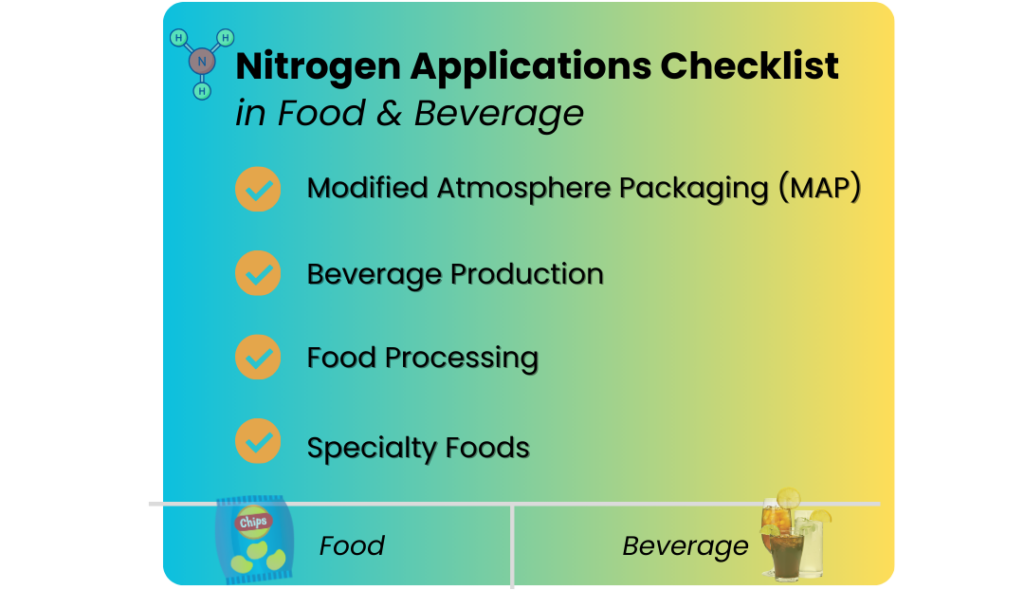

A Comprehensive Look at Nitrogen Applications

(Food & Beverage)

The versatility of nitrogen has made it an essential gas throughout the food and beverage production chain. The most common nitrogen used applications can be categorized as follows:

(1) Modified Atmosphere Packaging (MAP) Applications

MAP is a technique used to extend the shelf life of fresh food products by replacing the atmospheric air inside the package with a precise blend of gases. A nitrogen generator for food packaging is a primary component of this process. Nitrogen is an inert gas, meaning it doesn’t react with food and is highly effective at displacing oxygen, which is the main cause of spoilage, discoloration, and rancidity. This application is widely used for packaged snacks, coffee, nuts, and fresh produce.

(2) Diversified Applications in Beverage Production

Beyond beer, nitrogen plays a key role in a variety of other beverages. It is used to de-gas liquids, helping to remove dissolved oxygen to prevent microbial growth and maintain flavor stability in fruit juices and wine. Additionally, nitrogen is used to dispense beverages, from coffee to cocktails, providing a smooth, non-carbonated pour.

(3) Process Applications in Food Processing

Nitrogen’s inert properties are also invaluable during food processing. In a nitrogen generator for food production factory, nitrogen can be used in a technique called “blanketing.” This involves creating an inert nitrogen atmosphere over a product, protecting it from oxidation during mixing, grinding, or filling. This is a common practice in the production of edible oils, sauces, and pharmaceutical products where product integrity is paramount.

(4) Quality Enhancement for Specialty Foods

Nitrogen is also used for flash freezing, a process known as cryogenics. Because of its extremely low temperature in liquid form, nitrogen can rapidly freeze foods like berries, ice cream, and gourmet meals. This fast freezing prevents the formation of large ice crystals, preserving the cellular structure of the food, which in turn maintains its texture, flavor, and nutritional value. This ensures a high-quality product for the consumer.

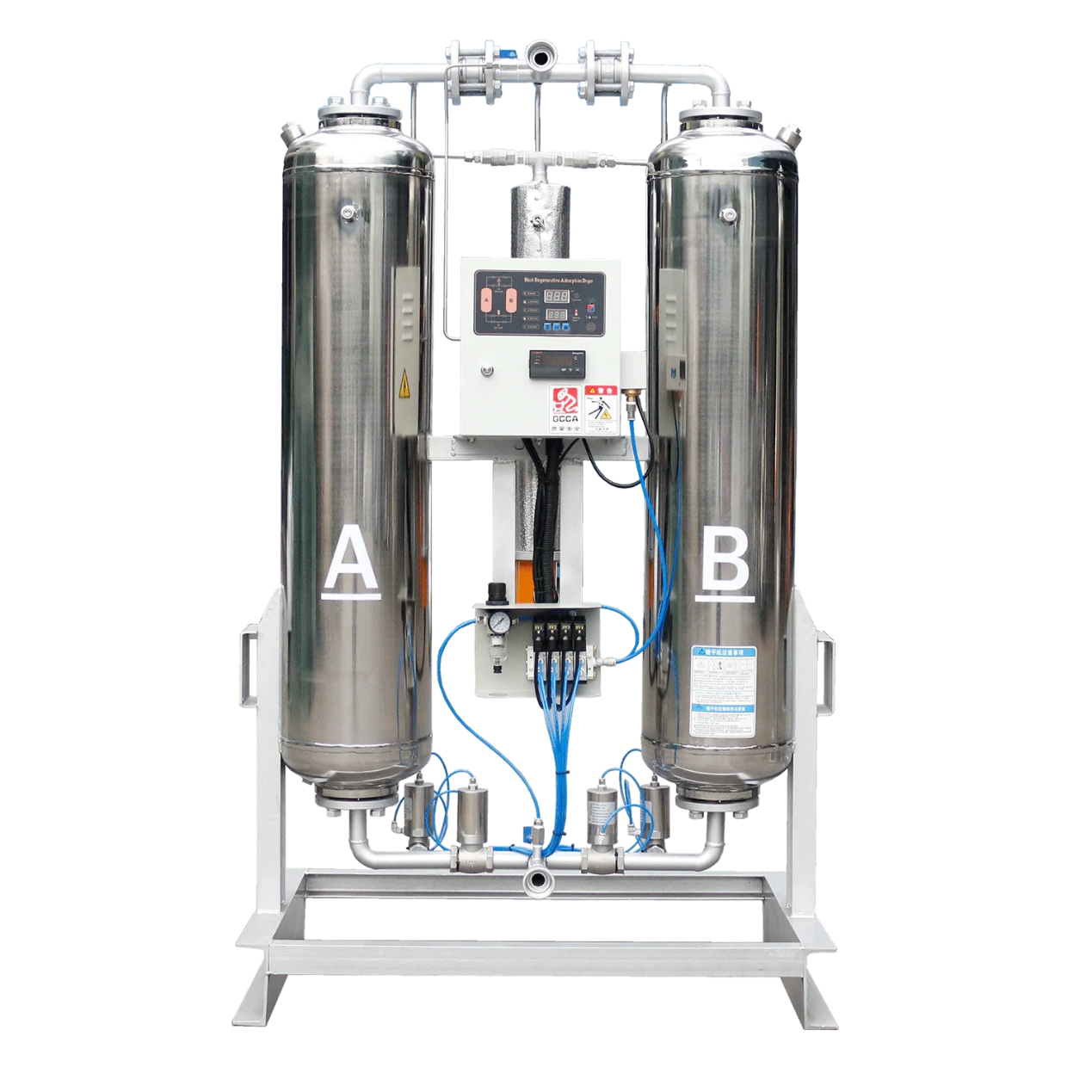

Technology Explained: Nitrogen Generator for Food and Beverage

So, what is a nitrogen generator? Simply put, it is a machine that separates nitrogen from compressed air. It provides a constant, reliable, and cost-effective source of high-purity nitrogen on demand. This eliminates the need for expensive and potentially dangerous high-pressure gas cylinders or cryogenic tanks.

How does a nitrogen generator work? The two main technologies for on-site nitrogen gas generation are Pressure Swing Adsorption (PSA) and Membrane separation.

- PSA Nitrogen Generator:

A PSA nitrogen generatoruses a process called Pressure Swing Adsorption. Compressed air, which is about 78% nitrogen and 21% oxygen, is passed through a vessel containing a carbon molecular sieve (CMS). At high pressure, the CMS selectively adsorbs (or traps) the oxygen and other trace gases, allowing the nitrogen to pass through to a storage tank. When the pressure is released, the trapped gases are vented. The process then switches to a second vessel to ensure a continuous nitrogen supply.

This PSA nitrogen gas generator’s working principle is highly effective for producing high-purity nitrogen, often up to 99.999% purity.

- Membrane Nitrogen Generator:

This technology uses a bundle of hollow-fiber membranes. When compressed air passes through the membrane, different gases permeate through the membrane walls at different rates. The faster-permeating gases, such as oxygen and water vapor, are vented from the side of the membrane, while the slower-permeating nitrogen continues down the length of the fiber and is collected at the end.

Membrane systems are typically more compact and require less maintenance, making them ideal for lower-flow or less-critical applications where ultra-high purity is not required.

For a facility like a large nitrogen generator for a food production factory, a PSA system is often the preferred choice due to its ability to produce high-purity nitrogen at a cost-effective rate. Reputable nitrogen generator manufacturers can provide custom solutions tailored to specific needs.

Learn More: Why Nitrogen Gas Generators Are Vital for Industrial Operations

Why Manufacturers Rely on On-site Nitrogen Generation? And How to Select a System

Choosing an on-site nitrogen generator for sale instead of buying cylinders or dewars boils down to three key advantages: cost, convenience, and control. An on-site nitrogen generator for food and beverage can slash costs by up to 90%, eliminate logistical hassles, and guarantee a steady, reliable supply. This gives manufacturers total control over their gas supply, ensuring both purity and availability.

When considering a nitrogen generator for food and beverage, here are the most important selection criteria:

- Matching Purity Requirements:Purity is critical, especially for food-grade nitrogen. Always choose a system that can meet or exceed your required purity level to ensure product quality and safety.

- Matching the Actual Gas Consumption:It is essential to accurately measure your production line’s gas flow rate. A system that is too small will not keep up with demand, while a system that is too large will be an unnecessary capital expense. A proper system is one that can consistently meet your peak flow requirements.

- Safety and Certification: Given the sensitive nature of the food and beverage industry, any nitrogen generator for food and beverage must be compliant with relevant safety and quality standards, such as those from the FDA or specific food safety certifications.

- 24-Hour Uninterrupted Supply:A robust nitrogen generator for food and beverage should be designed for continuous, 24/7 operation with built-in redundancies and monitoring systems. This ensures a reliable supply, preventing costly interruptions in production.

For a customizable solution that meets these strict requirements, nitrogen generator manufacturers like Lingyu can provide a comprehensive consultation.

For a personalized consultation and a quote on the perfect nitrogen generator for sale for your business, contact us today.