Moisture is one of the biggest threats to any compressed air system. When air is compressed, water vapor becomes concentrated, leading to corrosion, equipment damage, product contamination, and costly downtime. For industries that require extremely dry, high-purity compressed air, a desiccant air dryer system is the most reliable solution.

Unlike refrigerant dryers that remove only moderate levels of moisture, a desiccant system delivers ultra-low dew points as low as –40°C to –70°C, making it ideal for sensitive applications. In this article, we explore what a desiccant air dryer system is, how it works, its advantages, and how to choose the right one.

What Is a Desiccant Air Dryer System?

A desiccant air dryer system (also called an adsorption dryer) uses moisture-absorbing materials—typically activated alumina or molecular sieve—to remove water vapor from compressed air. As humid air passes through a desiccant bed, the desiccant absorbs moisture until it becomes saturated and needs regeneration.

These systems are essential in industries where even minimal moisture can cause serious problems, including:

Pharmaceutical manufacturing

Food and beverage processing

Electronics and semiconductor production

Spray painting and powder coating

Petrochemical and gas plants

Outdoor or cold-climate operations

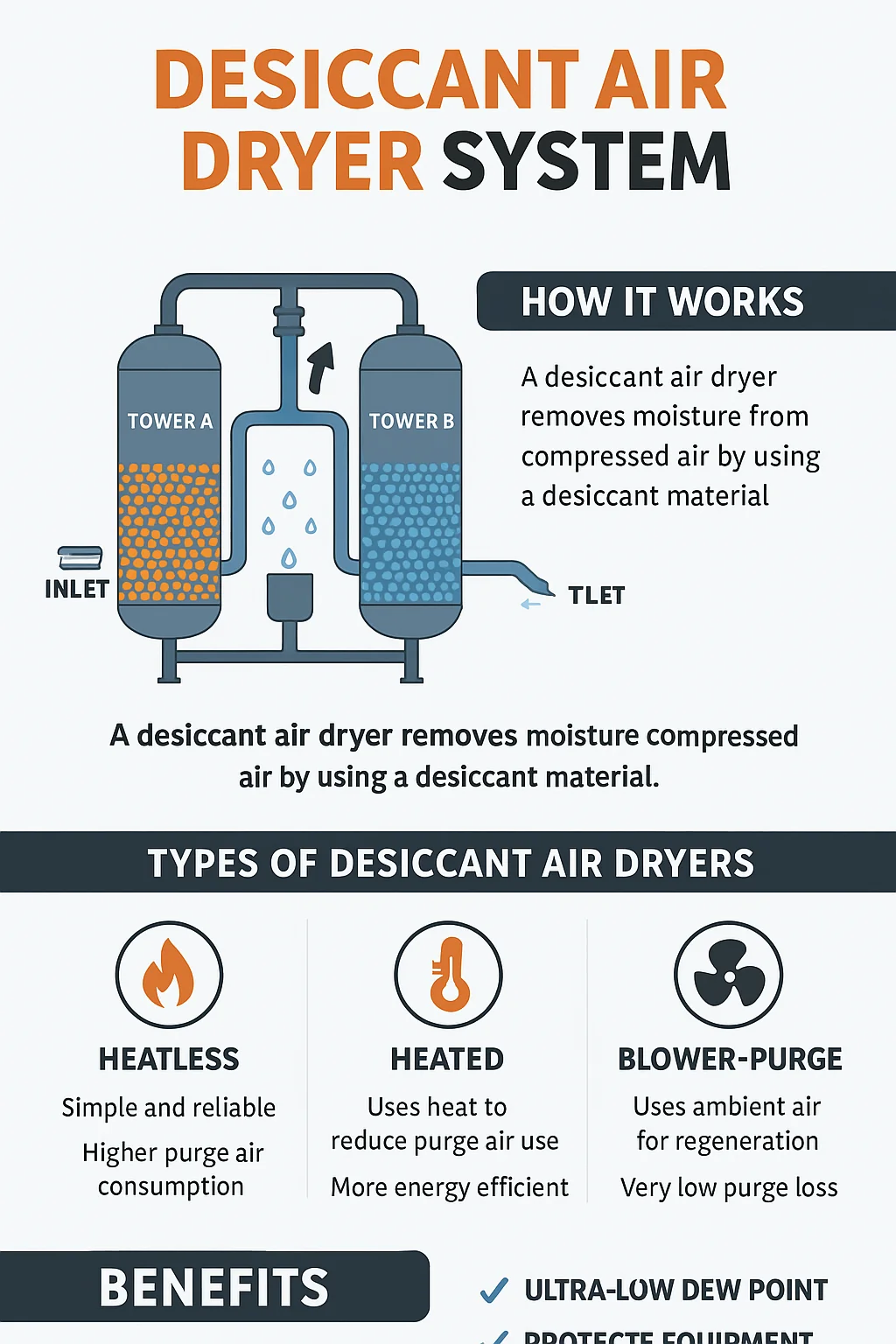

How a Desiccant Air Dryer System Works

Most desiccant dryers operate using a twin-tower design:

1. Tower A – Drying Phase

Compressed air enters Tower A, where the desiccant traps and holds water vapor, delivering dry air with a very low dew point.

2. Tower B – Regeneration Phase

While Tower A is drying the air, Tower B regenerates by releasing the moisture previously absorbed. The system then switches roles in a continuous cycle.

3. Purge Air or Heat Removes Moisture

Depending on the design, moisture is removed using:

Purge air (heatless dryer)

Internal heaters

External heaters with blower air

This continuous regeneration ensures uninterrupted delivery of clean, dry compressed air.

Types of Desiccant Air Dryer Systems

1. Heatless Desiccant Dryers

Use purge air to regenerate the desiccant

Simple and reliable

Best for smaller to mid-sized systems

Higher purge air consumption (approx. 15% of airflow)

2. Heated Desiccant Dryers

Use heaters to regenerate the desiccant

Reduce purge air use

More energy-efficient at higher flow rates

Ideal for large industrial operations

3. Blower-Purge Desiccant Dryers

Use ambient air + heat for regeneration

Very low purge losses

Excellent energy efficiency

Higher upfront cost, lower long-term cost

Advantages of a Desiccant Air Dryer System

✔ Ultra-Low Dew Point

Produces extremely dry air even in freezing temperatures or moisture-sensitive processes.

✔ Protects Equipment and Pipelines

Prevents corrosion, rust, and freezing inside air lines.

✔ Improves Product Quality

Ideal for industries that require 100% clean, ultra-dry air.

✔ Year-Round Performance

Works reliably in both hot and cold climates.

✔ Suitable for Harsh Environments

Performs well in outdoor, high-humidity, and high-risk industrial settings.

Common Applications

A desiccant air dryer system is widely used in:

Instrumentation air systems

Medical and laboratory air

Paint booths and finishing lines

Food processing equipment

Conveyor and packaging systems

Petrochemical and gas refineries

Nitrogen generator feed air

Whenever consistent dryness is required, desiccant dryers outperform all other drying technologies.

How to Choose the Right Desiccant Air Dryer System

When selecting a system, consider:

1. Required Dew Point

–20°C, –40°C, or –70°C depending on your industry requirements.

2. Flow Rate (CFM or m³/min)

Always size the dryer based on maximum possible airflow.

3. Energy Consumption

Heatless models use more purge air; heated models reduce operating costs.

4. Ambient and Inlet Temperature

Higher temperatures require larger or more efficient dryers.

5. Filtration Requirements

Use pre-filters and after-filters to protect the desiccant and ensure air purity.

6. Maintenance Needs

Check desiccant replacement intervals, valve reliability, and drain system performance.

Conclusion

A desiccant air dryer system is an essential investment for any facility that needs dry, clean, and contamination-free compressed air. With ultra-low dew point performance, high reliability, and versatile applications, it ensures your equipment runs smoothly while reducing downtime and maintenance costs.

Whether you operate in pharmaceuticals, manufacturing, electronics, or oil and gas, a high-quality desiccant air dryer system delivers the performance and air purity your operation depends on.