When it comes to protecting your compressed air system, drying the air is just as important as compressing it. Two of the most common drying technologies are desiccant air dryers and refrigerated air dryers. But how do they compare?

This in-depth guide explores desiccant air dryer vs refrigerated systems — their working principles, key differences, pros and cons, and how to choose the right one for your industry.

If you’re deciding between the two, understanding desiccant air dryer vs refrigerated technologies can save you thousands in maintenance costs and ensure consistent, moisture-free air.

🔧 What Is a Desiccant Air Dryer?

A desiccant air dryer removes moisture from compressed air by using a hygroscopic material (desiccant) that adsorbs water vapor. The most common types are heatless and heated regeneration dryers.

Key Features of Desiccant Air Dryers:

Achieves extremely low dew points: -40°C to -70°C

Suitable for critical applications (pharmaceutical, electronics, medical)

Works well in cold or freezing environments

Requires periodic desiccant replacement

Higher operational costs due to regeneration cycles

❄️ What Is a Refrigerated Air Dryer?

A refrigerated air dryer cools the compressed air to around 3°C to 5°C, allowing water vapor to condense and be separated. It’s the most common type of dryer used in industrial applications.

Key Features of Refrigerated Air Dryers:

Typical dew point: +3°C to +10°C

Lower initial and operational cost

Ideal for general-purpose use (automotive, workshops, packaging)

Compact and energy-efficient design

Not suitable for sub-zero or highly critical applications

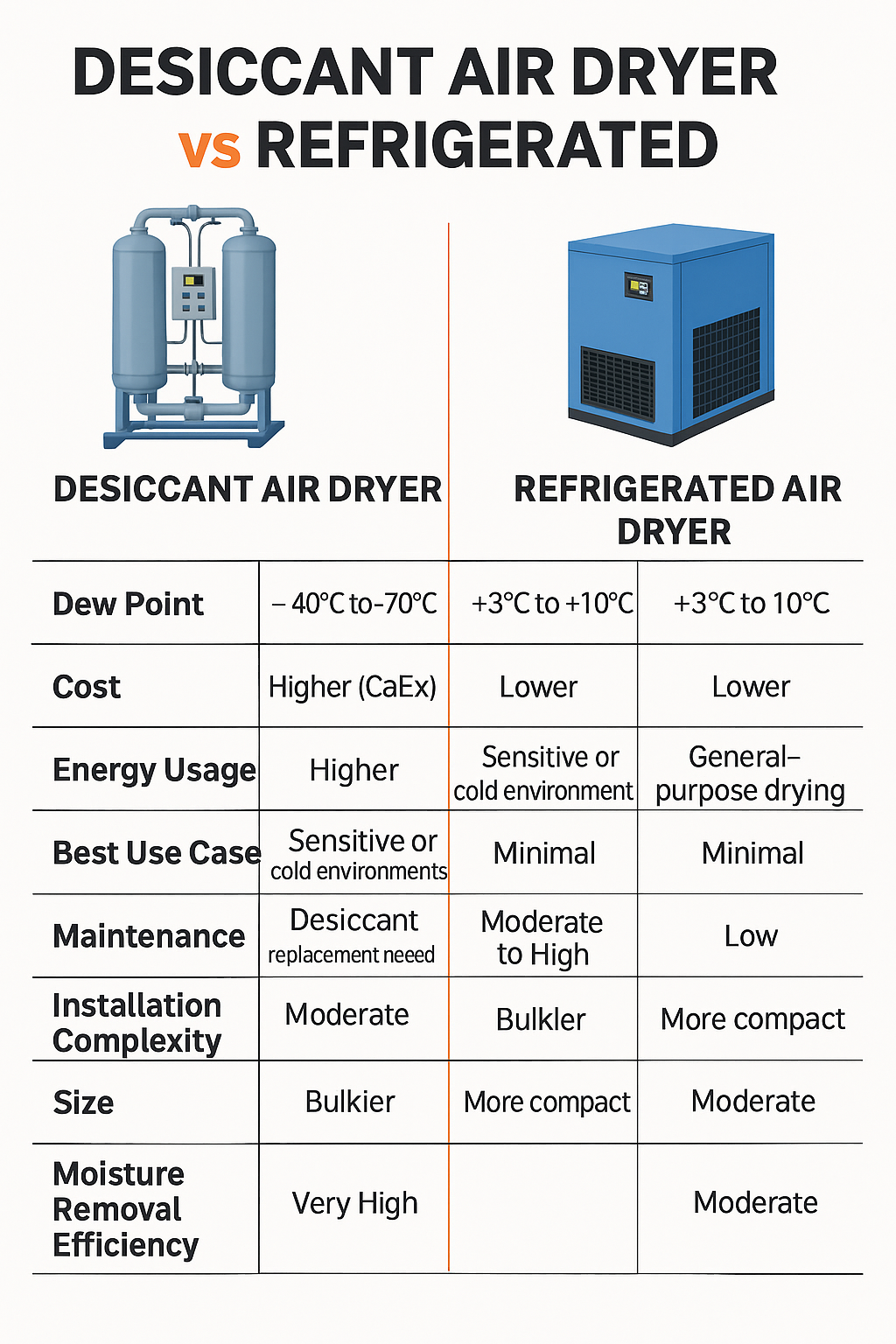

⚙️ Desiccant Air Dryer vs Refrigerated – Comparison Table

| Feature | Desiccant Air Dryer | Refrigerated Air Dryer |

|---|---|---|

| Dew Point | -40°C to -70°C | +3°C to +10°C |

| Cost | Higher (CapEx + OpEx) | Lower |

| Energy Usage | Higher | Lower |

| Best Use Case | Sensitive or cold environments | General-purpose drying |

| Maintenance | Desiccant replacement needed | Minimal |

| Installation Complexity | Moderate to High | Low |

| Size | Bulkier | More compact |

| Moisture Removal Efficiency | Very High | Moderate |

🔍 Desiccant Air Dryer vs Refrigerated – Which One Should You Choose?

Choose a Desiccant Air Dryer If:

You require extremely dry air

You operate in freezing temperatures

Your application involves precision instruments, pharmaceuticals, or electronics

Choose a Refrigerated Air Dryer If:

You operate in moderate climates

You need dry air for general industrial applications

You prioritize lower cost and energy efficiency

Understanding the desiccant air dryer vs refrigerated difference is essential in aligning your compressed air system with operational demands and budget constraints.

📈 Marketing Copy — Discover the Best Air Dryer for Your Needs

Still Choosing Between Desiccant Air Dryer vs Refrigerated? Let Us Help.

At Lingyu, we specialize in tailored air dryer solutions that match your exact needs. Whether you’re seeking ultra-low dew points for pharmaceutical production or energy-saving systems for general industrial use, our engineers will help you navigate the choice of desiccant air dryer vs refrigerated technologies.

🌡️ Desiccant dryers for ultra-dry air (−70°C dew point)

❄️ Refrigerated dryers for efficient, cost-effective performance

💼 Custom sizing, smart control panels, and 24/7 technical support👉 Contact us today to get expert advice and a quote that matches your airflow, pressure, and purity requirements.

❓ FAQ – Desiccant Air Dryer vs Refrigerated

Which is more energy-efficient – desiccant or refrigerated air dryers?

Refrigerated air dryers are more energy-efficient as they don’t require purging or regeneration cycles. Desiccant dryers consume more energy, especially in heat-regeneration models.

Can I use a refrigerated air dryer in cold environments?

Not recommended. Refrigerated dryers perform poorly in sub-zero environments, where the condensed moisture may re-freeze. Desiccant dryers are better suited for cold climates.

How often does desiccant material need to be replaced?

Desiccant materials typically last 3–5 years, depending on usage and air quality. Regular monitoring ensures peak performance.

Is the air quality from a desiccant dryer better than a refrigerated dryer?

Yes. Desiccant dryers provide much lower dew points, ensuring superior air quality suitable for sensitive or moisture-intolerant systems.

Can I combine both dryers in one system?

Yes! Many systems use refrigerated dryers as the primary dryer and desiccant dryers as a polishing stage for critical applications.

📌 Conclusion: The Final Verdict on Desiccant Air Dryer vs Refrigerated

The decision between desiccant air dryer vs refrigerated depends entirely on your application, environment, and performance goals.

| Best for: | Dryer Type |

|---|---|

| Lowest dew point & critical use | Desiccant |

| Cost-effective & general industry use | Refrigerated |

Both technologies have their place in modern compressed air systems. The key is matching the drying performance to your process requirements.

🔍 Want help designing the right system?

📞 Reach out to Lingyu today and get a tailored recommendation on desiccant air dryer vs refrigerated solutions for your specific industry.

Related products:

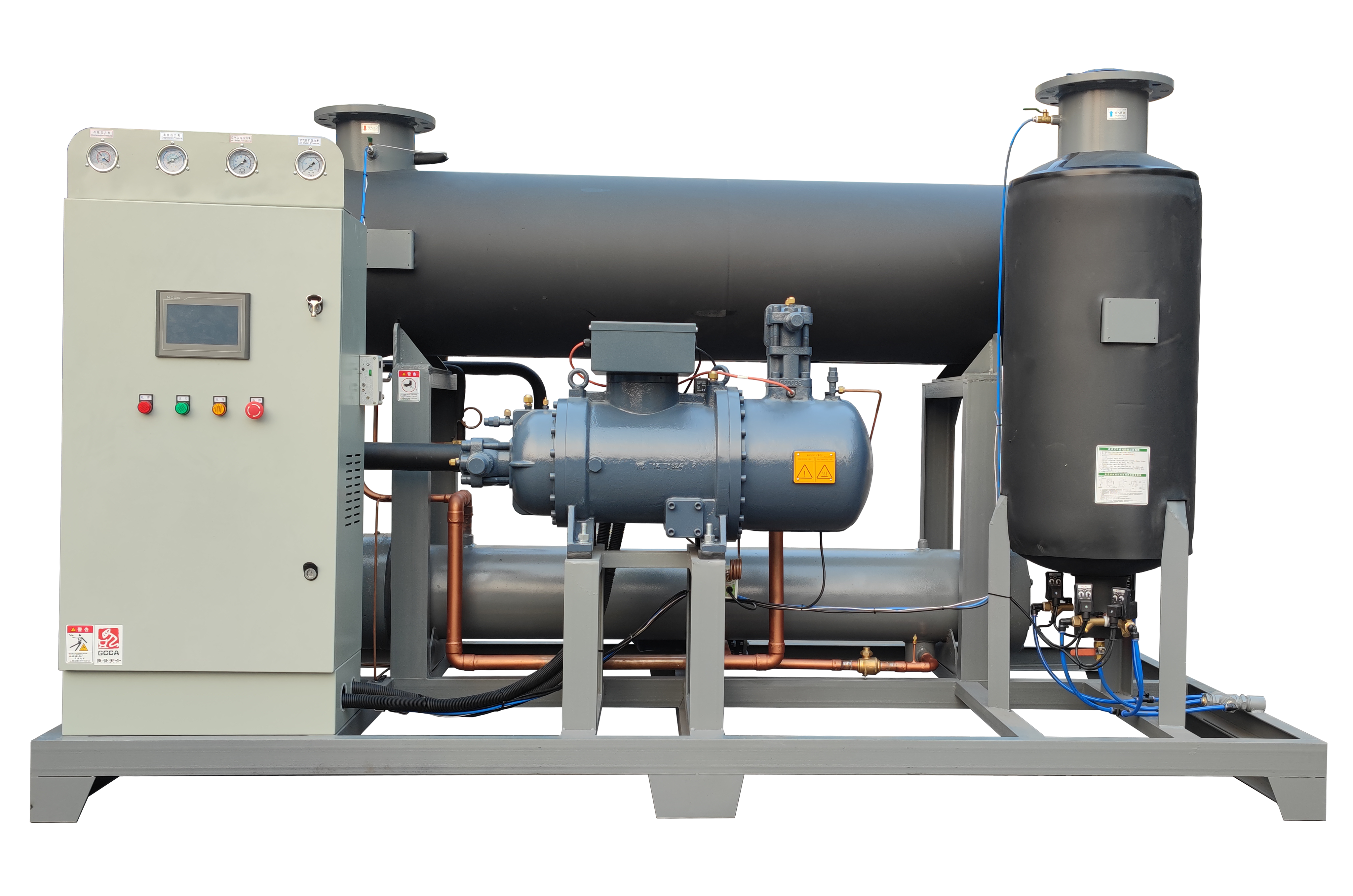

The 3885 CFM refrigerated air dryer (water cooled) is a high-capacity industrial solution designed for removing moisture from large-scale compressed air systems. Built for continuous and demanding operation, this water-cooled unit ensures a steady dew point and maximum system protection. Whether you're operating in petrochemical, steel, manufacturing, or pharmaceutical industries, the 3885 CFM refrigerated air dryer delivers superior drying performance and energy efficiency.

The 4238 CFM refrigerated air dryer (water cooled) is a high-capacity, industrial-grade dryer designed to eliminate moisture from large compressed air systems. Built with a powerful water-cooled refrigeration circuit, this dryer ensures reliable and continuous moisture removal with a stable pressure dew point. For industries that demand high airflow rates and dependable air quality, the 4238 CFM refrigerated air dryer (water cooled) is the ideal solution.

2. Resists chemical corrosion and extends service life

3. Special sealing technology prevents flammable gases or dust from entering theinterior of the machine

4. Regeneration gas consumption can be adjusted, with energy saving and dewpoint adjustment function