Compressed air is a cornerstone of many industrial processes, from manufacturing to food processing and electronics. However, one of the most common challenges in compressed air systems is moisture. Water vapor in compressed air can cause corrosion, reduce equipment lifespan, contaminate products, and even lead to system downtime. This is where desiccant air dryers play a crucial role.

What Are Desiccant Air Dryers?

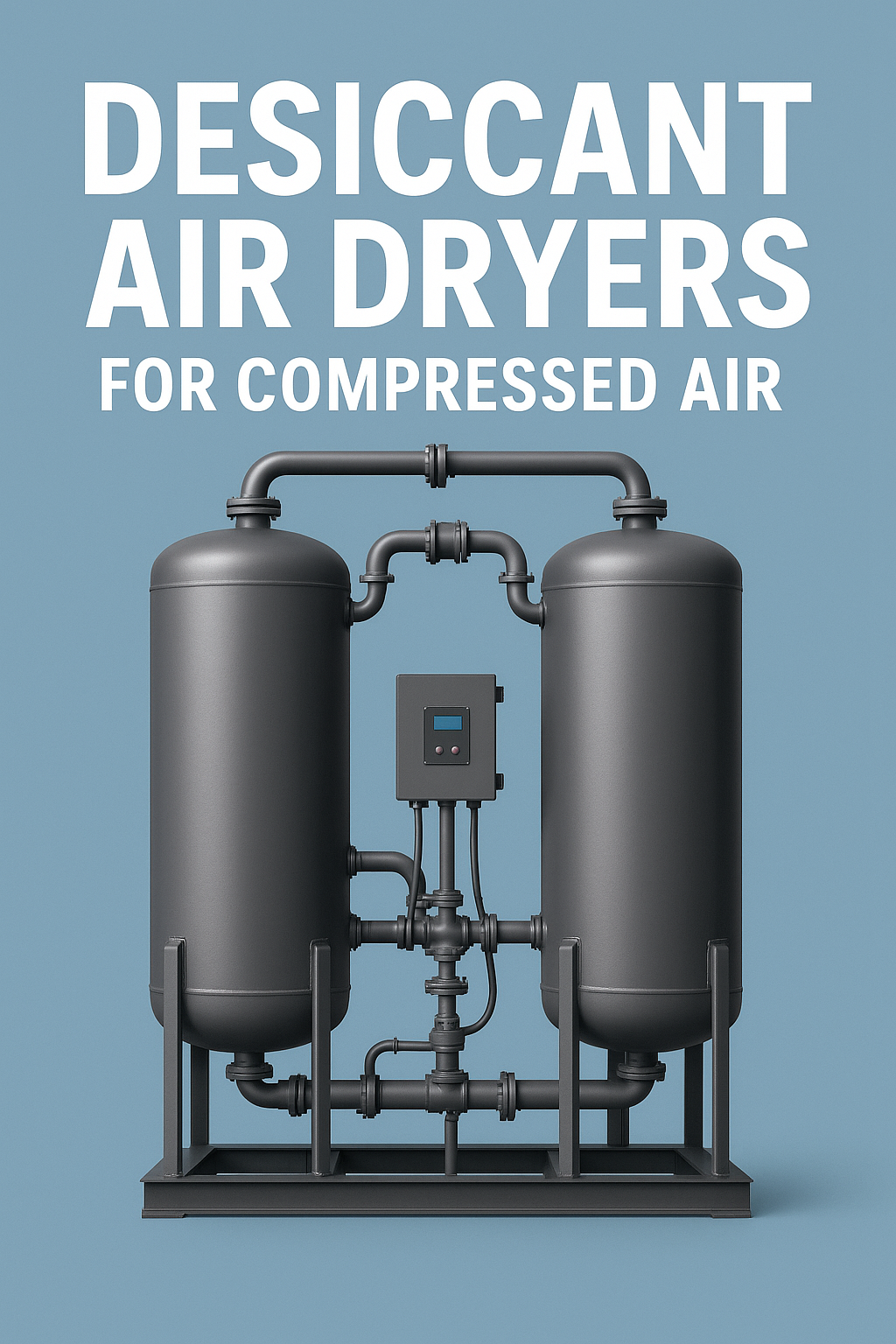

Desiccant air dryers are devices designed to remove moisture from compressed air. Unlike refrigerated dryers, which cool air to condense water, desiccant dryers rely on a material called a desiccant—a substance that naturally absorbs water vapor. Common desiccants include silica gel, activated alumina, and molecular sieves.

These dryers operate using either heatless, heated, or blower purge regeneration methods:

Heatless Desiccant Dryers: Use a small portion of dry compressed air to regenerate the desiccant. They are simple and reliable but consume more compressed air.

Heated Desiccant Dryers: Use external heaters to regenerate the desiccant, reducing compressed air loss.

Blower Purge Desiccant Dryers: Use an external blower to provide regeneration air, making them energy-efficient for large systems.

Benefits of Using Desiccant Air Dryers

Extremely Low Dew Points: Desiccant dryers can achieve dew points as low as -40°F (-40°C) or even -100°F (-73°C), which is essential for critical applications.

Protects Equipment and Products: Dry air prevents rust, corrosion, and damage to pneumatic tools, valves, and sensitive instruments.

Reliability in Extreme Conditions: Desiccant dryers perform well in environments where compressed air may be exposed to very low temperatures.

Long-Term Cost Savings: While the initial investment may be higher than refrigerated dryers, desiccant dryers reduce maintenance costs and prevent costly downtime.

Choosing the Right Desiccant Air Dryer

When selecting a desiccant air dryer, consider:

Air Flow Requirements: Ensure the dryer can handle the system’s peak flow rate.

Pressure Dew Point: Determine the required dryness level for your application.

Operating Conditions: Evaluate temperature, pressure, and environmental factors.

Maintenance and Lifecycle Costs: Assess energy consumption, desiccant replacement, and service requirements.

Conclusion

For industries that demand ultra-dry compressed air, desiccant air dryers are indispensable. They offer superior moisture removal, protect equipment, and ensure the reliability of sensitive processes. Investing in the right desiccant dryer can save significant costs in maintenance, downtime, and product quality issues, making them a smart choice for any industrial compressed air system.