Introduction

In industrial compressed air systems, moisture in the air can cause corrosion in pipelines, reduce the lifespan of pneumatic equipment, and negatively affect product quality. Therefore, drying compressed air is essential in many industrial applications. Air cooled refrigerated air dryers are widely used due to their simple design, ease of maintenance, and moderate energy consumption.

1. Basic Principle

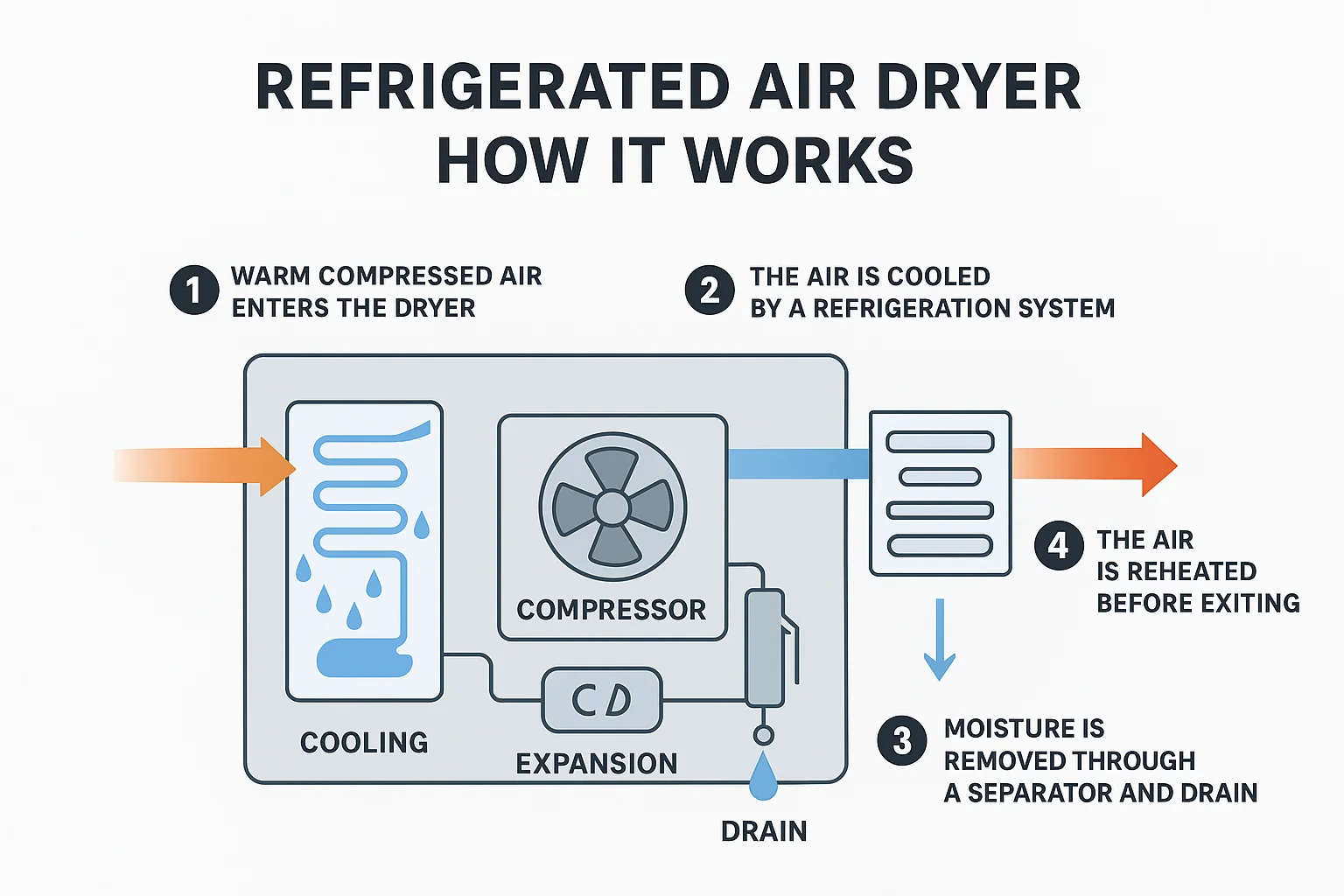

The core principle of an air cooled refrigerated dryer is lowering the air temperature to condense water vapor into liquid water, which is then removed from the system. The process generally consists of three stages:

a、Air Pre-Cooling

Compressed air leaving the compressor is hot (usually 60–80°C) and contains significant water vapor.

The air first passes through an air-to-air heat exchanger or pre-cooler, where its temperature is lowered closer to the operating temperature of the refrigerated dryer.

b、Cooling and Condensation

The air enters the air-cooled condenser, which further reduces the temperature to near freezing (around 3–10°C).

As the air cools, water vapor reaches its dew point and condenses into liquid water.

The condensed water is collected in a separator and drained, leaving significantly drier air.

c、Optional Air Reheating

To prevent condensation or freezing in downstream pipelines, some systems use a reheater to raise the air temperature slightly (typically to 10–15°C).

This protects downstream equipment and ensures consistent air dryness.

2. Main Components of Air Cooled Refrigerated Dryers

Inlet Filter

Removes dust, oil mist, and impurities from the compressed air to prevent clogging the cooler.

Air-Cooled Condenser

Uses ambient air to cool the compressed air and condense moisture.

Eliminates the need for cooling water, ideal for water-scarce environments.

Refrigeration Compressor

Compresses the refrigerant to create a low-temperature environment for air cooling.

Common refrigerants include R134a and R407C.

Expansion Valve / Capillary Tube

Controls refrigerant flow and reduces the temperature in the evaporator.

Air/Refrigerant Evaporator

Compressed air exchanges heat with the refrigerant, cooling further and condensing moisture.

Moisture Separator

Separates condensed water from the air and drains it from the system.

Outlet and Piping

Delivers dry air to downstream equipment at controlled temperature and dew point.

3. Process Flow

Compressed air → Inlet filter →

Air/air pre-cooling →

Evaporator cooling →

Water condensation and separation →

(Optional) Air reheating →

Dry air delivered downstream

Note: Efficiency depends on ambient air temperature; high ambient temperatures may reduce performance.

4. Key Performance Parameters

Dew Point

Typically +3°C to +10°C.

Lower dew point yields drier air but increases energy consumption.

Air Flow Capacity

Measured in Nm³/h; indicates the volume of air the dryer can handle under rated conditions.

Temperature Differential

Indicates cooling efficiency, affecting condensation and dryness of the air.

Power Consumption

Total of refrigeration compressor and fan power, important for energy planning.

5. Advantages and Limitations

Advantages:

No water required; ideal for areas without water access.

Simple design and easy maintenance.

Suitable for medium- and low-pressure compressed air systems.

Limitations:

Performance sensitive to ambient temperature.

Dew point usually cannot go below 0°C.

Cooling depends on airflow and space; ventilation may be required.

6. Summary

Air cooled refrigerated dryers remove moisture from compressed air by cooling it below its dew point and draining the condensed water. Their main advantage is water-free operation and ease of maintenance, while limitations include sensitivity to ambient temperature and limited minimum dew point. Understanding the working principle helps with proper selection, process optimization, and extended equipment lifespan.