Moisture is one of the biggest challenges in industrial compressed air systems. When air is compressed, water vapor condenses into liquid, which can damage machinery, contaminate products, and reduce production efficiency. To solve this problem, manufacturers use an industrial air dryer—a system designed to remove moisture from compressed air and ensure clean, dry, and reliable air supply.

In this article, we explain what an industrial air dryer is, how it works, the main types available on the market, and where it is commonly used.

What Is an Industrial Air Dryer?

An industrial air dryer is a moisture-removal system used in factories and commercial facilities to dry compressed air before it is delivered to equipment or production lines. These dryers are built for heavy-duty operation and offer high airflow capacity, stable dew points, and long-term reliability.

Industrial air dryers prevent:

Corrosion in pipelines and air tools

Damage to machinery and pneumatic equipment

Product contamination from moisture or oil

Reduced efficiency in automation systems

Failures caused by condensation in valves and actuators

In industries where precision and cleanliness matter, dry air is essential.

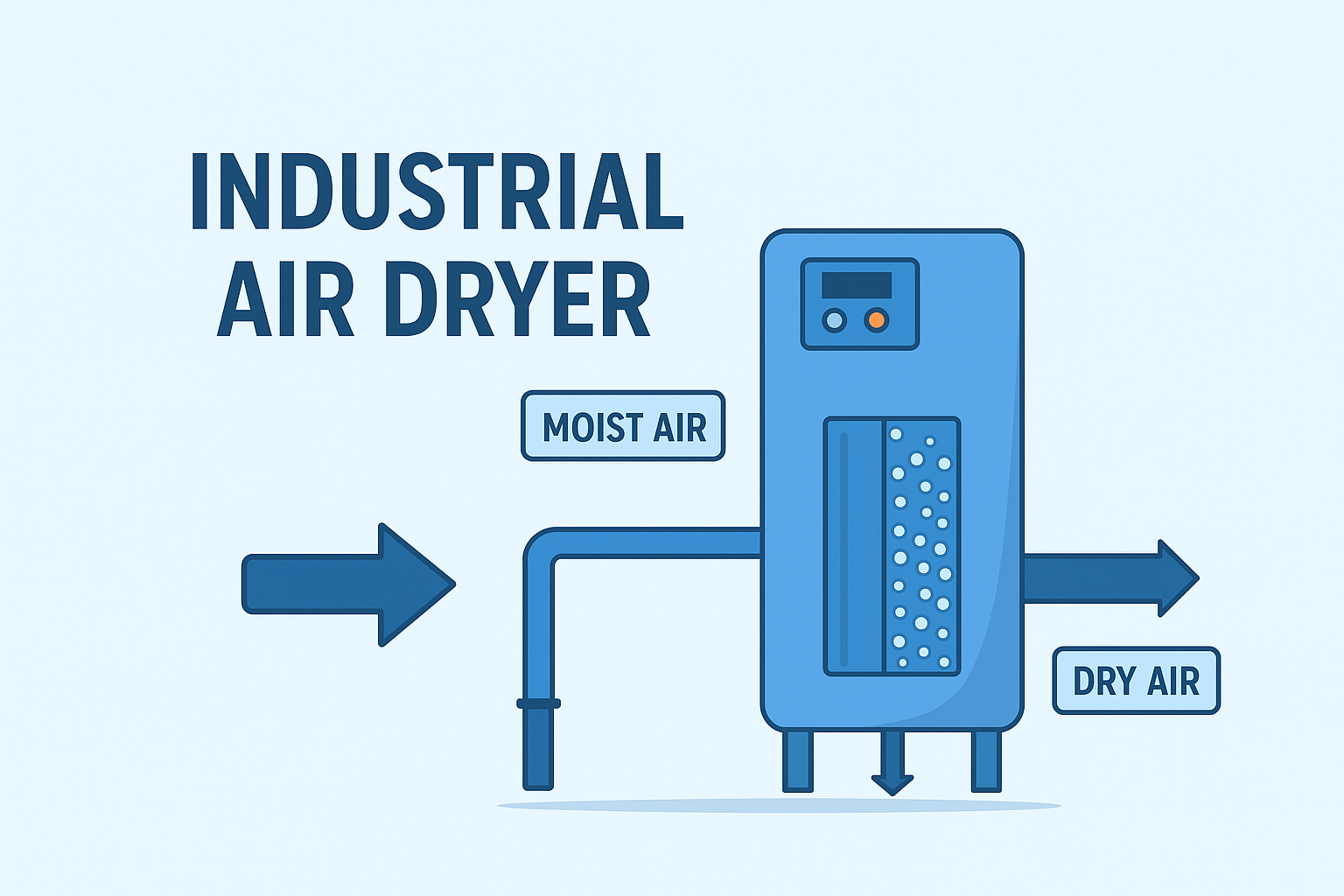

How an Industrial Air Dryer Works

The drying process varies depending on the technology used, but all dryers share the same basic function: remove water vapor from compressed air before it enters the production system.

Typical stages include:

1. Moist compressed air enters the dryer

The air comes directly from an air compressor, usually warm and saturated with vapor.

2. Water is removed by cooling, absorption, or filtration

The dryer uses refrigeration, desiccant materials, or membrane separation to extract moisture.

3. Clean, dry compressed air exits the system

Dry air is then delivered to industrial equipment, preventing rust and performance issues.

4. Drain systems remove collected moisture

Automatic drain valves ensure water does not accumulate inside the dryer.

Types of Industrial Air Dryers

Different industries require different drying levels. Here are the main types:

✔ Refrigerated Air Dryer

Cools air to condense moisture

Economical and widely used

Ideal for general industrial applications

Typical dew point: 2–10°C (35–50°F)

The 3885 CFM water-cooled refrigerated air dryer is an industrial moisture-removal system designed for facilities that require stable and efficient drying performance. Suitable for large compressed air networks, it provides reliable dew point control and long-term protection for downstream equipment in demanding environments.

✔ Desiccant Air Dryer (Adsorption Dryer)

Uses moisture-absorbing materials like activated alumina

Suitable for environments requiring ultra-dry air

Works well in cold climates or sensitive processes

Dew point as low as −40°C to −70°C (−40°F to −94°F)

2., Resists chemical corrosion and extends service life

3. Special sealing technology prevents flammable gases or dust from entering theinterior of the machine

4. Regeneration gas consumption can be adjusted, with energy saving and dewpoint adjustment function

✔ Membrane Air Dryer

Uses selective membranes to remove moisture

Compact, quiet, and energy-efficient

Suitable for small to medium-scale operations

2, Rated inlet pressure: 0.7MPa (0.6MPa~1.0MPa is allowed,other pressure levelsare available for customization)

3. Rated inlet temperature: 10'C~30'C (limit inlet temperature: ≤40°C)

4. Inlet air dew point: <15°C

✔ Heatless & Heated Regeneration Dryers

Designed for large factories needing continuous high-flow dry air

Common in chemical, pharmaceutical, and power industries

Utilizes high-performance pneumatic valves;

Equipped with a fully electronic programmable controller,.

Why Industrial Air Dryers Matter

| Benefit | Impact |

|---|---|

| Protects equipment | Prevents corrosion and premature wear |

| Improves product quality | Prevents moisture contamination |

| Reduces maintenance costs | Fewer failures and part replacements |

| Enhances energy efficiency | Smooth operation with less air loss |

| Ensures reliability in extreme environments | Suitable for low-temperature or high-humidity areas |

Without a proper drying system, air compressors become far less efficient and far more costly to maintain.

Where Industrial Air Dryers Are Used

Industrial air dryers serve critical roles in many fields, including:

Food & beverage manufacturing

Pharmaceutical production

CNC machining and metal processing

Automotive and aerospace industries

Chemical and petrochemical plants

Textile and plastics molding

Packaging and printing industries

Power stations and energy facilities

Any industry requiring clean, dry compressed air benefits from a dryer.

Conclusion

An industrial air dryer is a key component in any factory using compressed air. By removing moisture, it protects machinery, reduces downtime, and ensures high-quality production output. Choosing the right dryer depends on operating conditions, required dew point, air volume, and environmental factors.