Compressed air is essential in many industries—from manufacturing and automotive to food processing and pharmaceuticals. However, one challenge remains constant: moisture. When warm, humid air is compressed, water vapor condenses into liquid, which can damage equipment, contaminate products, and reduce efficiency.

This is where the refrigerated air dryer comes in.

In this article, we’ll explain how a refrigerated air dryer works, why it’s one of the most widely used air-drying technologies, and when it’s the right choice for your system.

What Is a Refrigerated Air Dryer?

A refrigerated air dryer is a device that removes moisture from compressed air by cooling the air to a low temperature, causing water vapor to condense into liquid. The condensed water is then drained out, leaving dry, clean compressed air behind.

This type of dryer is popular because it is:

Reliable

Easy to maintain

Energy-efficient

Suitable for most general industrial applications

How a Refrigerated Air Dryer Works

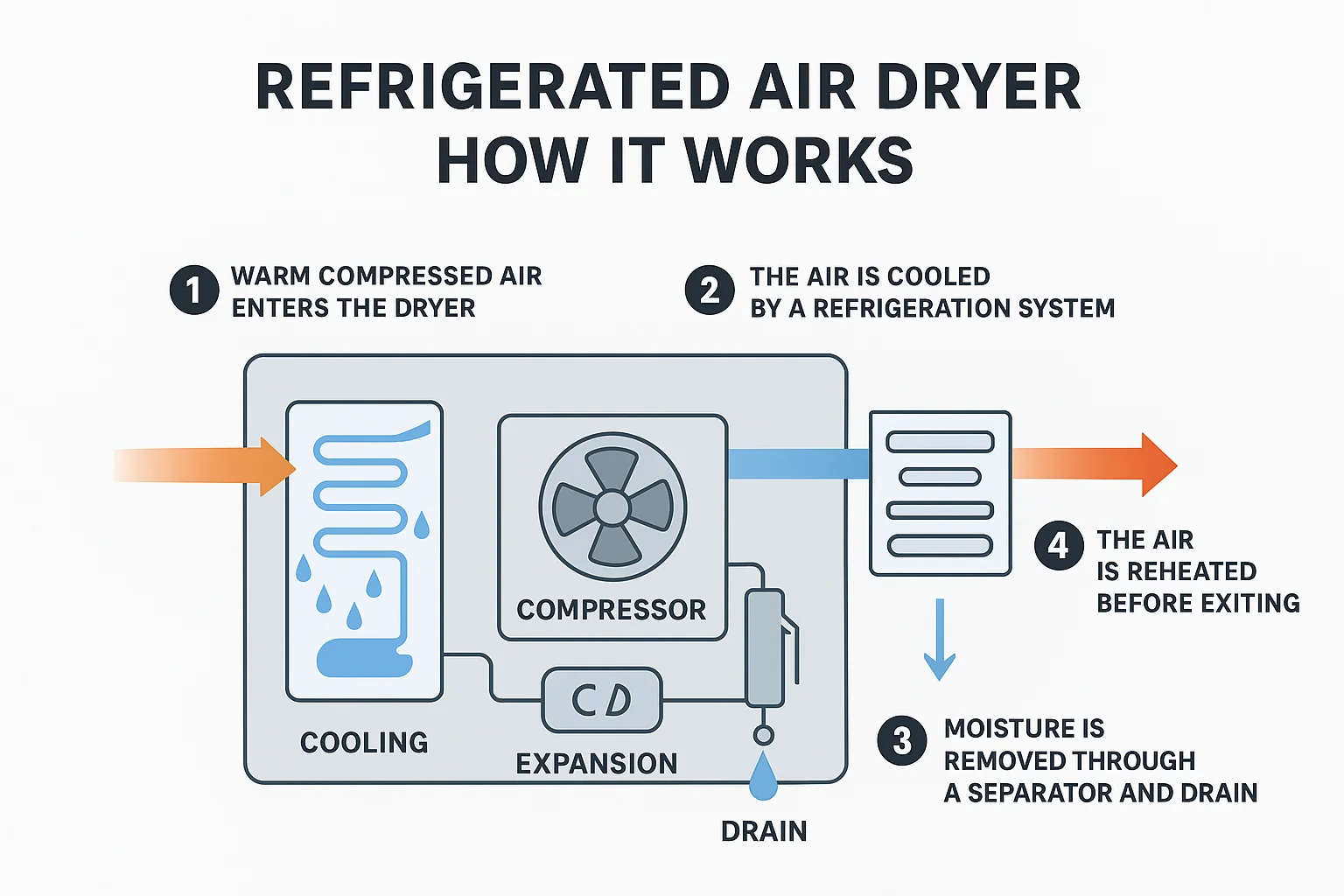

A refrigerated air dryer uses the same basic principles as a household refrigerator or air conditioner. The process typically includes four main stages:

1. Warm compressed air enters the dryer

After leaving the air compressor, the hot, moisture-laden compressed air enters the dryer. Because warm air holds more water vapor, the first step is to cool it down.

2. The air is cooled by a refrigeration system

Inside the dryer is a refrigeration circuit containing components such as:

Evaporator

Compressor

Condenser

Expansion valve

The evaporator cools the compressed air to around 3–10°C (37–50°F).

At this temperature, the water vapor in the air condenses into liquid droplets.

3. Moisture is removed through a separator and drain

Once condensed, the liquid water is extracted using a moisture separator.

Then, an automatic drain valve removes the accumulated water from the system, preventing it from re-entering the airstream.

4. The air is reheated before exiting

After moisture removal, the cold, dry air passes through a heat exchanger where it is reheated by incoming warm air.

This step improves energy efficiency and prevents condensation from forming on downstream pipes.

The result is clean, dry compressed air with a typical dew point of 2–10°C, which is sufficient for most industrial applications.

Types of Refrigerated Air Dryers

There are two main types:

1. Non-cycling refrigerated dryers

Run continuously

Simple and cost-effective

Best for steady air demand

2. Cycling refrigerated dryers

Adjust cooling based on airflow

More energy-efficient

Ideal for fluctuating demand

Come and choose your product

Advantages of Refrigerated Air Dryers

Affordable to operate

Low maintenance requirements

Stable dew point for general use

Long service life

They are an excellent choice for applications where ultra-dry air (e.g., −40°C dew point) is not required.

Common Applications

Refrigerated air dryers are widely used in:

Automotive workshops

Food and beverage plants

Packaging and printing

CNC machining

Textile manufacturing

Plastic molding

General factory air systems

Conclusion

Understanding how a refrigerated air dryer works helps you maintain a reliable and efficient compressed air system. By cooling the air and removing moisture, these dryers prevent corrosion, improve product quality, and extend equipment life—making them an essential part of industrial operations.