In industrial compressed air systems, moisture control is critical to ensuring equipment reliability, product quality, and overall system longevity. While refrigeration dryers are suitable for moderate dew point requirements, industries that demand extremely dry air—such as pharmaceuticals, electronics, food processing, and chemical manufacturing—often rely on adsorption (desiccant) air dryers.

Among the various desiccant dryer technologies available, blower heated adsorption air dryers have emerged as one of the most energy-efficient and cost-effective solutions for delivering consistently low dew points. This guide provides a complete overview of how blower heated dryers work, their benefits, limitations, selection criteria, and where they are most effectively used.

What Is a Blower Heated Adsorption Air Dryer?

A blower heated adsorption air dryer (often called a “blower purge dryer”) is a desiccant-based dryer that uses heated ambient air from a blower—instead of using compressed air—to regenerate the desiccant material. This significantly reduces compressed air loss while maintaining dew points as low as –40°C (–40°F) or even –70°C (–94°F).

How It Works at a Glance

Moisture is removed from compressed air as it passes through a desiccant-filled tower.

Regeneration of the desiccant is performed using a blower and external heater, rather than using the compressed air itself.

This results in substantial energy savings, especially for large-scale operations.

How Blower Heated Adsorption Dryers Work

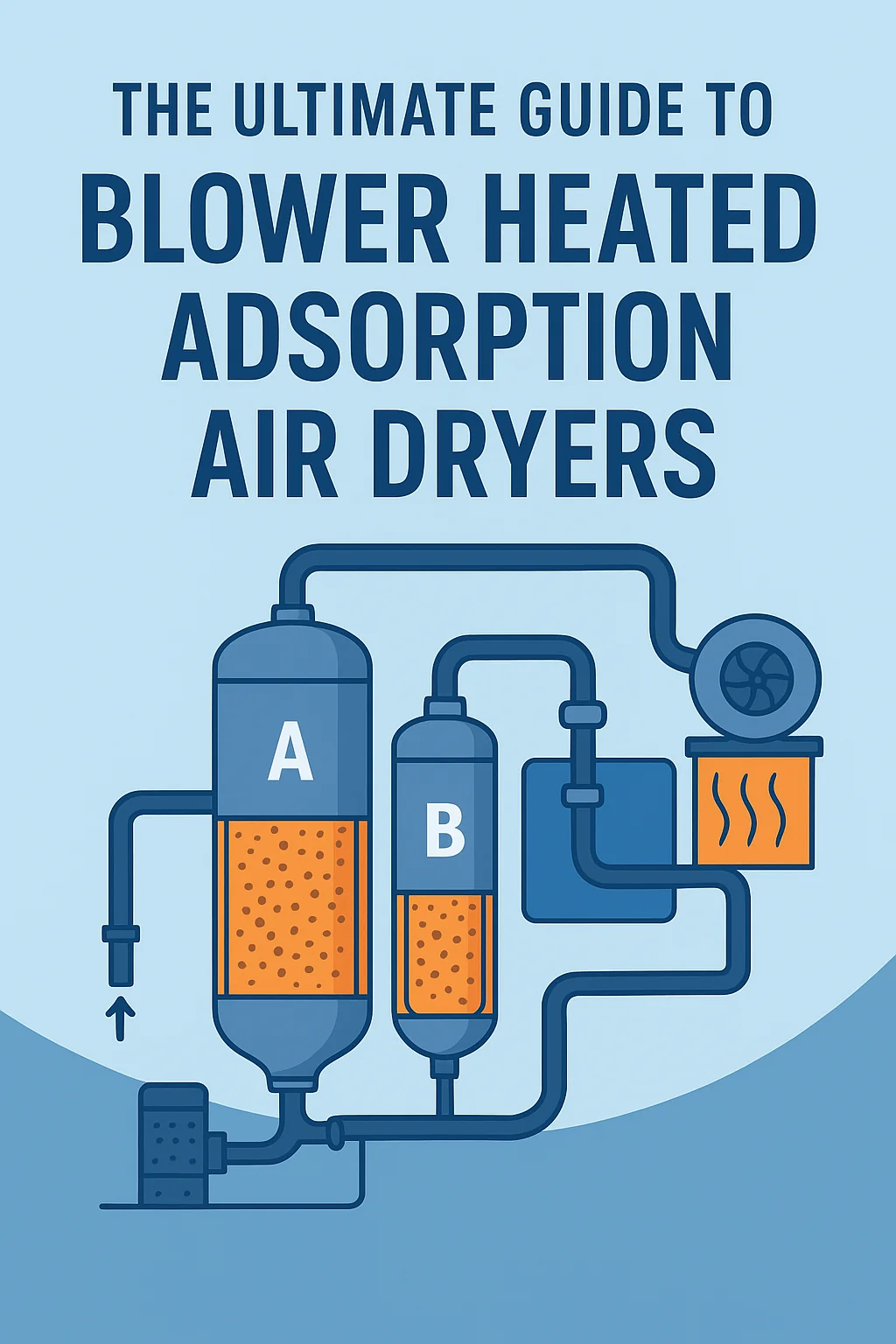

Blower heated dryers typically operate using a dual-tower design with continuous cycling between drying and regeneration modes.

1. Adsorption (Drying Phase)

Compressed air enters Tower A, flowing through desiccant beads such as activated alumina or silica gel.

The desiccant adsorbs water vapor, producing extremely dry outlet air.

Meanwhile, Tower B undergoes regeneration.

2. Regeneration Stage

Regeneration consists of three sub-phases:

a. Heating with Blower Air

A blower draws ambient air (not compressed air).

The air is heated using an electric heater or steam heater.

The hot air flows through Tower B, evaporating moisture from the desiccant.

b. Cooling Phase

After heating, ambient air is blown through the desiccant to cool it down before switching back to drying mode.

Cooling ensures the desiccant does not introduce heat into the compressed air stream.

3. Tower Switch

Tower B becomes the drying tower.

Tower A enters regeneration.

The cycle repeats continuously.

Advantages of Blower Heated Adsorption Air Dryers

Blower heated dryers offer several key advantages over heatless and externally heated systems:

1. Significant Energy Savings

Uses ambient air instead of compressed air for regeneration.

Reduces compressed air loss from 15–20% (typical in heatless dryers) to 2–5%, or in some cases zero purge air.

2. Very Low Operating Cost

Ideal for large flow rates where purge air loss would be extremely costly.

Combined blower + heater regeneration is more energy-efficient than pure heater-only regeneration.

3. Consistently Low Dew Points

Achieves dew points as low as:

–40°C / –40°F (standard)

–70°C / –94°F (with special desiccant & control options)

Suitable for sensitive industrial applications requiring ultra-dry air.

4. Longer Desiccant Life

Regeneration temperatures are carefully controlled.

Lower thermal stress results in extended desiccant service life—often 3–5 years or more.

5. Reduced Environmental Impact

Lower energy consumption means:

Reduced CO₂ emissions

Smaller carbon footprint

Less frequent desiccant replacement reduces solid waste.

Disadvantages of Blower Heated Adsorption Air Dryers

While blower heated dryers offer impressive benefits, they also come with some operational considerations:

1. Higher Initial Cost

Equipment cost is higher due to:

Blower

Heater

Advanced control systems

However, the payback is often rapid due to lower operating costs.

2. Requires Stable Ambient Conditions

Regeneration air comes from the ambient environment.

Very humid or hot environments can reduce regeneration efficiency.

3. Increased System Complexity

Blower, heater, cooling valves, and controls require regular maintenance.

More components mean more potential failure points.

4. Larger Physical Footprint

Blower and heater assemblies require more space than heatless dryers.

Key Considerations When Selecting a Blower Heated Adsorption Air Dryer

To choose the right unit, consider the following factors:

1. Required Dew Point

Standard industrial: –40°C (–40°F)

Critical applications: –70°C (–94°F)

Ensure the dryer is rated for your dew point target.

2. Airflow Capacity

Match the dryer to your compressor output (SCFM/Nm³/hr). Over-sizing increases cost; under-sizing leads to poor performance.

3. Ambient Conditions

Evaluate:

Ambient temperature

Ambient humidity

Available heating power (electric, steam, gas)

These factors affect regeneration efficiency.

4. Energy Consumption

Look for:

Low blower power consumption

High heater efficiency

Built-in dew point control (saves energy by extending cycles)

5. Maintenance Requirements

Consider units that offer:

Easy desiccant replacement

Accessible filtration systems

Smart control panels for diagnostics and alarms

6. Total Cost of Ownership (TCO)

Evaluate:

Initial cost

Energy cost

Maintenance and desiccant replacement frequency

Payback time vs. heatless or heated purge dryers

Applications of Blower Heated Adsorption Air Dryers

Blower heated dryers are ideal for facilities with high flow rates and strict dew point requirements, such as:

Pharmaceutical manufacturing

Food and beverage production

Semiconductor and electronics

Automotive spraying and coating

Chemical and petrochemical plants

Instrument and process air

Power plants

Any process requiring ultra-dry air at minimal operating cost benefits from blower heated dryers.

Conclusion

Blower heated adsorption air dryers combine low operating cost, high energy efficiency, and consistent dew point performance, making them one of the best solutions for industrial moisture control. Although they come with higher upfront investment and additional complexity, the long-term savings and reliability often justify the cost—especially for large-scale applications.

By understanding their operation, advantages, limitations, and selection criteria, you can make an informed decision that enhances the productivity, efficiency, and durability of your compressed air system.