In industrial environments where high-quality compressed air is essential, moisture control plays a critical role in maintaining operational reliability, reducing equipment wear, and ensuring product quality. While many desiccant dryer technologies exist—such as heatless, heated purge, and blower heated types—compression heated adsorption air dryers stand out as a highly efficient option that takes advantage of the heat already generated during air compression.

This ultimate guide explains what compression heated dryers are, how they work, their advantages and limitations, and how to choose the best system for your facility.

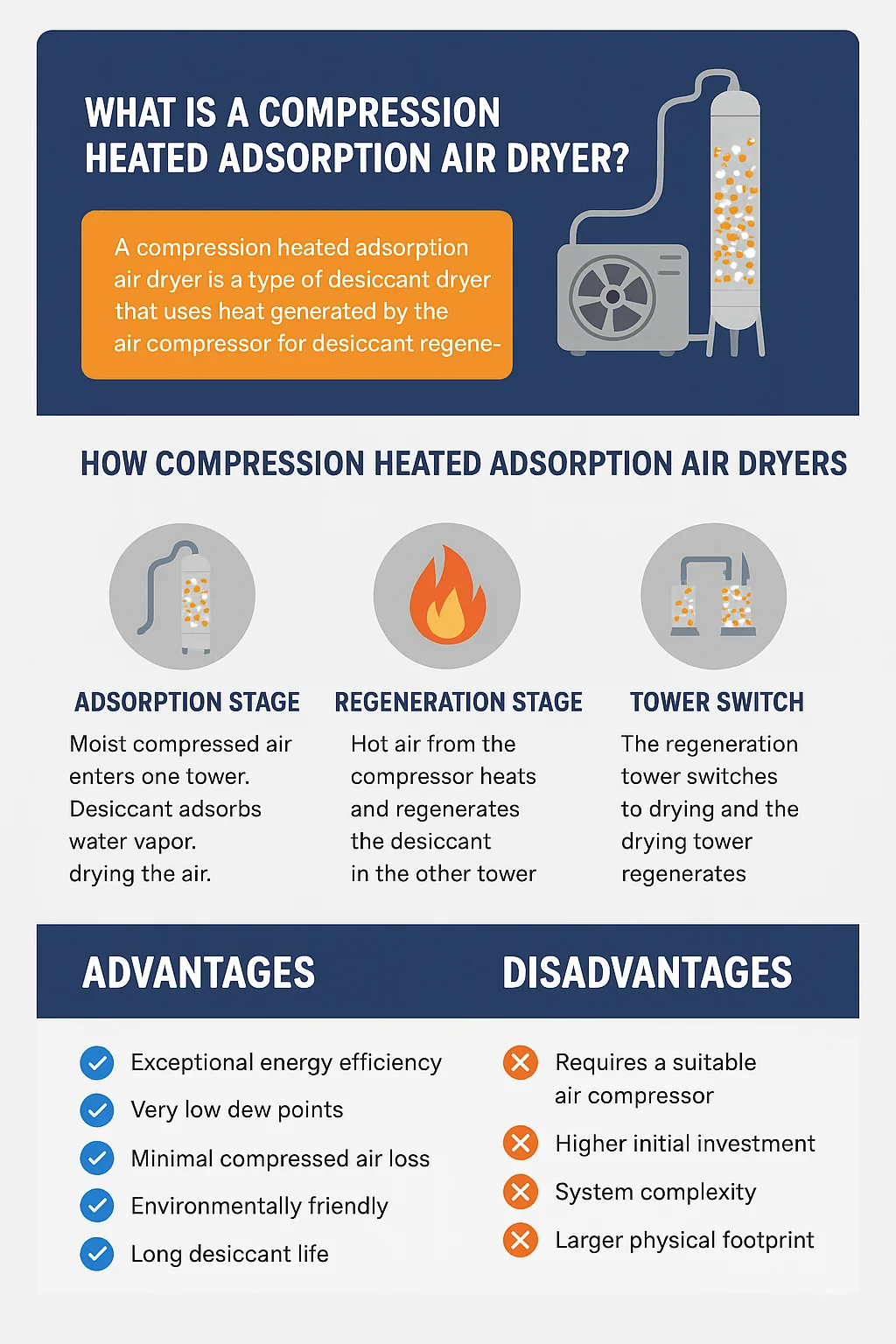

What Is a Compression Heated Adsorption Air Dryer?

A compression heated adsorption air dryer (also known as a “compressor-heat regenerated dryer”) is a type of desiccant air dryer that uses the heat generated by the air compressor itself for desiccant regeneration. Unlike many other dryer types that rely on electric heaters or purge air, compression heated dryers recover and reuse compressor heat, significantly reducing energy consumption.

These systems are commonly paired with oil-free compressors, especially two-stage or centrifugal units, which deliver hot air suitable for regeneration.

Typical Dew Point Performance

–20°C to –40°C (–4°F to –40°F) standard

–70°C (–94°F) possible with advanced designs

This makes compression heated dryers an excellent choice for applications requiring very dry, consistent compressed air.

How Compression Heated Adsorption Air Dryers Work

Compression heated dryers typically operate in a dual-tower configuration, with one tower drying air while the other undergoes regeneration.

Below is a simplified breakdown of the process.

1. Adsorption Stage (Drying Phase)

Moist compressed air enters Tower A.

Desiccant media—such as activated alumina or silica gel—adsorbs water vapor.

The resulting dry air exits toward the air distribution system.

2. Regeneration Stage (Heat + Cooling)

Compression heated dryers regenerate desiccant using the heat of compression, rather than external electric heaters.

a. Heating Phase

Hot, high-temperature air from the compressor (often 300–400°F / 150–200°C) is diverted into Tower B.

The heat evaporates moisture trapped in the desiccant.

b. Cooling Phase

After heating, the regenerated tower must be cooled before switching back online:

Cooling is performed using:

Ambient air (in some designs)

A small amount of dry purge air

A closed-loop cooling system

Cooling ensures the desiccant won’t reintroduce heat or moisture into the dry air system.

3. Tower Switch

Once Tower B is regenerated and cooled:

Tower B becomes the drying tower.

Tower A switches to regeneration.

This continuous cycling ensures a constant supply of ultra-dry air.

Advantages of Compression Heated Adsorption Air Dryers

Compression heated dryers offer several unique benefits that make them stand out among desiccant technologies.

1. Exceptional Energy Efficiency

✔ Uses existing compressor heat

✔ Minimizes or eliminates electric heater use

✔ Reduces purge air consumption

This results in the lowest operating cost of any desiccant dryer type when paired with the right air compressor.

2. Very Low Dew Points

Consistent dew point levels: –20°C to –70°C

Suitable for highly sensitive industries like pharmaceuticals and electronics

3. Minimal Compressed Air Loss

Unlike heatless dryers that consume 15–20% purge air:

Compression heated dryers typically consume 0–5%, depending on the cooling design.

This dramatically increases compressor efficiency.

4. Environmentally Friendly

Reuses waste heat

Low energy demand

Reduced carbon footprint compared to heated purge or blower heated dryers

5. Long Desiccant Life

Lower thermal shock and controlled heating cycles result in:

Extended desiccant lifespan

Fewer maintenance interruptions

Long-term cost savings

Disadvantages of Compression Heated Adsorption Air Dryers

Despite their strong performance, these systems also have limitations.

1. Requires a Suitable Air Compressor

Compression heated dryers are typically:

Used with oil-free air compressors

Paired with compressors capable of delivering reliable high discharge temperatures

Oil-flooded compressors are usually incompatible due to oil cooling the discharge air.

2. Higher Initial Investment

The upfront cost is higher due to:

Advanced heat-recovery designs

Complex flow controls

Integration with the compressor system

However, operating cost savings often offset the initial investment.

3. System Complexity

These dryers rely on:

Temperature control

Heat recovery routing

Multiple valves and monitoring systems

Regular maintenance and skilled technicians are required.

4. Larger Footprint

Compared to heatless dryers, compression heated dryers may require additional piping and heat-management components.

Key Considerations When Choosing a Compression Heated Dryer

To select the ideal system for your facility, consider the following:

1. Compressor Type and Compatibility

Ensure your compressor is designed for heat-of-compression recovery.

Best matches include:

Oil-free rotary screw compressors

Oil-free scroll compressors

Centrifugal compressors

2. Required Dew Point

Verify that the dryer can meet your dew point target reliably:

Standard: –40°C

Critical: –70°C

3. Airflow Capacity

Proper sizing is essential:

Oversizing increases energy consumption

Undersizing reduces dew point performance

4. Ambient Conditions

Evaluate:

Ambient temperature and humidity

Room ventilation

Cooling water availability (if used)

These affect regeneration and cooling efficiency.

5. Energy Analysis

Calculate:

Purge air savings

Heater elimination savings

ROI compared to heatless or blower heated dryers

Compression heated dryers often deliver the fastest payback in high-volume systems.

6. Maintenance and Accessibility

Look for:

Easy access to desiccant beds

Modular valve assemblies

Smart control panels with diagnostics

Dew point monitoring

Applications of Compression Heated Adsorption Air Dryers

These dryers excel in industries requiring high air purity with minimal energy cost:

Pharmaceutical manufacturing

Electronics and semiconductor production

Food & beverage processing

Chemical and petrochemical plants

Automotive painting and robotics

Instrumentation and control air

Power generation

Conclusion

Compression heated adsorption air dryers offer one of the most energy-efficient, environmentally friendly, and reliable methods of producing ultra-dry compressed air. By reusing the heat already generated by the compressor, they dramatically reduce operating costs while maintaining exceptional drying performance.

Although they require compatible compressors and involve higher initial investment, the long-term savings, low purge air loss, and superior dew point stability make them a strong choice for modern industrial facilities.